Surface gluing equipment for machining resistance elements

A resistance element and equipment technology, which is applied in the field of surface coating equipment for resistance element processing, and can solve problems such as low efficiency and uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

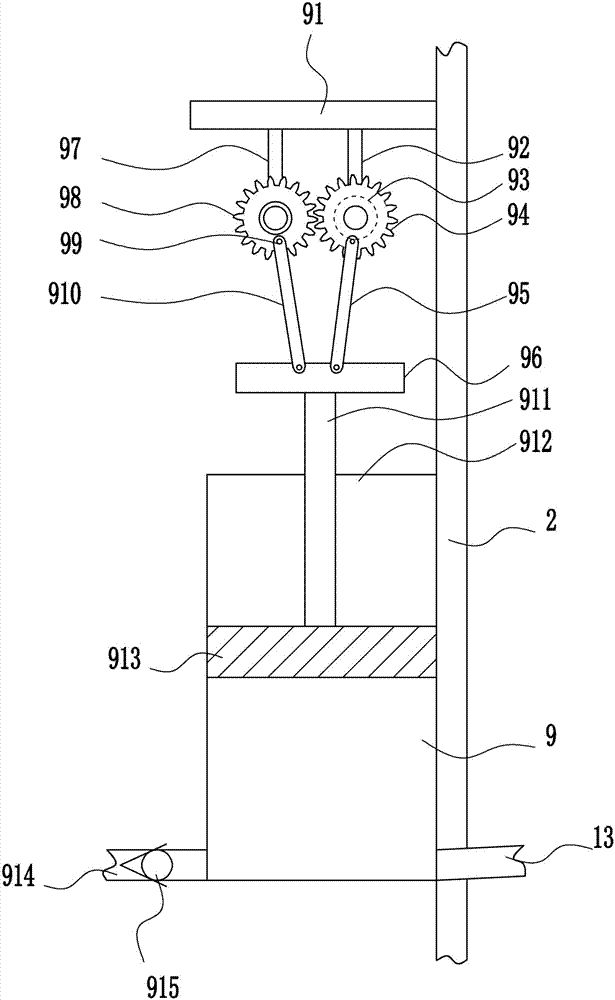

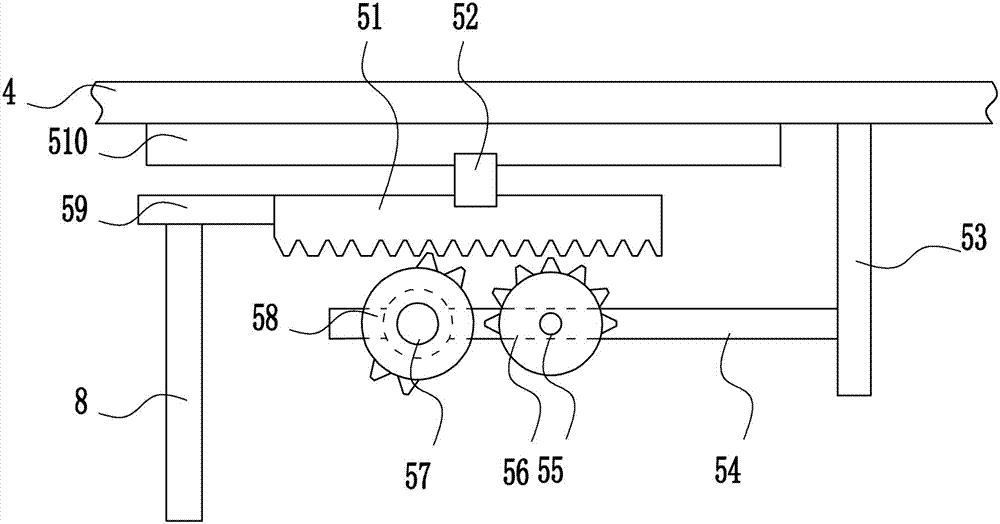

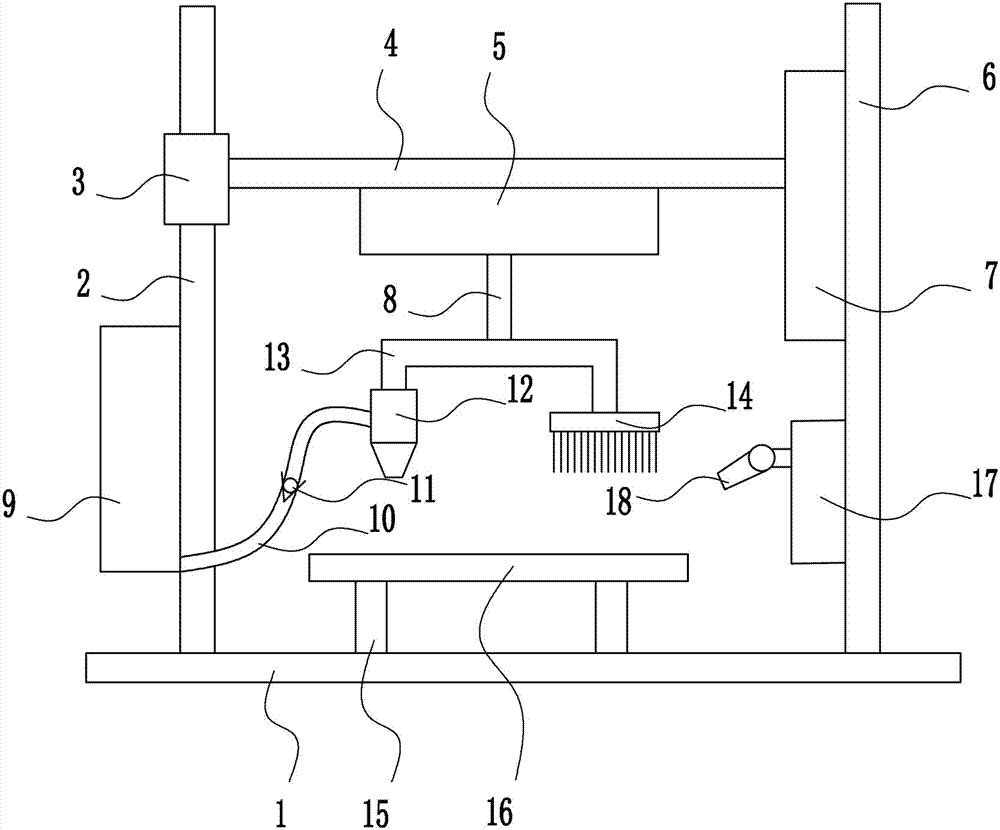

Embodiment 1

[0036] A surface coating equipment for resistance element processing, such as Figure 1-6 As shown, it includes base plate 1, first guide rod 2, first guide sleeve 3, lifting rod 4, moving device 5, right frame 6, lifting device 7, moving rod 8, glue delivery device 9, hose 10, the first A one-way valve 11, dispensing head 12, T-shaped mounting plate 13, brush 14, first support 15, placement table 16, swing device 17 and fan 18, the first guide rod 2 is welded on the left side of the bottom plate 1 top, the second A guide rod 2 is sleeved with a first guide sleeve 3, a right frame 6 is welded on the right side of the top of the bottom plate 1, a moving device 5 is arranged on the upper left side of the right frame 6, and a lifting rod 4 is connected to the left side of the moving device 5, and the lifting rod 4. The left end is connected to the right end of the first guide sleeve 3 by welding. A moving device 5 is arranged in the middle of the bottom of the lifting rod 4. The ...

Embodiment 2

[0038] A surface coating equipment for resistance element processing, such as Figure 1-6 As shown, it includes base plate 1, first guide rod 2, first guide sleeve 3, lifting rod 4, moving device 5, right frame 6, lifting device 7, moving rod 8, glue delivery device 9, hose 10, the first A one-way valve 11, dispensing head 12, T-shaped mounting plate 13, brush 14, first support 15, placement table 16, swing device 17 and fan 18, the first guide rod 2 is welded on the left side of the bottom plate 1 top, the second A guide rod 2 is sleeved with a first guide sleeve 3, a right frame 6 is welded on the right side of the top of the bottom plate 1, a moving device 5 is arranged on the upper left side of the right frame 6, and a lifting rod 4 is connected to the left side of the moving device 5, and the lifting rod 4. The left end is connected to the right end of the first guide sleeve 3 by welding. A moving device 5 is arranged in the middle of the bottom of the lifting rod 4. The ...

Embodiment 3

[0041] A surface coating equipment for resistance element processing, such as Figure 1-6As shown, it includes base plate 1, first guide rod 2, first guide sleeve 3, lifting rod 4, moving device 5, right frame 6, lifting device 7, moving rod 8, glue delivery device 9, hose 10, the first A one-way valve 11, dispensing head 12, T-shaped mounting plate 13, brush 14, first support 15, placement table 16, swing device 17 and fan 18, the first guide rod 2 is welded on the left side of the bottom plate 1 top, the second A guide rod 2 is sleeved with a first guide sleeve 3, a right frame 6 is welded on the right side of the top of the bottom plate 1, a moving device 5 is arranged on the upper left side of the right frame 6, and a lifting rod 4 is connected to the left side of the moving device 5, and the lifting rod 4. The left end is connected to the right end of the first guide sleeve 3 by welding. A moving device 5 is arranged in the middle of the bottom of the lifting rod 4. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com