Giant magnetostrictive hydraulic pump and working method thereof

A giant magnetostrictive pump and giant magnetostrictive technology, applied in the field of hydraulic control, can solve the problems of large fluid resistance, large flow resistance of passive valve plate, non-adjustable bias magnetic field, etc., and achieve stable working performance and wide adjustment range , the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

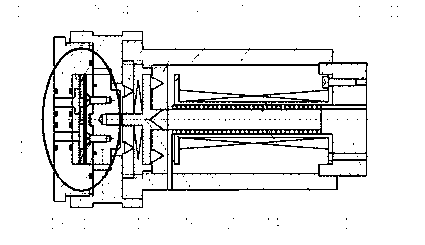

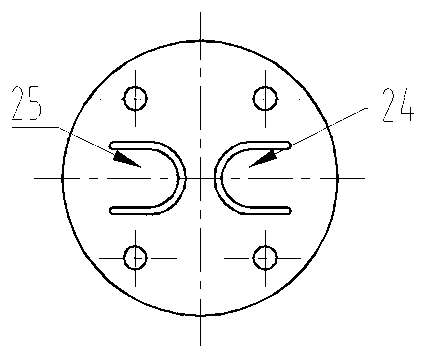

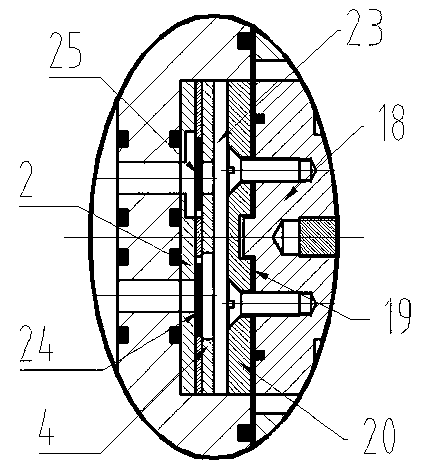

[0034] like figure 1 , as shown in 2 and 3, a new type of giant magnetostrictive pump includes a giant magnetostrictive electric-machine converter and a hydraulic pump head, which is characterized in that:

[0035] The above-mentioned giant magnetostrictive electro-mechanical converter includes an outer cover 8, an end cover 5 installed on the left end of the outer cover, a base 12 installed on the right end of the outer cover, an output rod 15 installed in the left end cover, and is installed on the left side and in the outer cover. The magnetic block 6 at the right end of the output rod, the coil bobbin 7 installed at the right end of the outer cover and fixed to the base, and the magnetic field generation (drive and bias) unit 10 is installed on the coil bobbin.

[0036] It also includes a giant magnetostrictive rod 9 installed in the coil frame and a cooling pipe 13 tightly wound on the giant magnetostrictive rod. One side of the block 6 is the magnetic output end, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com