Natural gas engine structure for mixed double-injection of cylinder outer cold water and in-cylinder hot water

A natural gas and external cold water technology, applied in the direction of internal combustion piston engine, gaseous engine fuel, engine components, etc., can solve the problems of knocking nitrogen oxides, limiting the thermal efficiency of internal combustion engines, and increasing power, and achieves suppression of knocking and super knocking, The effect of improving fuel economy and emission characteristics, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

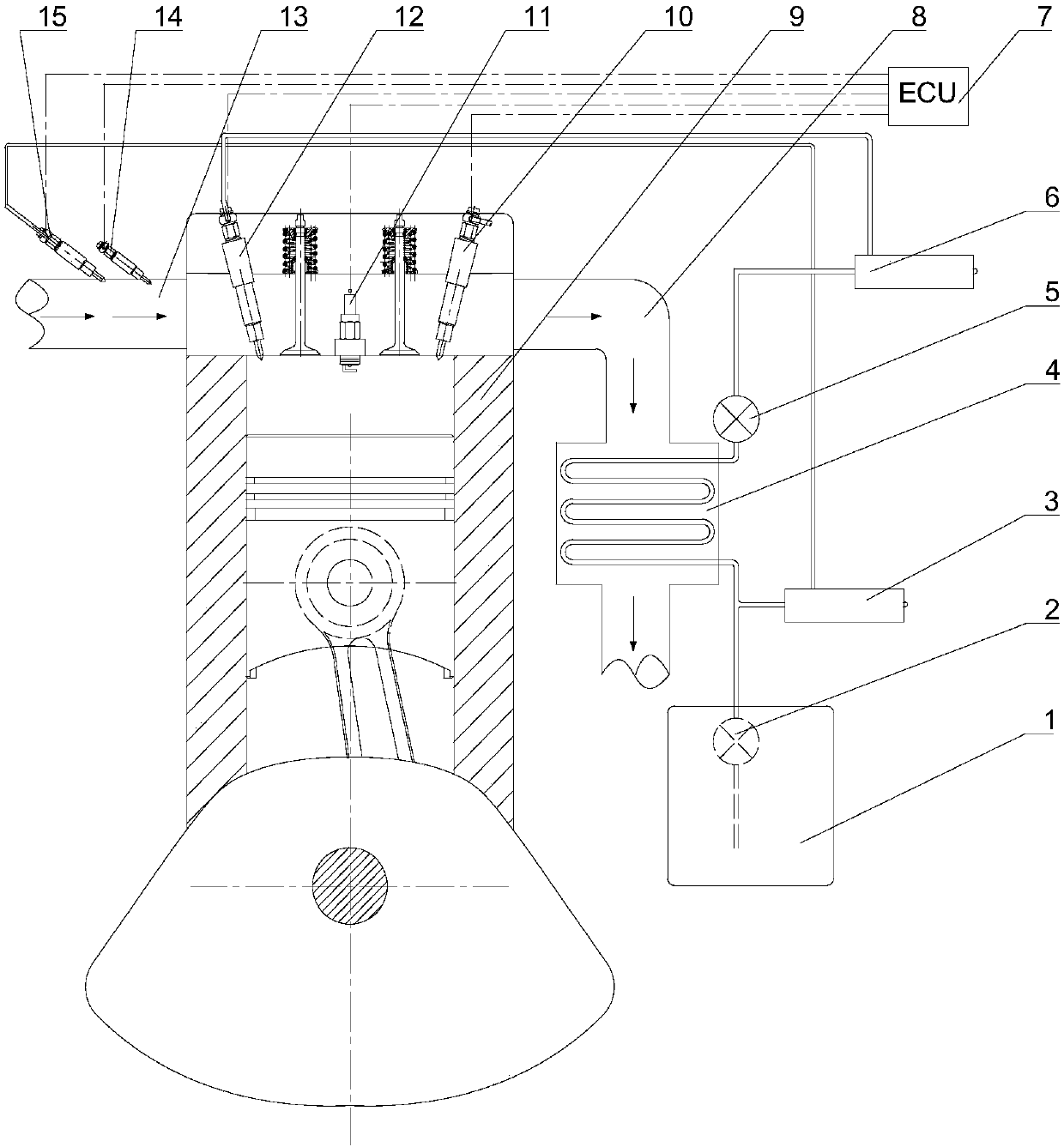

[0033] Such as figure 1 As shown, a natural gas engine structure with cold water outside the cylinder and hot water in the cylinder mixed with double injection, the structure includes a natural gas engine body 9, an intake manifold 13 and an exhaust manifold 8 arranged on the natural gas engine body 9, a natural gas injection device, a spark plug 11 arranged in the natural gas engine body 9, an in-cylinder sprinkler 12 arranged in the natural gas engine body 9, a high-pressure water pump unit communicated with the in-cylinder sprinkler 12, arranged in the intake manifold 13 The water sprayer 15 outside the cylinder, the low-pressure water pump unit connected with the water sprayer 15 outside the cylinder, the heat exchanger 4 arranged between the low-pressure water pump unit and the high-pressure water pump unit, respectively connected with the natural gas injector, the spark plug 11, the in-cylinder The electronic controller 7 electrically connected to the water sprayer 12, t...

Embodiment 2

[0041] In this embodiment, the natural gas injector is an in-cylinder natural gas injector 10 arranged in the body 9 of the natural gas engine. All the other are with embodiment 1.

Embodiment 3

[0043] In this embodiment, the natural gas injector is an out-of-cylinder natural gas injector 14 arranged on the intake manifold 13 .

[0044] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com