Stock receiving device for air hoister

A technology of material receiving device and hoist, which is applied in the direction of conveyor, transportation and packaging, and conveying bulk materials, etc. It can solve the problems that the feeding pipe cannot be stably fixed, can only be hoisted with iron wire, and the unloader is displaced, etc., to achieve The effect of stable center of gravity, energy saving, and wind pressure resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

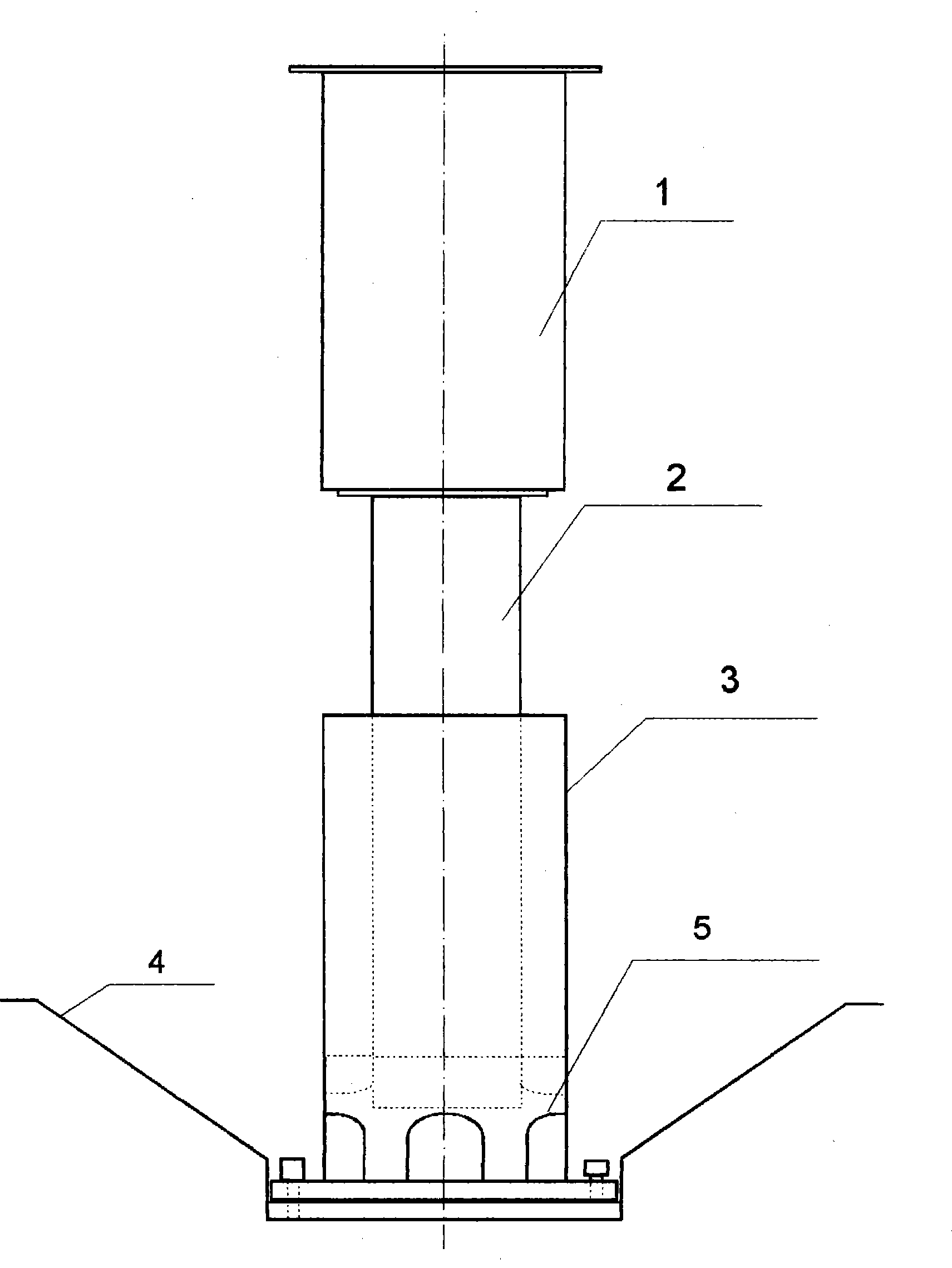

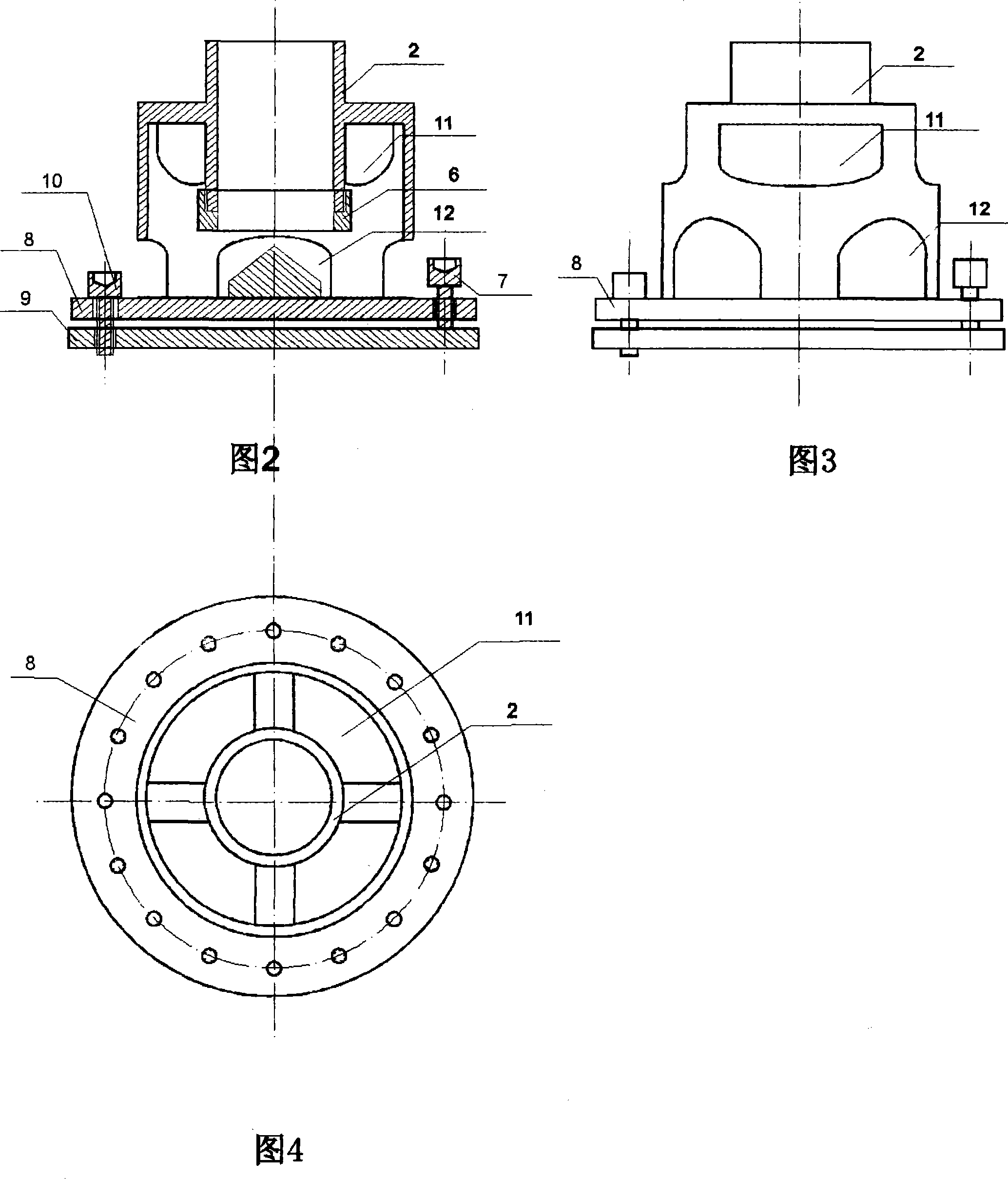

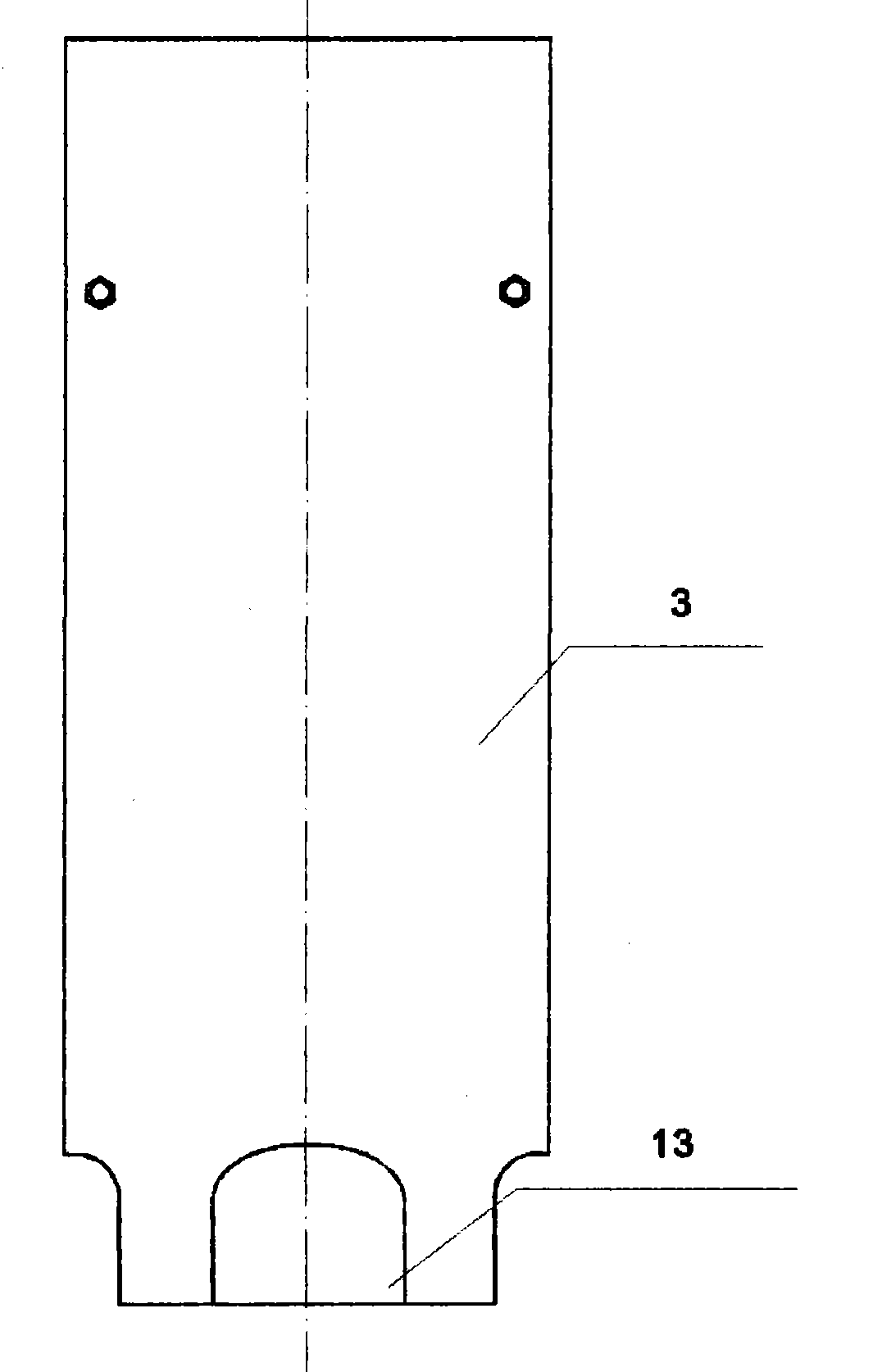

[0014] like figure 1 , Figure 2, Figure 3, Figure 4, Figure 5 and Image 6 Shown: the material receiving device of the air lifter of the present invention mainly includes a feed pipe and an outer casing, and is characterized in that: the feed pipe is composed of the buffer pipe 1 of the upper section and the acceleration pipe 2 of the lower section, and the buffer pipe 1 The upper end communicates with the unloader of the hoist, and a feeding seat 5 is arranged below the acceleration tube 2. The upper part of the feeding seat 5 is provided with several air inlets 11, and the lower part has several feeding ports 12. The feeding seat 5 There is an adjusting plate 8 below the bottom, and the adjusting plate 8 is fixed on the ground fixed plate 9 fixed in the receiving plate 4 with cement by locking the adjusting screw 10, and the outer casing 3 is set on the feeding seat of the lower section of the accelerating tube 2 5, there is a gap between the inner wall of the outer casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com