Structure of fan devices for leading out wires

a technology of fan device and lead wire, which is applied in the direction of positive displacement liquid engine, piston pump, instruments, etc., can solve the problems of small windage loss and contact between wires and impellers, and achieve the effect of minimizing windage loss and small windage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

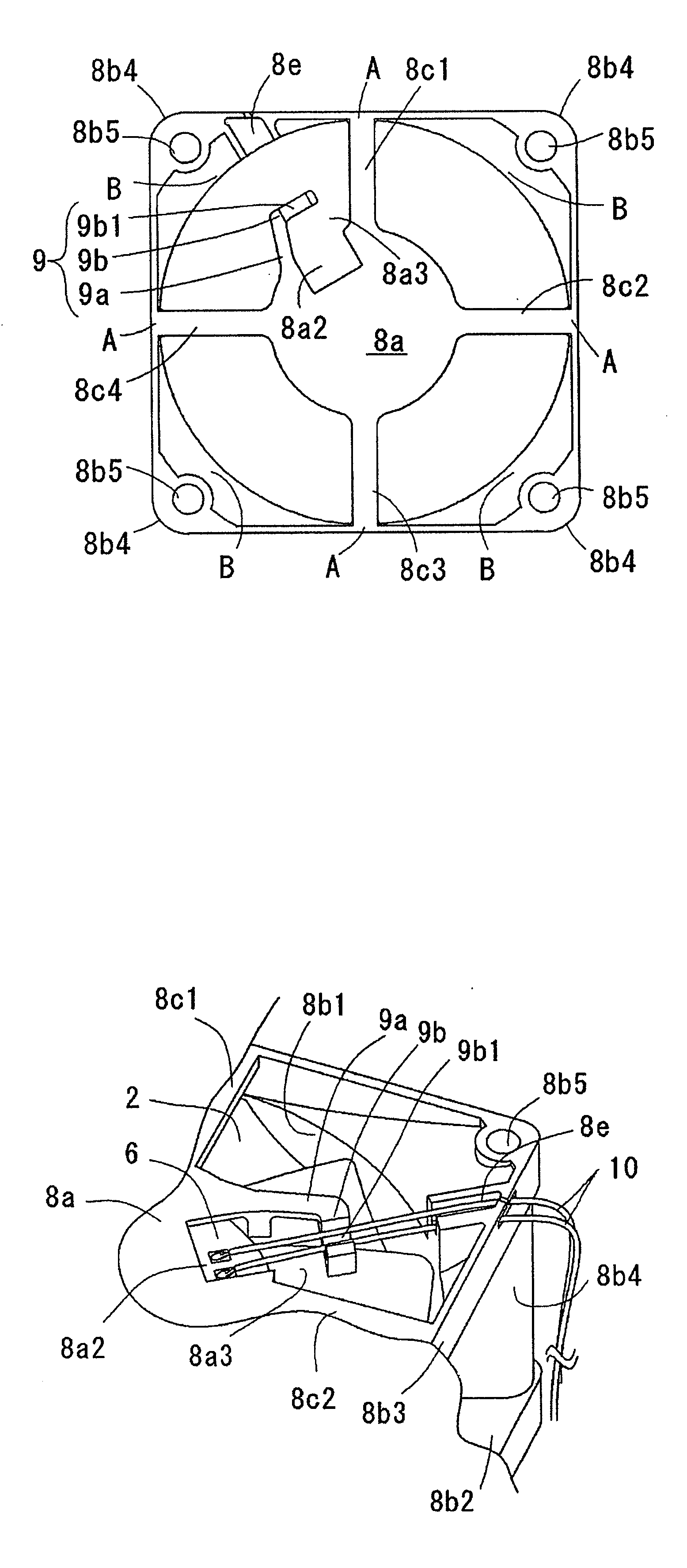

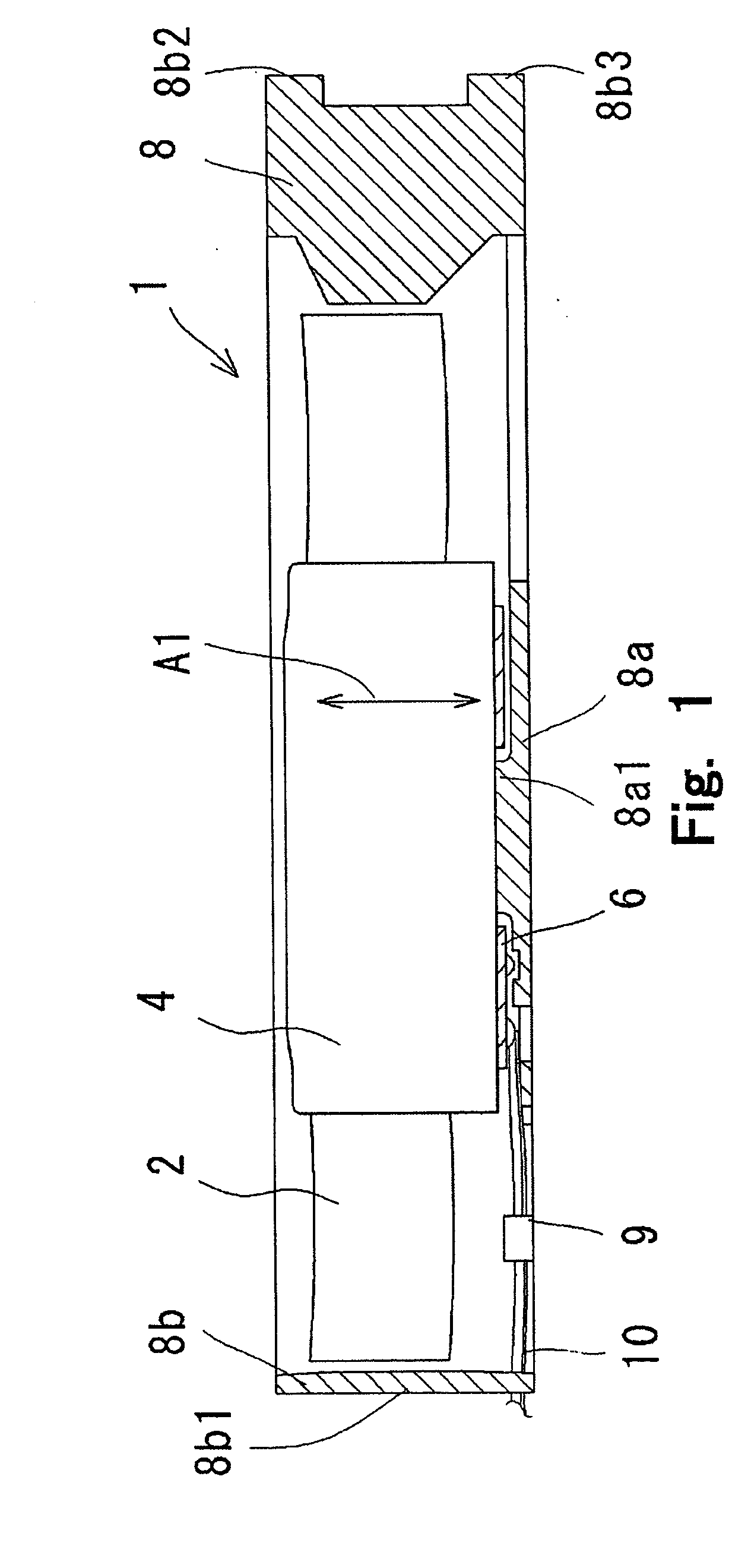

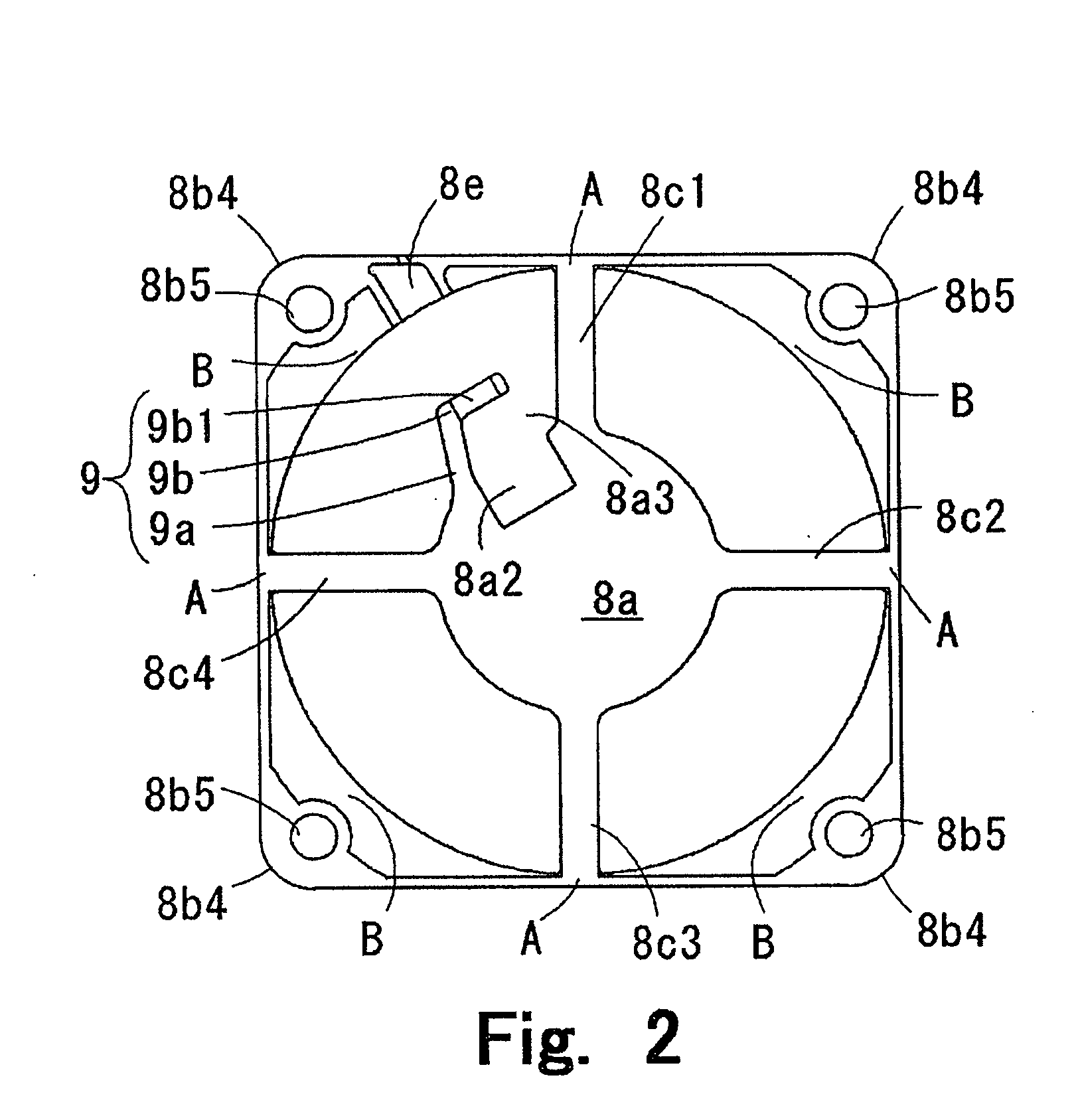

Image

Examples

first embodiment

[0046] In the fan device according to this embodiment, the lead wire is led out not through the support beams 8c1-8c4 but through the space between the same and the motor support portion 8a. Furthermore, the fan device of this embodiment has the same feature as the fan device of the first embodiment in that the lead wire retaining portion 29 is positioned at the motor support portion 8a side. Particularly, as the lead wire retaining recess 29b is supported by the two arm portions 29a1 and 29a2, the lead wire retaining portion 29 has a high rigidity and is fixed to the motor support portion 8a securely. Thus, the housing 8 itself or the completed fan device is resistant to be broken even if a certain obstacle comes into collision with the lead wire retaining portion 29.

[0047] Next, a fan device according to a third embodiment of the present invention will be described mainly about the difference from the first embodiment with reference to FIG. 5. FIG. 5 shows a bottom view of the hou...

third embodiment

[0052] In the fan device according to this embodiment, the lead wire is led out not through the support beams 8c1-8c4 but through the space between the same and the motor support portion 8a. The fan device of this embodiment has the same feature as the fan device of the third embodiment in that the lead wire retaining portion 49 is positioned at the fan outer frame portion side. However, especially the two arm portions 49a1 and 49a2 support the lead wire retaining recess 49b, so the lead wire retaining portion 49 has a high rigidity and is fixed to the motor support portion 8a securely. Thus, the housing 8 itself or the completed fan device is resistant to be broken even if a certain obstacle comes into collision with the lead wire retaining portion 49.

[0053] Though preferred embodiments for implementing the fan device according to the present invention are described above, the present invention is not limited to these embodiments and various modifications is possible in the scope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com