Rotary screen dryer

A dryer and rotary screen technology, applied in the direction of dryers, drying, progressive dryers, etc., can solve the problem of unstable product quality, different hot air penetration capabilities, and different drying degrees at the left and right ends of the fabric and in the middle Uniformity and other issues to achieve the effect of ensuring stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

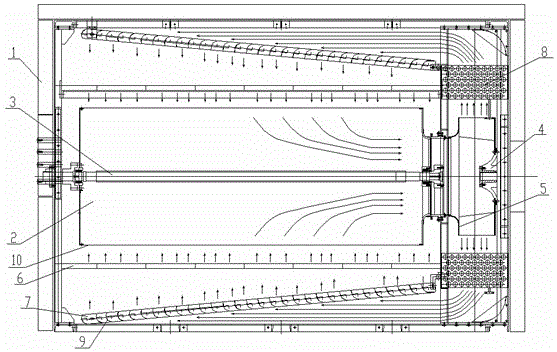

[0011] A rotary screen dryer, comprising a frame 1 and a rotary screen 2, the rotary screen 2 is installed in the frame 1 through a rotating shaft 3, the right end of the rotary screen 2 is provided with a suction fan 4 installed on the frame 1, and the rotary screen 2 is mounted on the frame 1. The right end of the net 2 is provided with an opening and an air guide pipe 5 is installed, and the air guide pipe 5 is provided with upper and lower air vents, and the upper and lower ends of the circular net 2 are provided with an air uniform plate 6, and the air uniform plate 6 is provided with some ventilation holes, so that the wind can be evenly distributed. A deflector 7 is arranged between the upper and lower ends of the plate 6 and the frame 1, and a radiator 8 is arranged at the upper and lower vents of the air guide pipe 5; become smaller, the deflector 7 is provided with several guide plates 9, the distance between the guide plates 9 gradually decreases from right to left, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com