Metal switch zipper and its manufacturing process

A manufacturing process and metal technology, applied in the field of metal switch zipper and its manufacturing process, can solve the problems of weak wire installation, poor circuit stability and high production cost, and achieve the advantages of reducing occupied space, long service life and simplifying production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

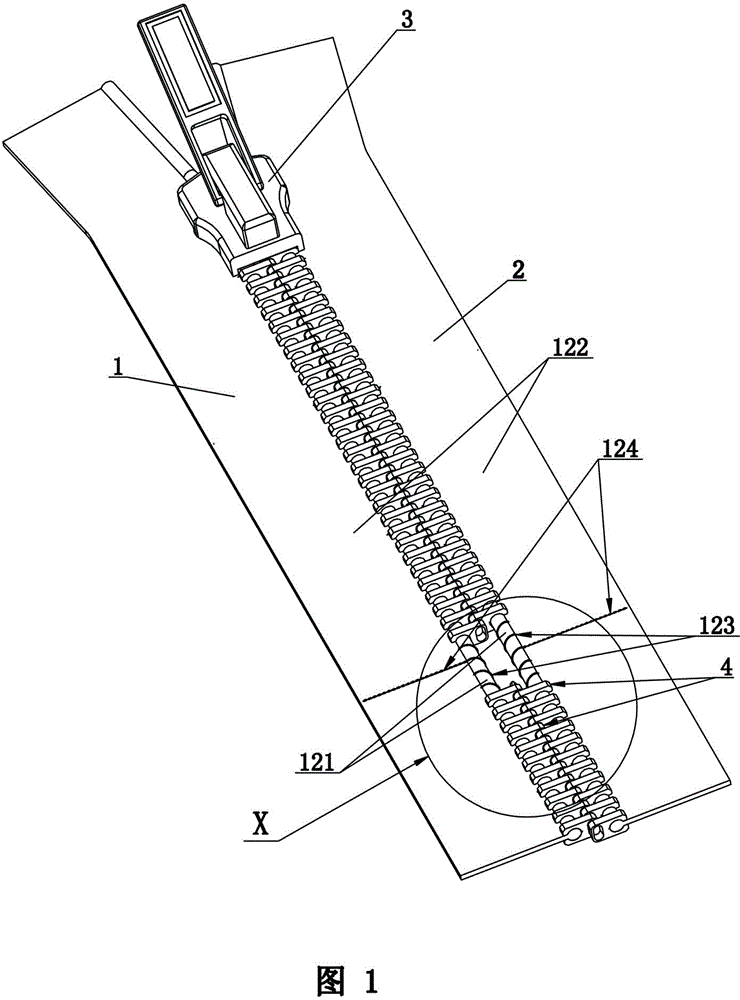

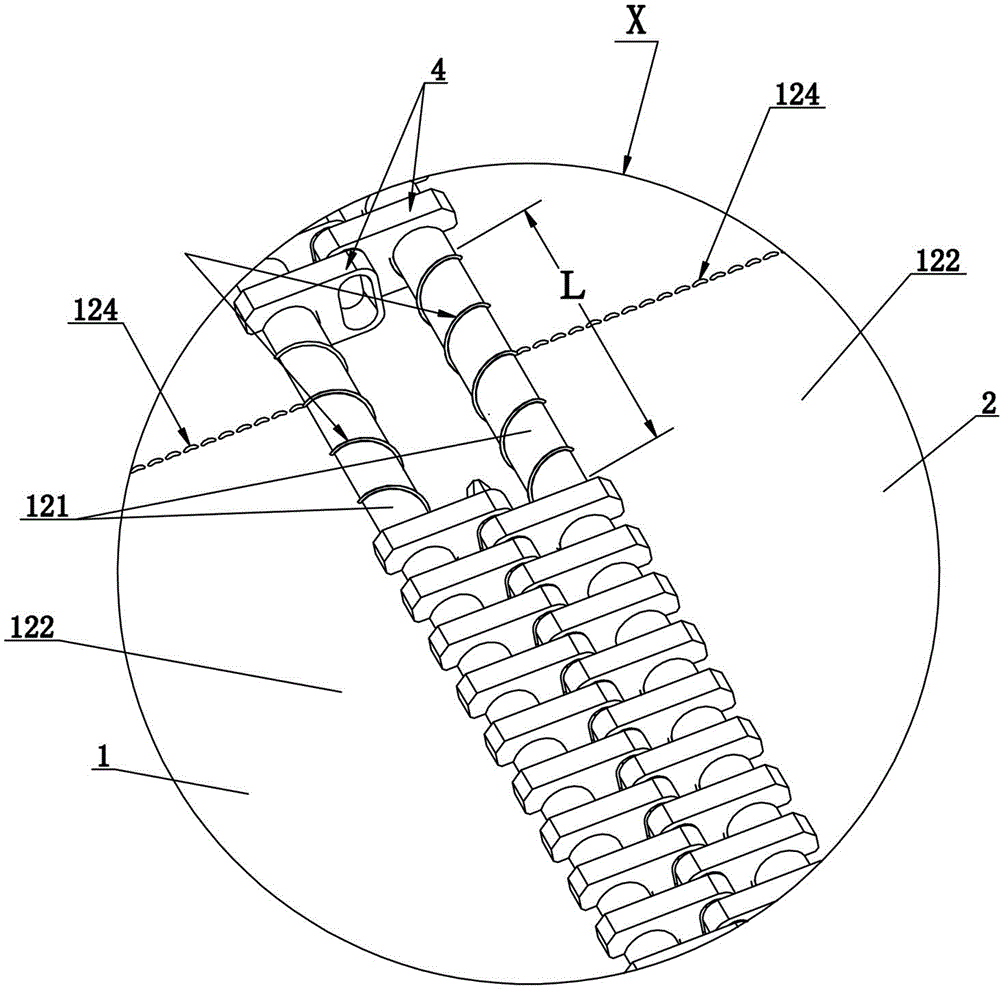

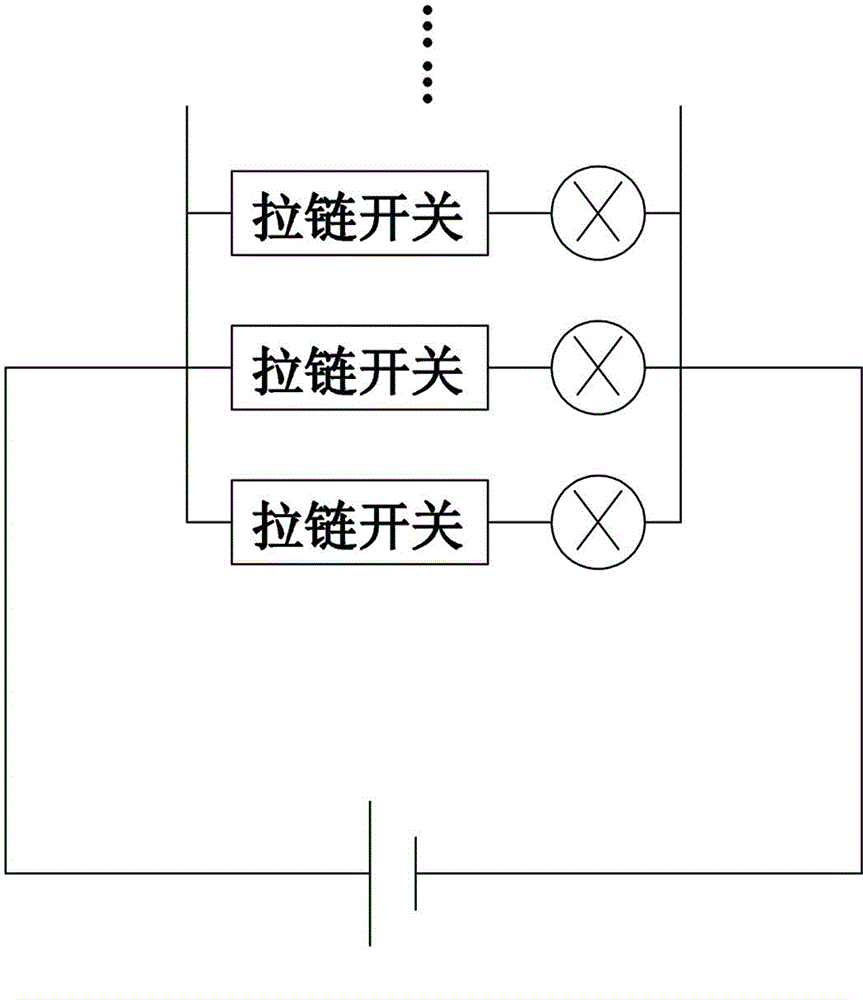

[0025] refer to figure 1 , figure 2 , metal switch zipper, including left cloth belt 1, right cloth belt 2 and slider 3, left cloth belt 1, right cloth belt 2 all comprise cloth reinforcement 121 and cloth surface 122 integrally connected, the thickness of this cloth reinforcement 121 is greater than this cloth According to the thickness of the surface 122, metal chain elements 4 are respectively assembled on the cloth bars 121 of the left cloth tape 1 and the right cloth tape 2. There is a first conductive wire 123, which is arranged to extend along the length direction of the fabric tendon 121. In the winding state, the length L of the first conductive wire 123 along the axial direction (such as figure 2 (shown by the mark L in the middle) is not less than 1 cm; the above-mentioned metal chain element 4 is set on the cloth bar 121 so as to clamp the first wire 123; the above-mentioned cloth surface 122 of the left cloth tape 1 and the right cloth tape 2 The second conduc...

Embodiment approach 2

[0033] refer to Figure 4 , the only difference from Embodiment 1 is that the numbers of the first wires 123 and the second wires 124 provided on the left cloth tape 1 and the right cloth tape 2 are different. The left cloth tape 1 and the right cloth tape 2 of this embodiment Five above-mentioned first wires 123 are respectively provided, and five of the first wires 123 are respectively equipped with one above-mentioned second wire 124; certainly, the configuration quantity of the first wire 123 and the second wire 124 can also be adjusted according to actual needs. set up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com