Filter element cleaning, drying and sealing device for maintenance-free electrostatic dust collection filter box

An electrostatic precipitator component and electrostatic precipitator technology, applied in combined devices, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of residual water stains that cannot be dried in time, unreasonable sealing design of dust filter elements, and low cleaning efficiency, etc., to achieve Simple structure, small wind resistance loss and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

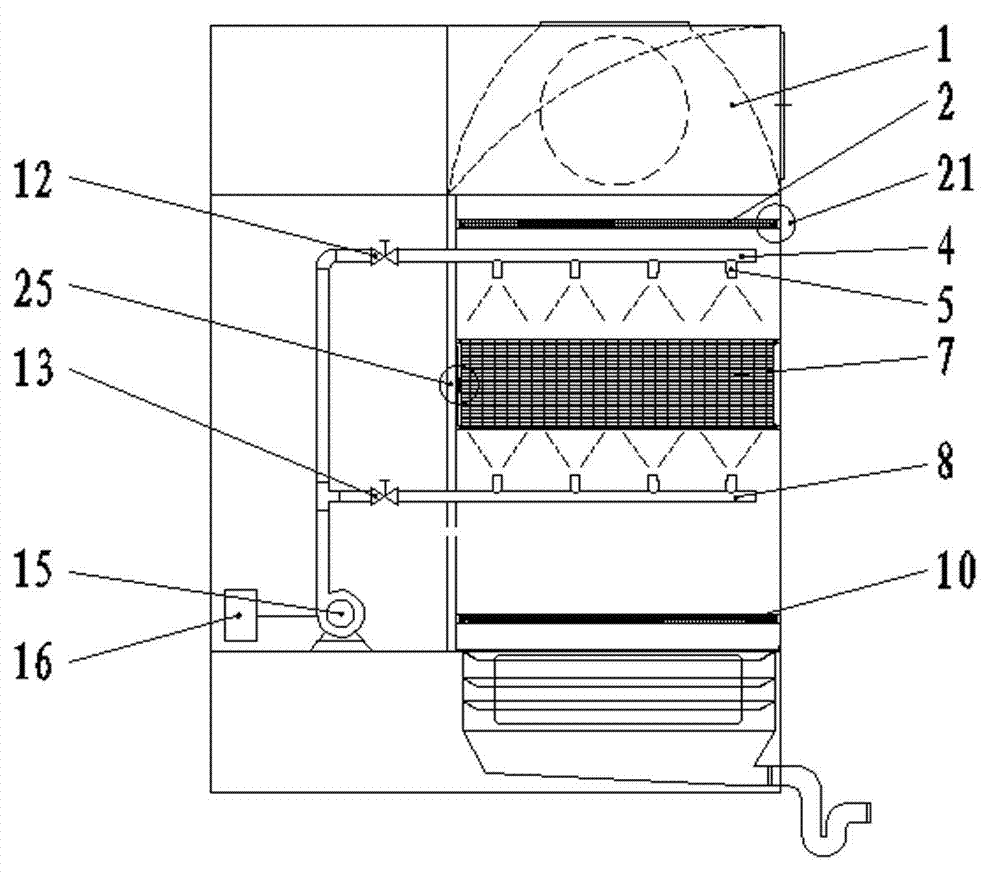

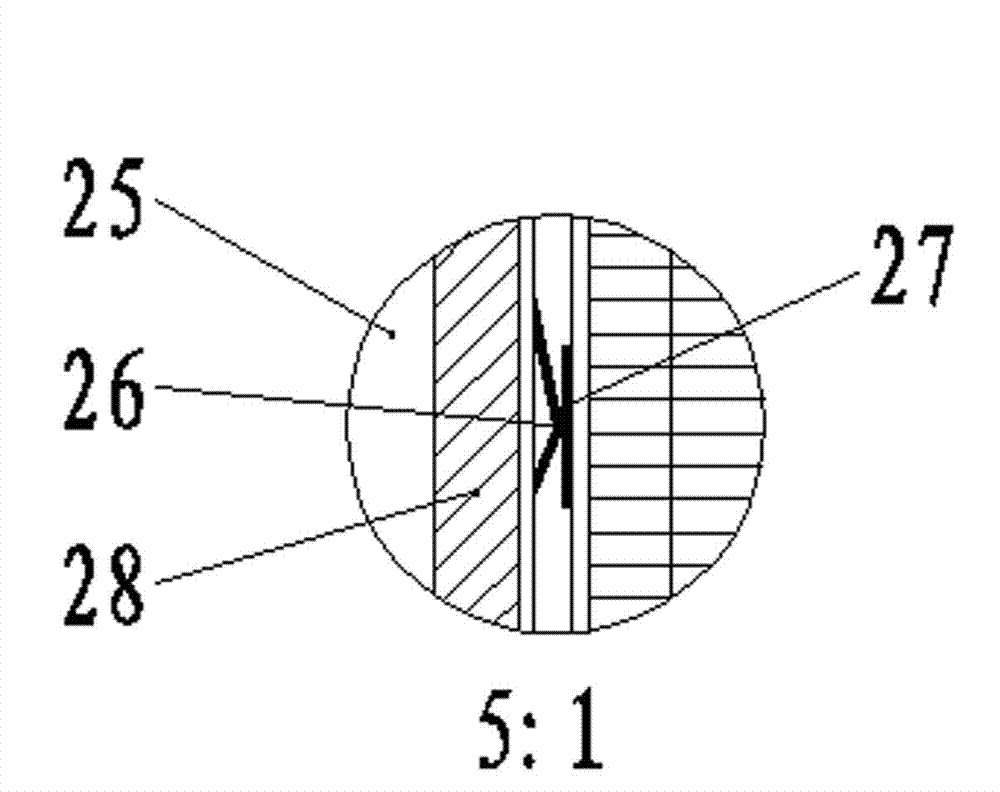

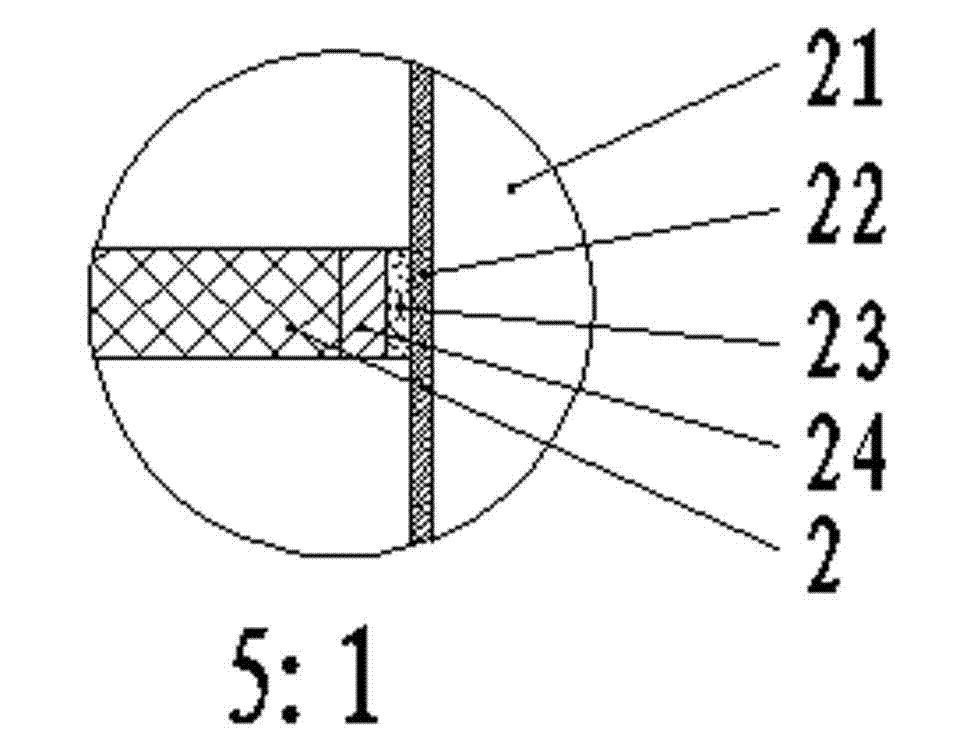

[0030] refer to figure 1 , Figure 2-2 , image 3 , Figure 4 , the present embodiment includes an upper spray pipe 4, a lower spray pipe 8, an end sealing structure and a side sealing structure, and the upper spray pipe 4 is arranged between the electrostatic precipitator assembly 7 and the ozone separation net 2 in the filter box, The lower part of the upper spray pipe 4 is provided with a nozzle 5, the lower spray pipe 8 is arranged between the electrostatic precipitator assembly 7 and the primary filter 10 in the filter box, the upper part of the lower spray pipe 8 is provided with a nozzle, and the upper spray pipe 4 passes through The first solenoid valve 12 is connected to the pump 15, the lower spray pipe 8 is connected to the pump 15 through the second solenoid valve 13, and the pump 15 is connected to the main controller 16; the upper spray pipe 4 side is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com