Flange plate heat exchange type automobile tail gas power generation device

A technology of automobile exhaust and power generation device, which is applied in the direction of exhaust device, muffler device, generator/motor, etc. It can solve the problems of high exhaust gas temperature, low power generation efficiency, convection of external low temperature air, etc., and achieve high heat transfer efficiency , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

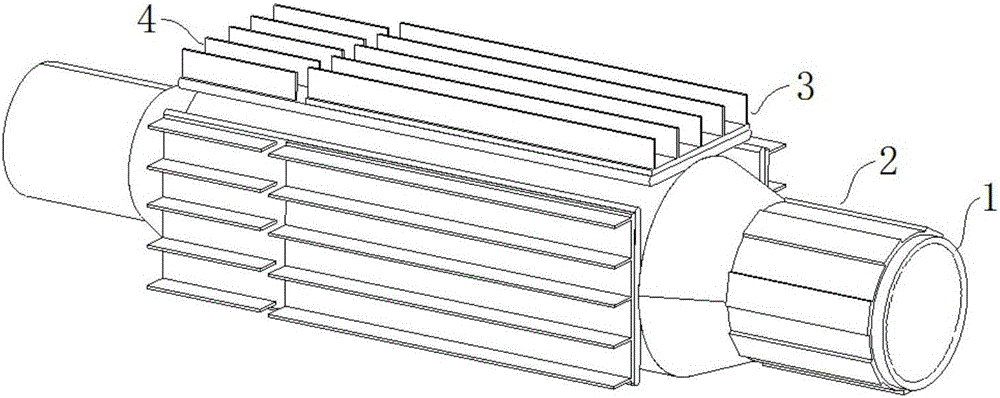

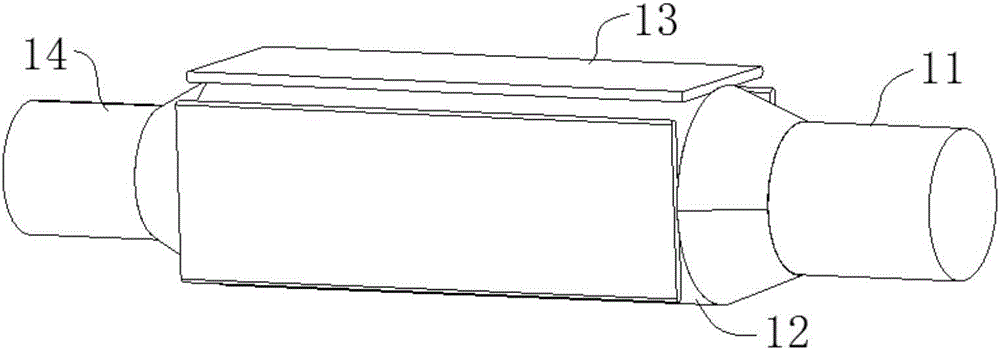

[0038] combine figure 1 , figure 2 , a wing plate heat exchange type automobile exhaust power generation device of the present embodiment comprises an exhaust pipe 1, the exhaust pipe 1 is divided into a high temperature section 11, a power generation and cooling section 12 and an exhaust section 14, a high temperature section 11 and an exhaust section 14 It is connected with the power generation and heat dissipation section 12 through a tapered transition pipe, which has a certain noise reduction effect. The exhaust pipe 1 can also be a pipeline of equal diameter, and the segmentation of the exhaust pipe 1 is only for easier distinction in function, and has nothing to do with the specific structure. The temperature of the high-temperature section is only higher than that of the power generation and cooling section 12 and the exhaust section 14, and there is no special limitation on the temperature. The outer periphery of the high-temperature section 11 is provided with a f...

Embodiment 2

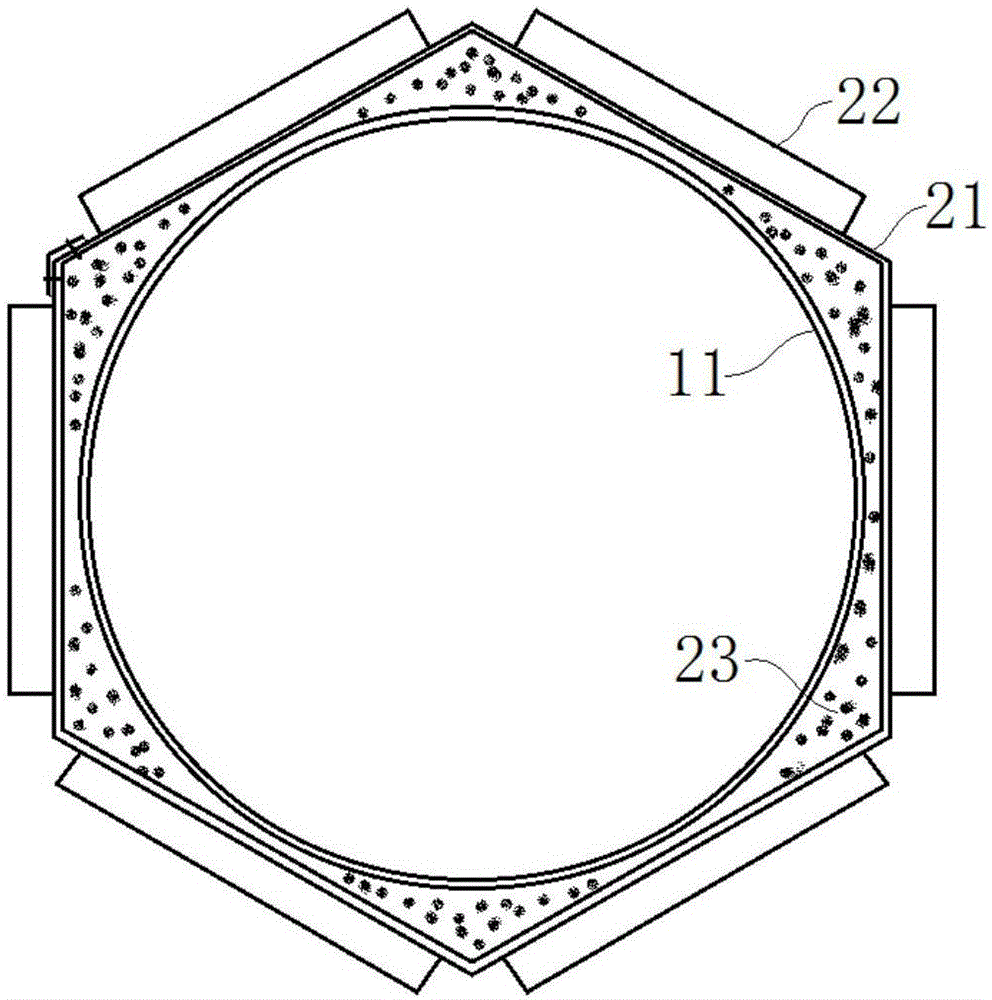

[0046] combine image 3 , a wing plate heat exchange type automobile exhaust power generation device of this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that the first power generation module 2 of this embodiment includes an annular base plate 21 and a first thermoelectric power generation Component 22 , the annular base plate 21 is a polygonal structure after closing, the first thermoelectric power generation component 22 is fixed on the outer surface of each side of the annular base plate 21 , and the hot end of the first thermoelectric power generation component 22 is in contact with the annular base plate 21 . Wrapping the annular base plate 21 on the outer surface of the high-temperature section of the exhaust pipe 1 , the internal heat is not easy to dissipate while generating power, which helps to provide a higher internal temperature for the second thermoelectric power generation component 33 .

[0047] Since the annular subst...

Embodiment 3

[0049] A kind of wing plate heat exchange type automobile exhaust power generation device of this embodiment, its basic structure is the same as embodiment 1, and its difference is: this embodiment is also provided with cooling module 4 on wing plate 13, and described cooling module 4 and the second power generation module 3 are arranged along the length direction of the wing plate 13, and the second power generation module 3 is located near the end of the high temperature section 11.

[0050] Furthermore, in order to improve the power generation efficiency at the high-temperature end, the high-temperature section 11 of the exhaust pipe can be set as a polygon, and the thermoelectric power generation sheet can be directly attached to the outer wall of the exhaust pipe, and the contact area is increased. like Figure 4 As shown in , the high-temperature section 11 is set as a regular hexagon, the annular base plate 21 is fastened to the outside of the exhaust pipe, and a heat-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com