Extrusion forming device for curing agent coating production

A technology of extrusion molding and curing agent, applied in grain processing and other directions, can solve the problems of low cooling efficiency of products, premature cooling of raw materials, affecting product quality, etc., to improve product quality and production efficiency, improve operation convenience, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

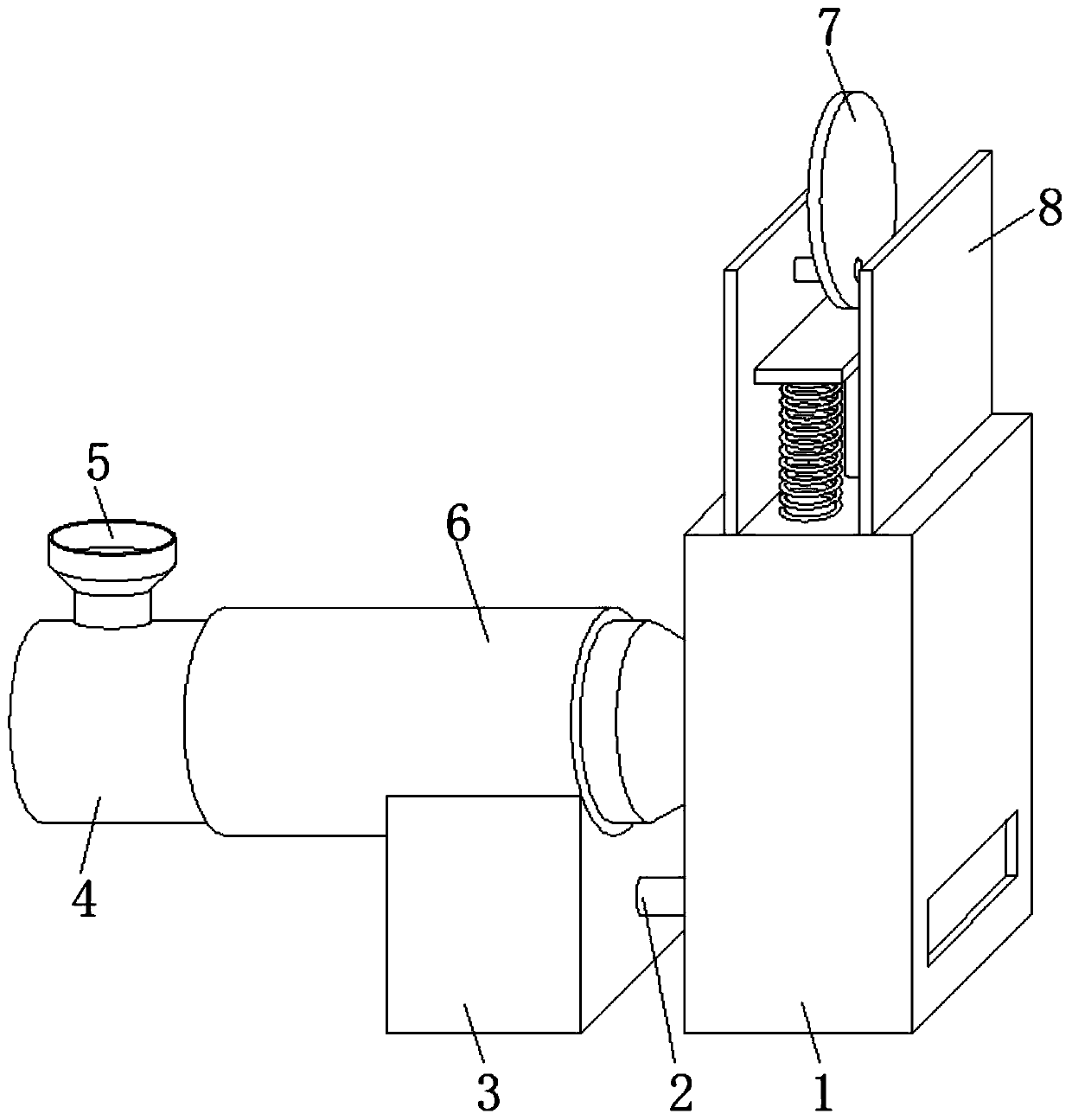

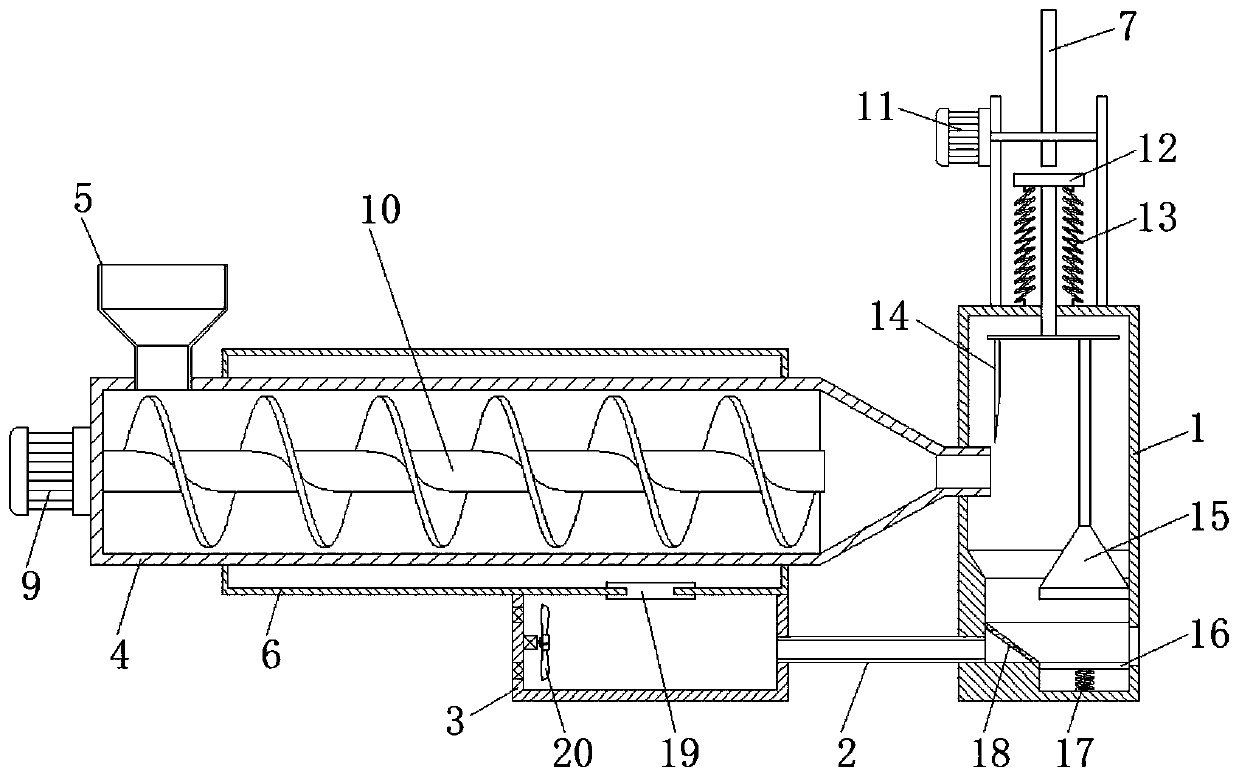

[0029] refer to Figure 1-2 , a kind of extrusion molding device for the production of curing agent paint, comprising a molding box 1, a cold air box 3 and an extrusion tube 4, an installation opening is opened in the middle of one side of the outer wall of the molding box 1, and the extrusion tube 4 is fixed to the installation by screws The inner wall of the mouth, the bottom of the outer wall on the opposite side of the air-conditioning box 3 and the molding box 1 are all provided with air supply pipe jacks, and the inner walls of the two air supply pipe jacks are inserted with the same air supply pipe 2 and extrusion pipe 4 The outer wall of the water bath box 6 is welded with a water bath box 6, and the water bath box 6 is fixed on the air-conditioner box 3 by screws. The side inner wall is fixed with a fan 20 by screws, the inner wall of the extrusion pipe 4 is provided with an extrusion mechanism, and the inner wall of the molding box 1 is provided with a pressing mecha...

Embodiment 2

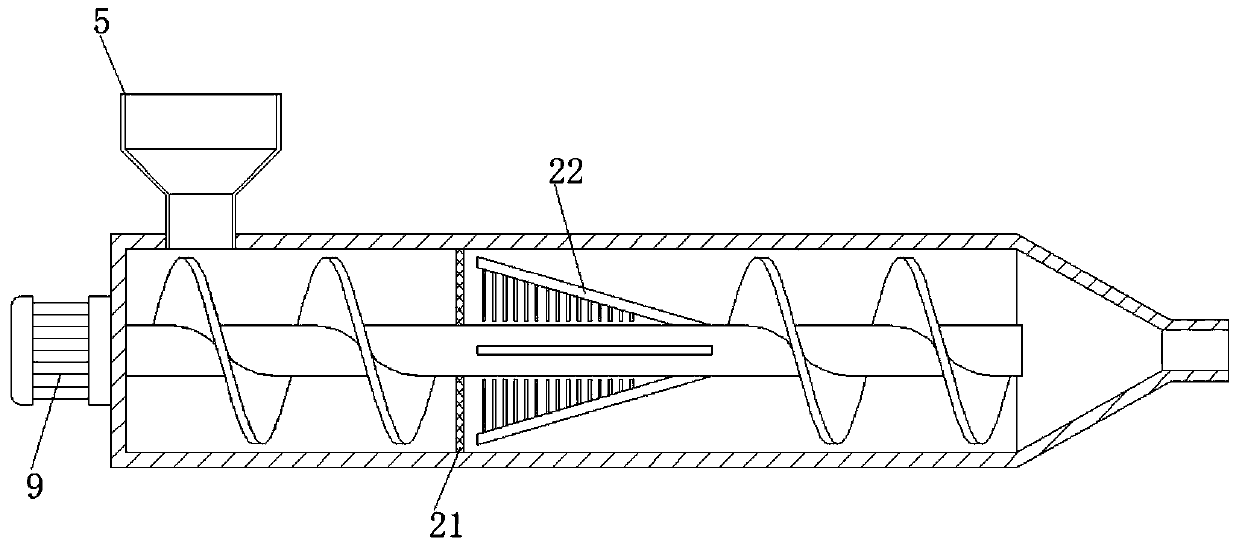

[0039] refer to image 3 , a kind of extrusion molding device for the production of curing agent paint, the outer wall of the conveying shaft 10 is fixed with at least three stirring rods 22 uniformly distributed by screws, and the outer wall of the stirring rods 22 is welded with comb teeth, the stirring rods 22 are arranged obliquely, stirring The distance between the rod 22 and the conveying shaft 10 gradually increases toward the direction approaching the hopper 5 .

[0040] Wherein, the inner wall of the extrusion pipe 4 is fixed with a dispersing plate 21 by screws, and the dispersing plate 21 is connected to the outer wall of the conveying shaft 10 through a bearing, and the dispersing plate 21 is a mesh-like structure.

[0041] Working principle: While the conveying shaft 10 is conveying the raw materials, the dispersing plate 21 breaks up the agglomerated raw materials, and at the same time the stirring rod 22 mixes the raw materials to improve the uniformity of raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com