Fully automatic electrostatic dust removal filter box with sealing structure

A technology of electrostatic dust removal and sealing structure, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc. It can solve the problems of unreasonable design of the sealing method around the dust removal parts, low dust removal efficiency of the whole machine, and failure of electrical contact parts. Simple structure, small wind resistance loss and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

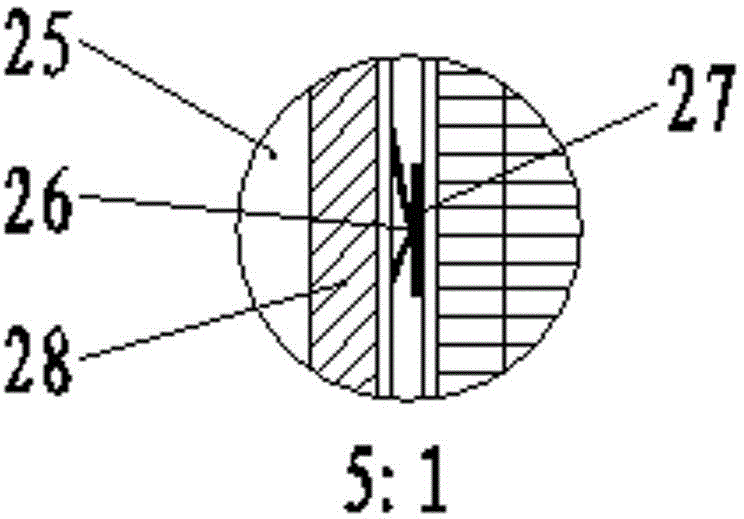

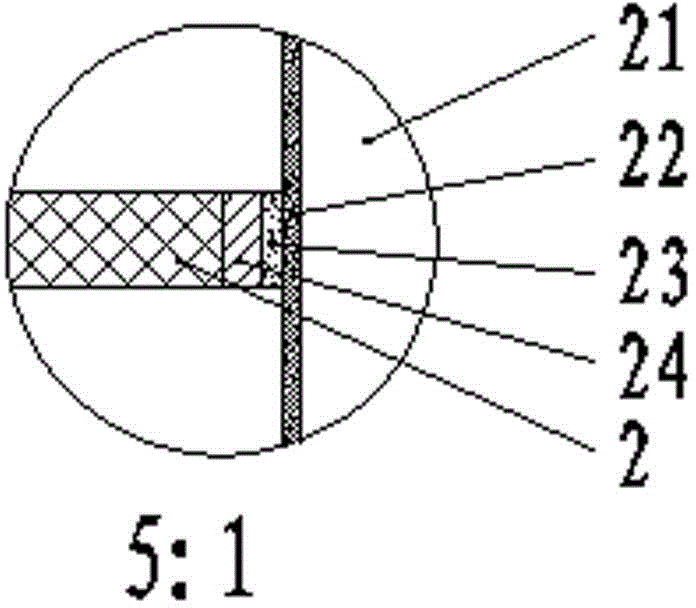

[0028] Reference Figure 2-2 , Figure 4 This embodiment includes an end sealing structure and a side sealing structure. The end sealing structure includes a compression sealing strip 24. One side of the compression sealing strip 24 is provided with adhesive 23. The side sealing structure includes a strip The sealing strip 17 is provided with a fixing component 20 at the end of the belt-shaped sealing strip 17.

[0029] The compression sealing strip may be a hollow cross-section sealing strip or a solid cross-section sealing strip, the compression sealing strip is a non-absorbent sealing strip, and the long-term temperature tolerance of the compression sealing strip is -20 degrees to 60 degrees.

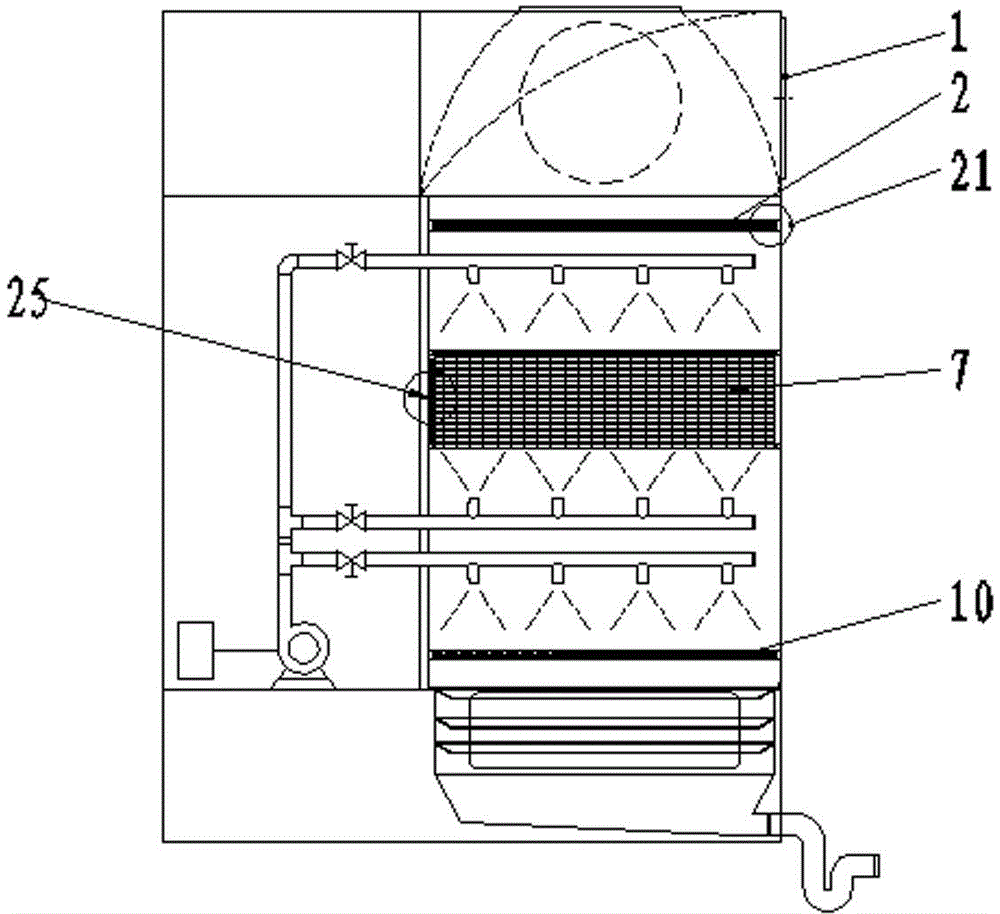

[0030] The automatic electrostatic dust removal filter box includes a box body 1, one end of the box body 1 is provided with an end face side door 22, the other end of the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com