Filtration irrigation device

A technology of infiltration irrigation and porous filter membrane, applied in the direction of spraying device, spraying device, watering device, etc., can solve the problems of block cleaning, fast speed, fast impurity speed, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

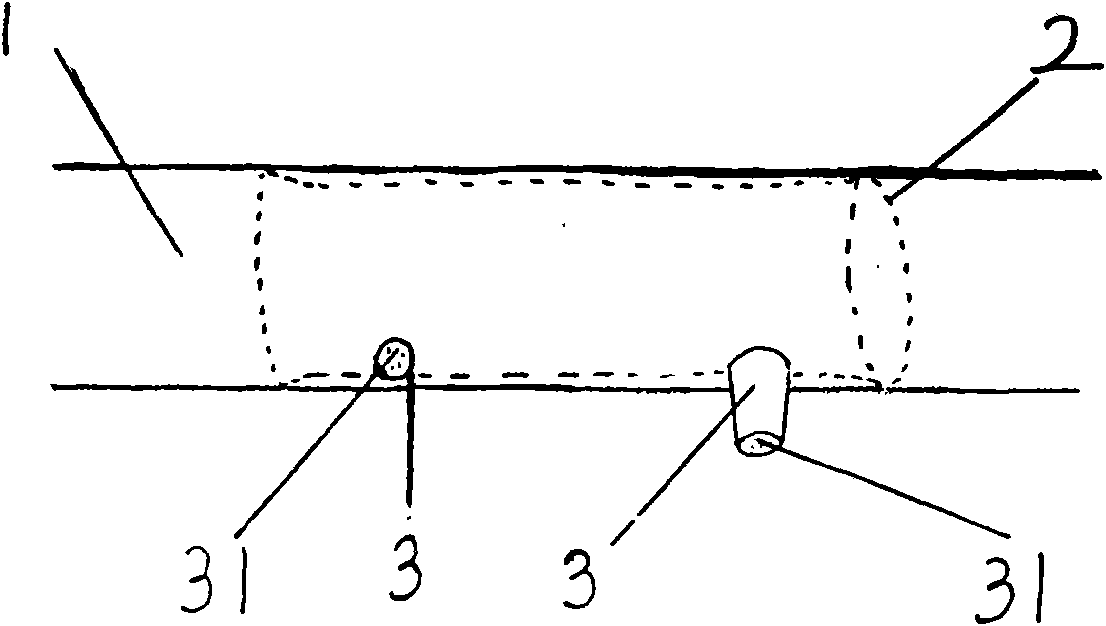

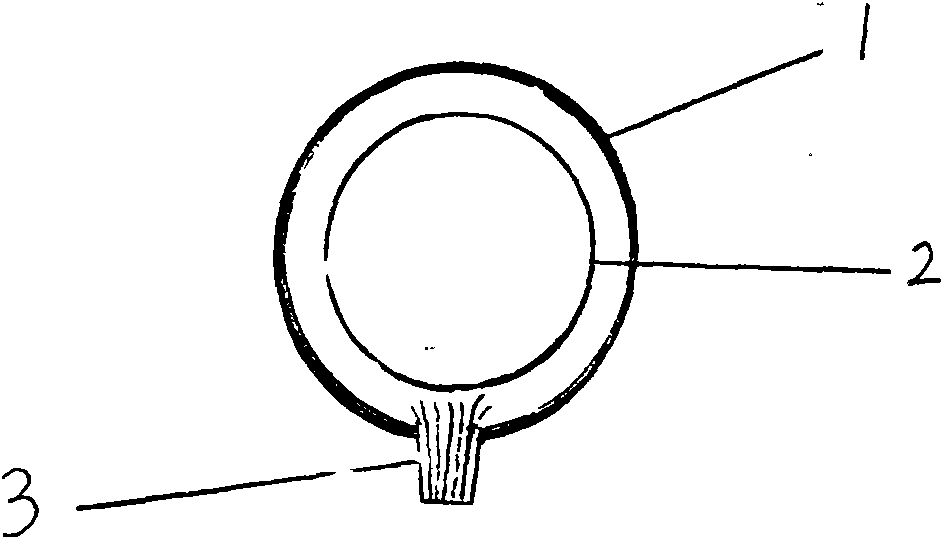

[0017] Such as figure 1 , figure 2 Shown, a kind of permeation irrigation device comprises tubular shell 1 and the porous filter membrane 2 that covers on the inner wall of tubular shell 1, the limited flow hole 31 in the restrictor 3 on the tubular shell 1 communicates with the inside and outside of tubular shell 1, porous filter The edge part of the membrane 2 is tightly sealed with the inner wall of the tubular shell without water leakage, and the water can only flow out of the percolation irrigation device after passing through the porous filter membrane 2 and the restrictor hole 31 in the restrictor 3, and become irrigation water. The restrictor 3 consists of one or several restrictor holes. The flow restrictor 3 can be directly opened on the pipe wall within the coverage of the porous filter membrane, or the flow restrictor can be extended to the outside of the infiltration irrigation device by extending the flow restrictor. Multiple flow restrictors can distribute ir...

Embodiment 2

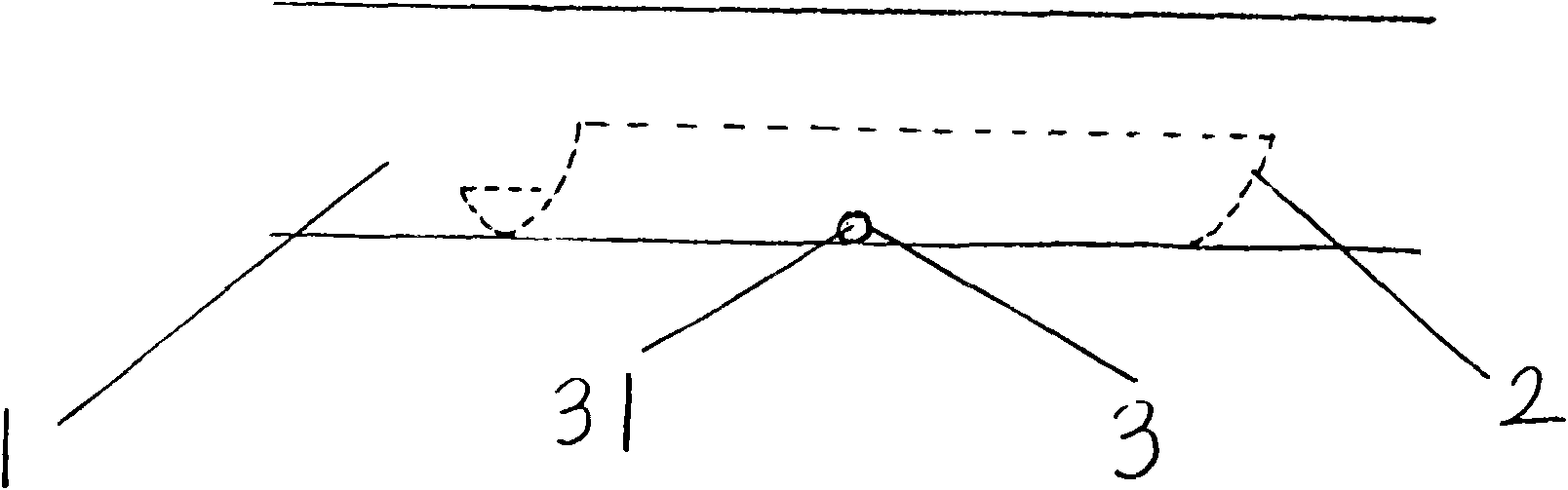

[0019] as figure 1 The change, image 3 , Figure 4 The porous filter membrane of the medium infiltration irrigation device only covers a small part of the infiltration irrigation device. The porous filter membrane 2 has a pore size of less than 10 microns, and its peripheral edge is closely connected with the inner wall of the tubular shell. Only when the flow-limiting hole 31 in the device 3 flows out can it become irrigation water, and the water flow in the tubular shell plays the role of cleaning up impurities when flowing through the surface of the porous filter membrane. The pore diameter of the flow restrictor is larger than that of the porous filter membrane, and its water seepage capacity is smaller than that of the porous filter membrane.

Embodiment 3

[0021] as image 3 further changes in Figure 5 The porous filter membrane 2 of the middle infiltration irrigation device is placed in the protruding external shell 12 on the tubular shell 1 , and the water outlet end of the external shell 12 is connected with the flow restrictor 3 . The external casing 12 communicates with the tubular casing 1, and part of the water in the tubular casing 1 enters the external casing 12, passes through the porous filter membrane 2, then enters the restrictor hole 31 in the restrictor 3, and then flows out to become irrigation water. The water flow in the tubular housing 1 has a cleaning effect on the impurities on the porous filter membrane 2 doing Brownian motion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com