Armature assembly

A pipe joint, direct technology, applied in the direction of valve device, pipe/pipe joint/pipe fitting, valve operation/release device, etc., can solve problems such as pressure loss, large resistance coefficient, differential regulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

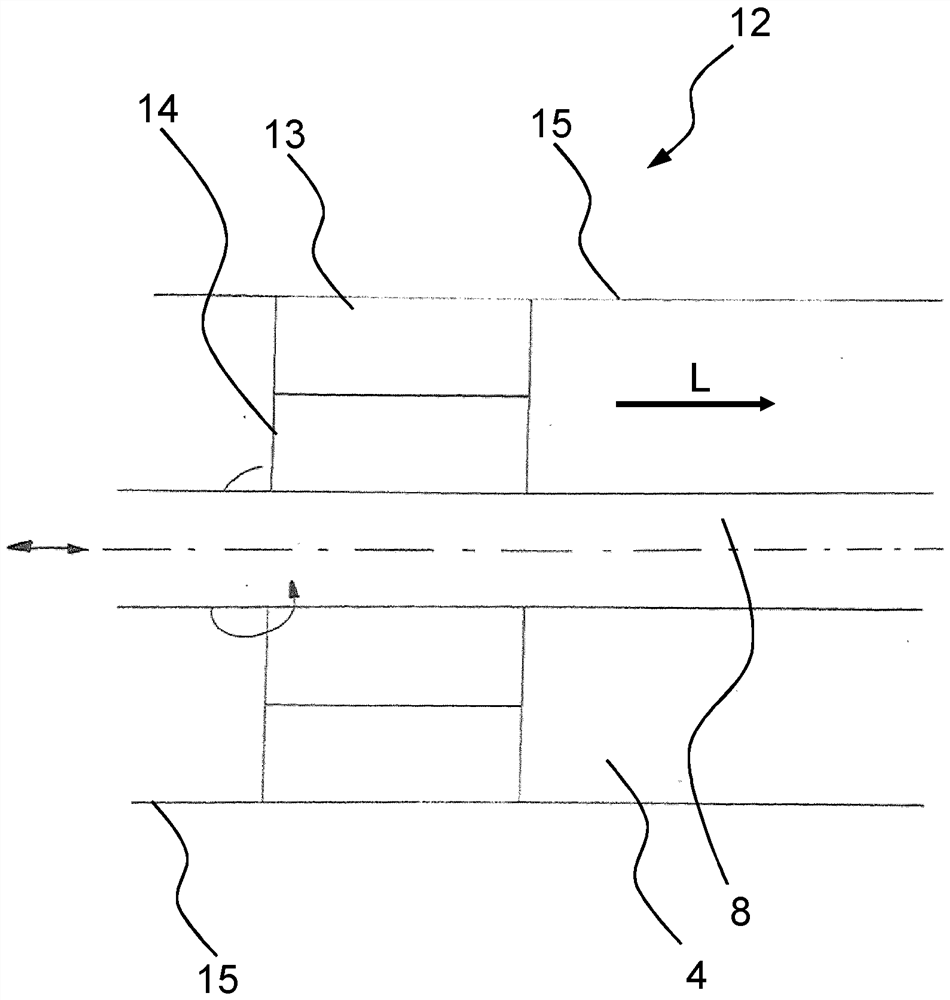

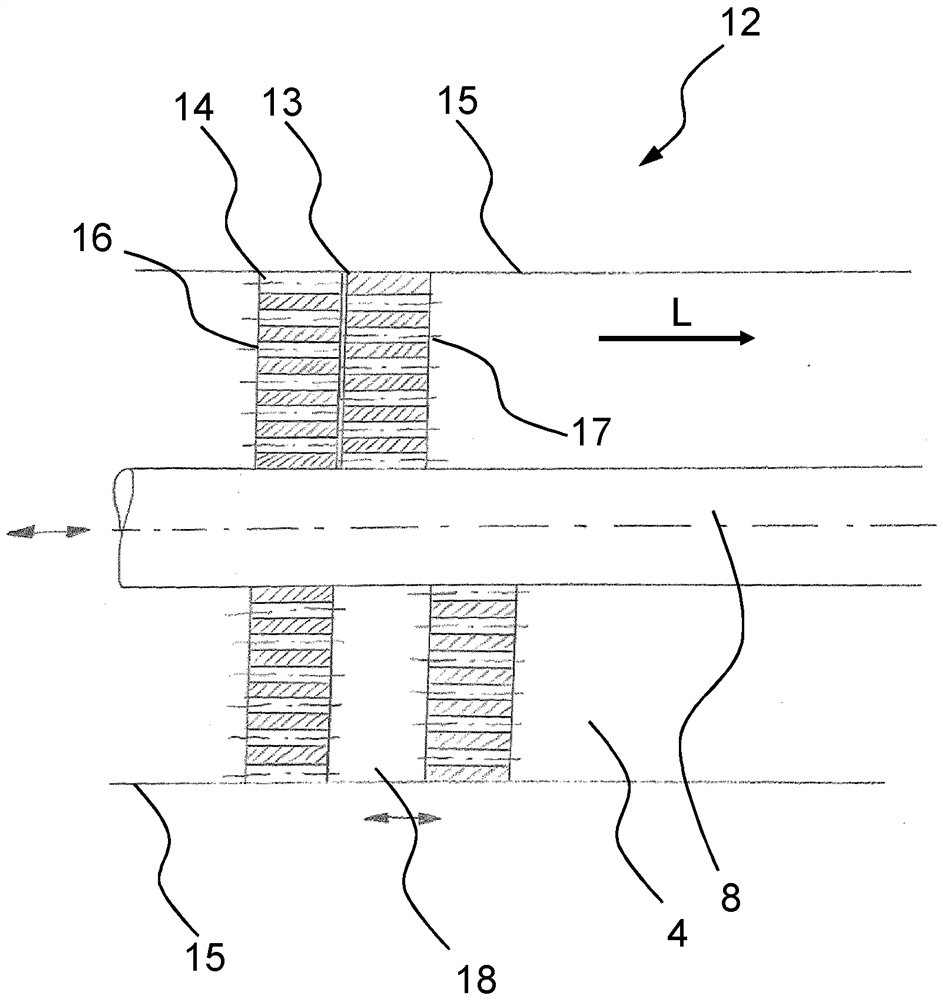

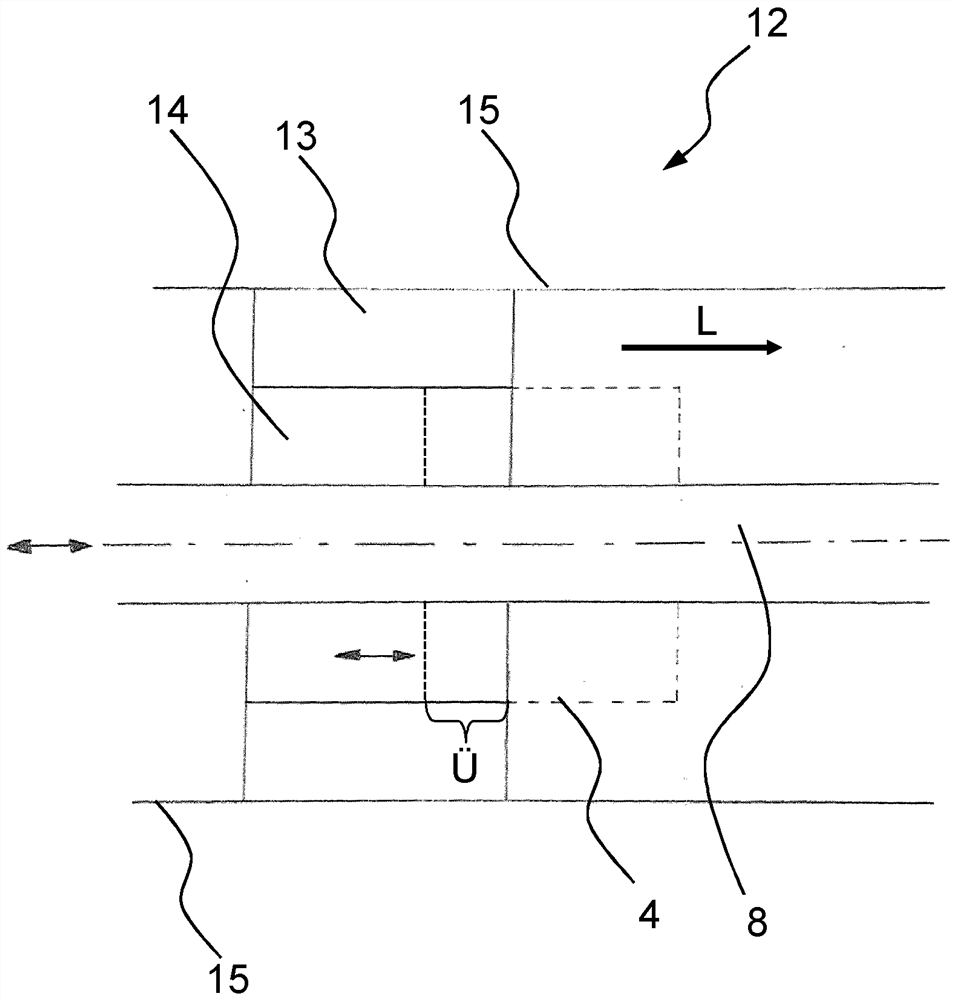

[0033] figure 1 A pipe connection arrangement according to the invention is shown. The pipe connection arrangement has a housing 1 which can be installed at both ends via flanges 9 in each case in a flow-guiding device, for example a pipe. The flange 9 has bores for receiving fastening means. This is preferably a screw connection.

[0034] A channel 4 is provided in the housing 1 , which opens into the first and the second opening 2 , 3 at the end of the housing 1 . In an operating state, the connector arrangement is operated such that the first opening 2 is configured as an inlet opening for a fluid flow and the second opening 3 is configured as an outlet opening for a fluid flow. The working medium thus flows counter to the channel direction L shown.

[0035] The channel 4 has no bends along the channel direction L. This means that the fluid flow is not deflected by the housing or that the center point of the area of the cross section of the channel 4 is arranged at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com