Efficient cocoon drying machine capable of evenly distributing hot air

A technology of uniform dispersion and cocoon drying machine, which is applied in the field of machinery, can solve problems such as unevenness, incomplete drying of cocoons, and failure to consider cocoons, etc., to achieve the effects of improved time, ingenious structural design, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

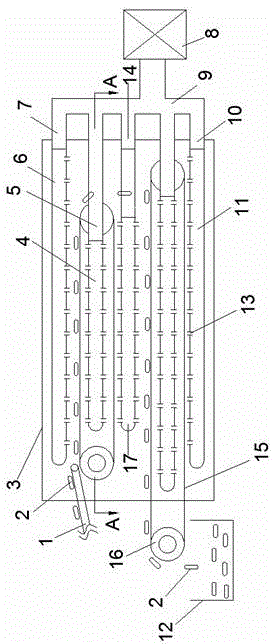

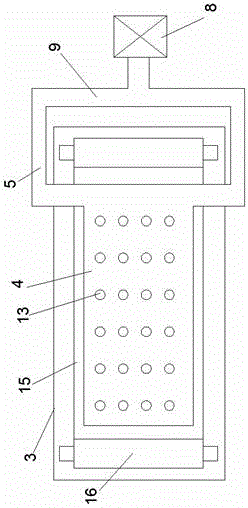

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention. It should be noted that these drawings are all simplified schematic diagrams, and only schematically illustrate the basic structure of the present invention, so they only show the configurations related to the present invention.

[0027] figure 1 It is a structural schematic diagram of the present invention, figure 2 yes figure 1 The cross-sectional view of A-A in the figure, combined with the accompanying drawings, it can be seen that the high-efficiency cocoon drying machine with evenly dispersed hot air includes a cocoon drying room 3, a feeding belt 1, a receiving box 12 and several conveyor belts 15, and the conveyor belts 15 are located in the cocoon drying room 3. Inside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com