An online optical detector

An optical detector and light source technology, applied in the field of optical detection, can solve the problems of inability to detect two surfaces of a PCB board at the same time, affecting the accuracy of picture information, insufficient light intensity of the light source, etc., to achieve compact structure, improve heat dissipation efficiency, and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

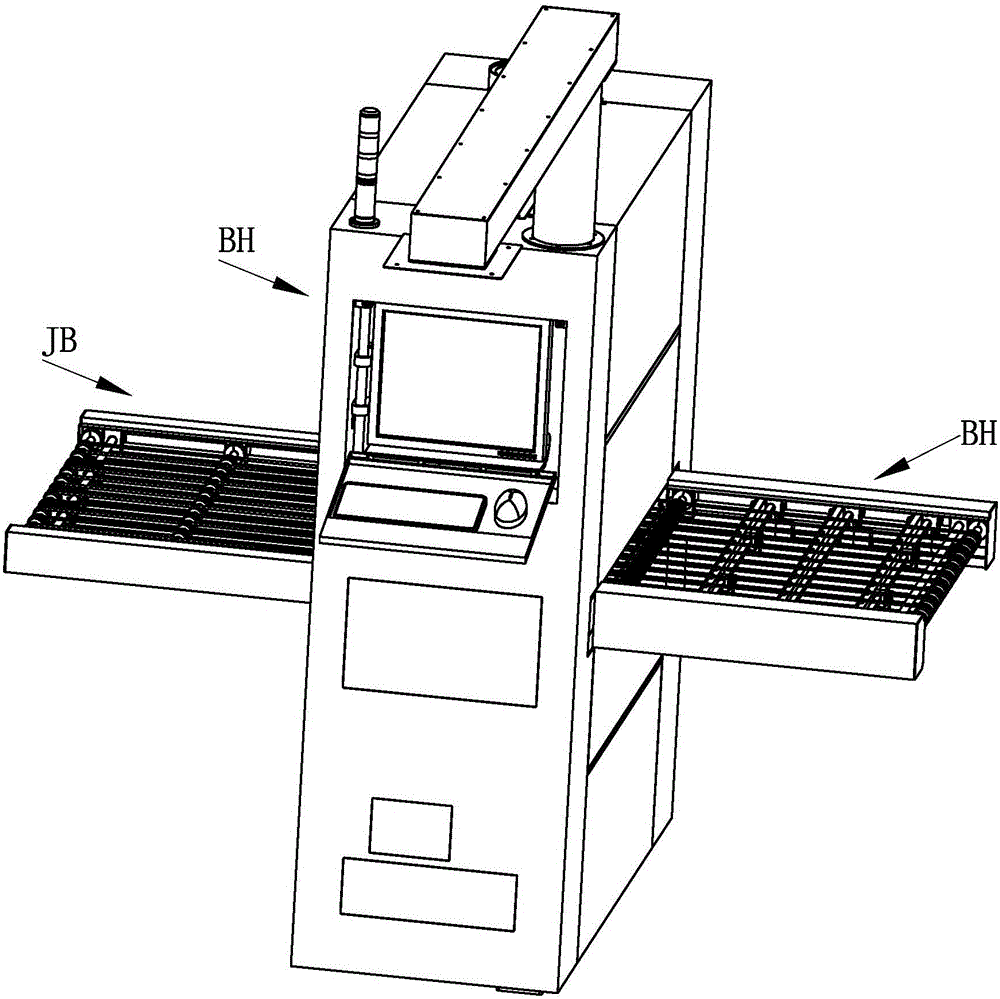

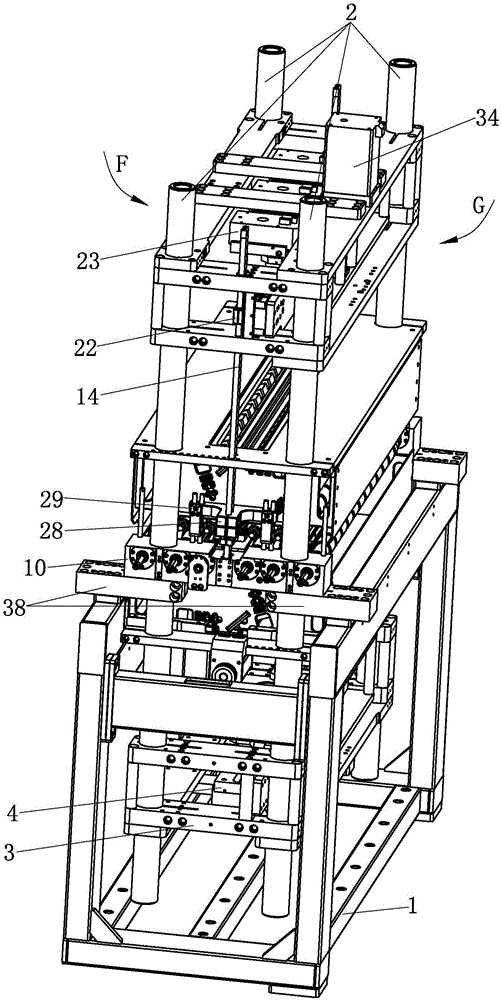

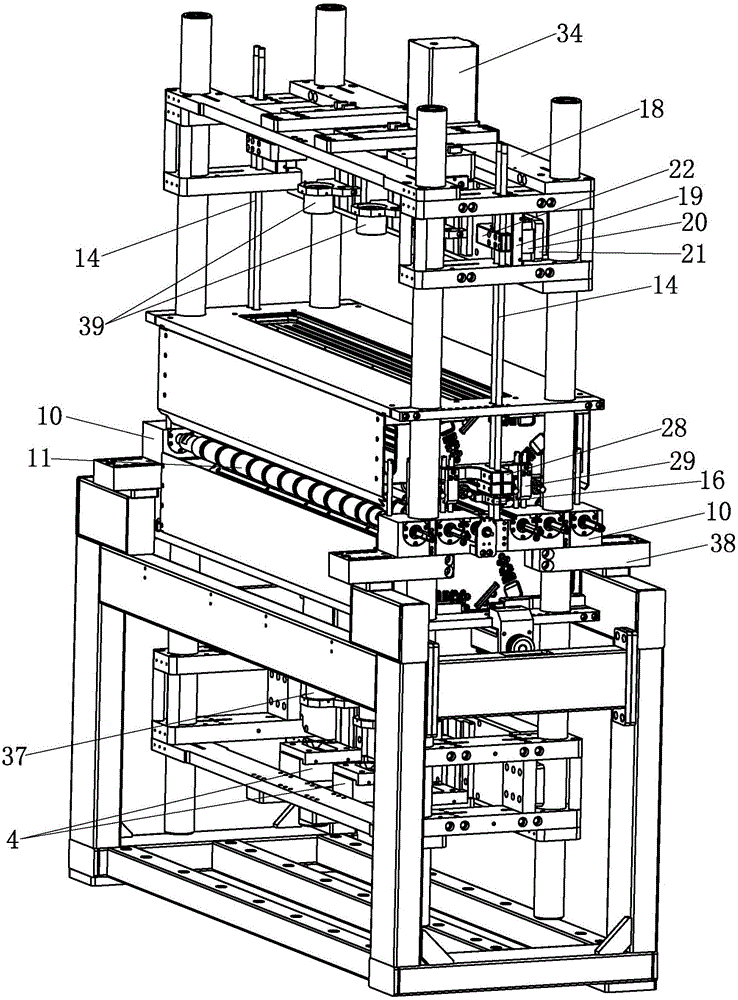

[0046] Such as Figures 1 to 12 As shown, an online optical detector is a complex system. In order to achieve the purpose of protection, it is equipped with a protective cover BH, and at the same time it is equipped with a board-in device JB and a board-out device CB. These two devices It is located on both sides of the protective cover BH, and the function of the board feeding device JB is to facilitate the input of the PCB board to be tested, and the board feeding device JB has a positioning function, so as to locate the PCB board passing through it, so that the PCB board and the protection board The camera inside the housing BH is centered so that the camera can subsequently collect image information of the two surfaces of the PCB board. The function of the board output device CB is to facilitate the smooth output of the detected PCB board, and the board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com