Ultrapure purification process and ultrapure purification system for nitrogen, argon and oxygen

An argon and oxygen technology, applied in the field of purification system, can solve the problems of prolonging the regeneration cycle of the adsorption process, consuming the adsorption capacity of the adsorption process, and shortening the regeneration cycle of the adsorption process, so as to reduce operating costs, avoid uneven flow rates, and reduce system costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

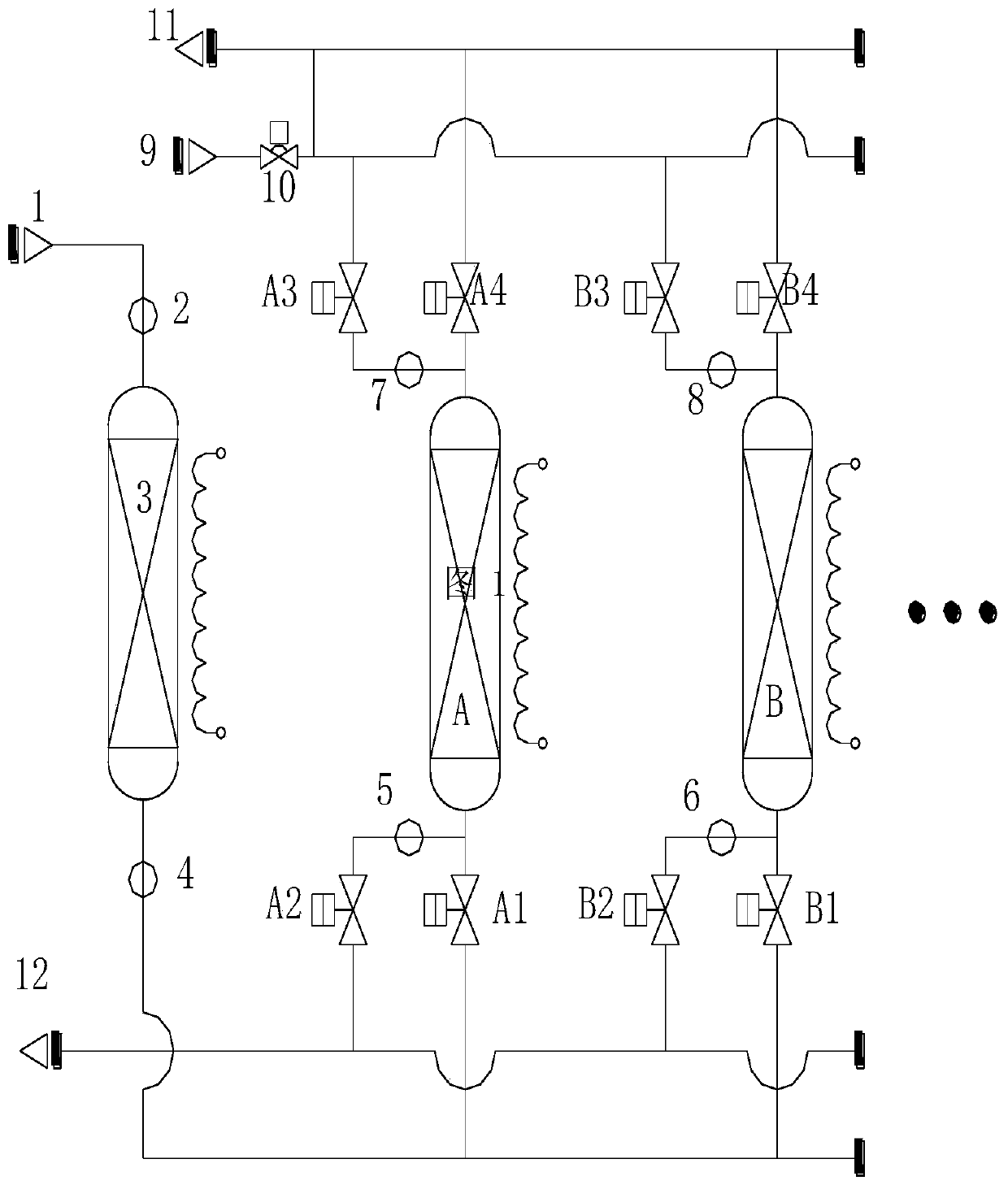

[0030] Combine below figure 1 The present invention is described further:

[0031] An ultra-pure purification system for nitrogen, argon, and oxygen, including a catalytic oxidation system, an adsorption system, and a control system; the catalytic oxidation process includes a catalytic reactor 3, a catalytic heater, a thermal insulation heating jacket, a catalytic cooler 4, and a heat exchange The device and the oxidation catalyst packed inside. The adsorption system includes two adsorption reactors, one for standby and one for use, corresponding valves, corresponding pipelines, regeneration gas heater, regeneration gas cooler and control system; the adsorption reactor is filled with deoxidizer; the catalytic system and The raw material gas inlet is connected, the catalytic system outlet is connected with the raw material gas inlet of the adsorption system, and the adsorption system outlet is connected with the product gas outlet. The inlet of the adsorption reactor is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com