Quenching type methanation process with heat removing internally

A methanation and cold-shock technology, which is applied in the methanation process field, can solve the problems of coke oven gas not being used effectively, environmental pollution, energy waste, etc., and achieve the effect of improving service life, reducing device cost, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

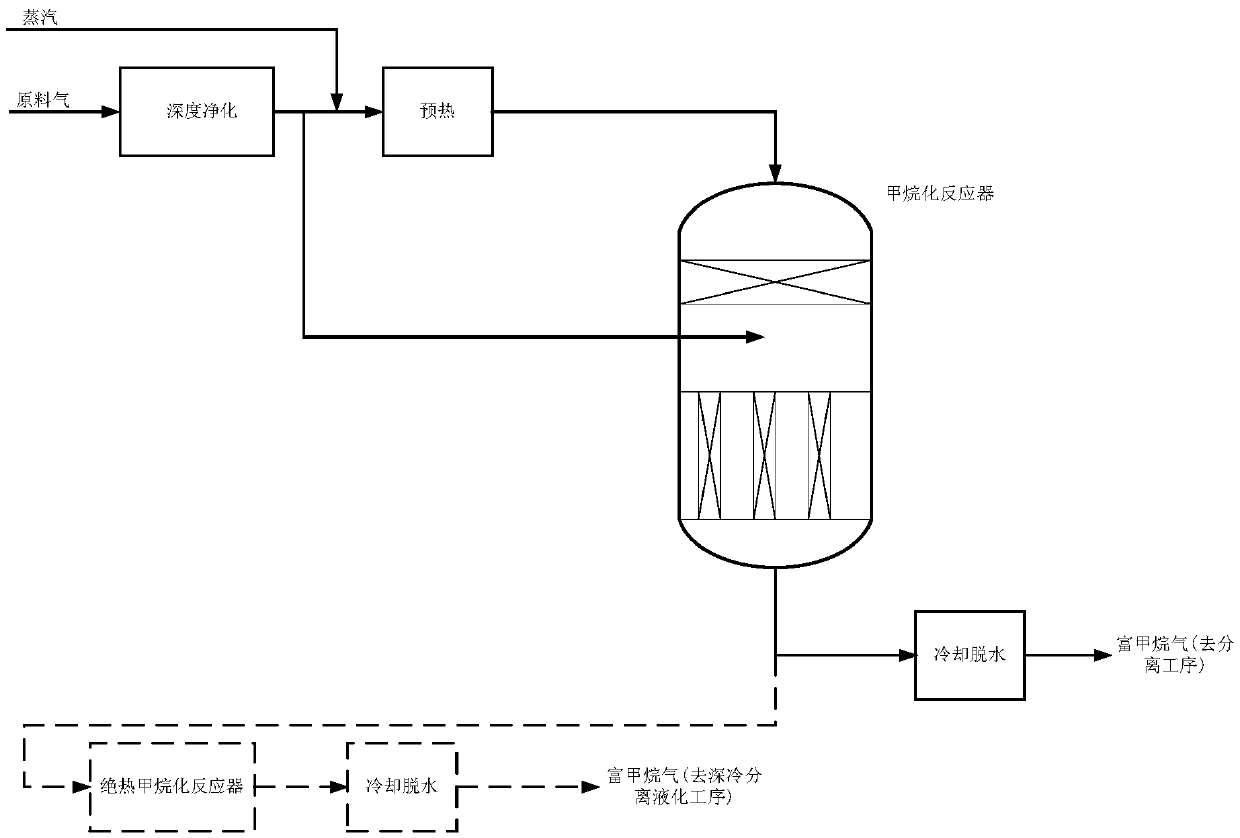

[0025] according to figure 1 As shown in the process flow, the dry base flow rate of raw gas is 1000 kmol / h, the total sulfur after deep purification is 0.015 ppm, the pressure is 1.0 MPa, and the temperature is 250 °C. The composition (mole fraction, dry basis) of the raw material gas after deep purification is H 2 58.2%, CO 8.3%, CO 2 2.7%, CH 4 24.2%, N2 4.6%, C 2 h 6 2%. The raw material gas is divided into two parts, wherein, the raw material gas volumes of the first part and the second part are 3000 kmol / h and 7000 kmol / h respectively, and the flow rate of water vapor is 4500 kmol / h. The mixed gas of raw material gas and steam is preheated to 250°C and enters the upper part of the methanation reactor, and the outlet temperature of the fixed bed is 453°C. The second part of the raw material gas is mixed with high-temperature methane-enriched gas for cooling shock, and the temperature of the mixed gas after cooling is 355°C, CO+CO 2 The mole fraction (wet basis) in ...

Embodiment 2

[0027] according to figure 1 As shown in the process flow, the dry base flow rate of raw gas is 10000 kmol / h, the total sulfur after deep purification is 0.02 ppm, the pressure is 1.5 MPa, and the temperature is 250 °C. The composition (mole fraction, dry basis) of the raw material gas after deep purification is H 2 58.2%, CO 8.3%, CO 2 2.7%, CH4 Accounting for 24.2%, N 2 4.6%, C 2 h 6 2%. Divide the raw material gas into two parts, wherein the raw gas volumes of the first part and the second part are 6000 kmol / h and 4000 kmol / h respectively, and the flow rate of water vapor is 1800 kmol / h. The mixed gas of raw material gas and steam is preheated to 250°C and enters the upper part of the methanation reactor, and the outlet temperature of the fixed bed is 602°C. The second part of the raw material gas is mixed with high-temperature methane-enriched gas for cooling shock, and the temperature of the mixed gas after cooling is 486°C, CO+CO 2 The mole fraction (wet basis) in...

Embodiment 3

[0029] according to figure 1 As shown in the process flow, the dry base flow rate of raw gas is 10000 kmol / h, the total sulfur after deep purification is 0.01 ppm, the pressure is 3.0 MPa, and the temperature is 150 °C. The composition (mole fraction, dry basis) of the feed gas after deep purification is 58.2% for H2, 8.3% for CO, 2.7% for CO2, 24.2% for CH4, 4.6% for N2, and 2% for C2H6. The raw material gas is divided into two parts, and the raw material gas volumes of the first part and the second part are 5000 kmol / h and 5000 kmol / h respectively. The flow rate of steam is 2000 kmol / h. The mixed gas of raw material gas and steam is preheated to 300°C and enters the upper part of the methanation reactor, and the outlet temperature of the fixed bed is 627°C. The second part of the raw material gas is mixed with high-temperature methane-enriched gas for cooling shock, and the temperature of the mixed gas after cooling is 436°C, CO+CO 2 The mole fraction (wet basis) in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com