Novel flavor compound and preparation method, application and composition thereof

A technology of compounds and compositions, applied in the field of new fragrance compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

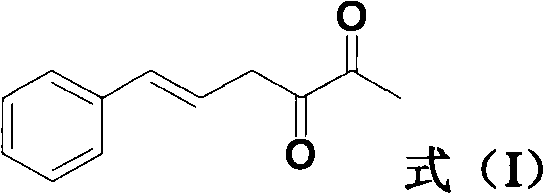

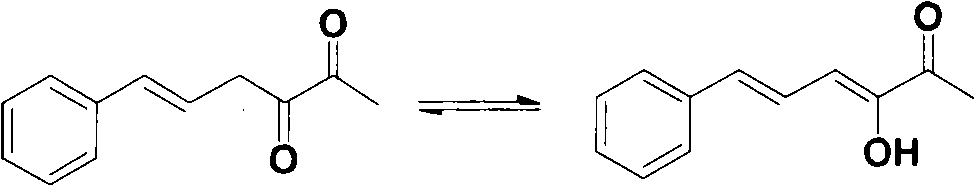

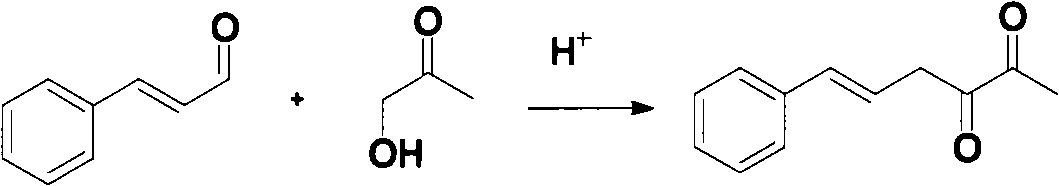

[0024] Example 1: Synthesis of 3-hydroxy-6-phenyl-3,5-hexadien-2-one

[0025] Mix 100g of cinnamaldehyde and 286g of hydroxyacetone at room temperature to obtain a mixture of cinnamaldehyde and hydroxyacetone; add 63g of 15% hydrochloric acid into the reaction flask, raise the temperature to 50°C, and then add the above cinnamon dropwise under stirring at a constant rate within 2h A mixture of aldehyde and hydroxyacetone, keep it for 2 hours after dripping;

[0026] Then, 110 g of water was added to the reaction solution, the temperature was raised to 82° C. and the reaction was continued for 2 h; after the reaction, the product was filtered while hot and recrystallized with ethyl acetate to obtain 39.4 g of white crystals. After testing, its melting point is 127.8-128.1°C; the yield is 27.7%.

[0027] 1 H NMR(CDCl 3 , 400MHz): d 2.45 (s, 3H), 6.39 (d, J = 11.2 Hz, 1H), 6.84 (d, J = 12 Hz, 1H), 6.86 (s, 1H), 7.28-7.34 (m, 2H) , 7.35-7.39 (m, 1H), 7.52-7.54 (m, 2H) ppm;

[0028] 13 C...

Embodiment 2

[0030] Example 2: Olfactory evaluation of pure 3-hydroxy-6-phenyl-3,5-hexadien-2-one

[0031] The olfactory evaluation of pure 3-hydroxy-6-phenyl-3,5-hexadien-2-one was completed by an evaluation team composed of several professionals. The compound has a pure and herb-like aroma, with tobacco and bean aromas aroma.

Embodiment 3

[0032] Example 3: The olfactory evaluation of 3-hydroxy-6-phenyl-3,5-hexadien-2-one in the composition

[0033] Component

(%weight ratio)

(%weight ratio)

(%weight ratio)

5%

2%

2.5%

[0034] Squalane

50%

40%

60%

Glyceryl triisocaprylate

20%

25%

20%

20%

23%

17.5%

3-hydroxy-6-phenyl-3,5-

Hexadiene-2-one

5%

10%

0%

Total

100%

100%

100%

[0035] Squalane, glyceryl triisocaprylate and hydroxyethyl cellulose can all be purchased directly from the market.

[0036] Test group 1 and 2 had a light herb-like aroma with tobacco and bean aroma, while test group 3 had no such aroma. In addition, the evaluation team conducted T test on the composition of test group 1, test group 2 and test group 3 in an open environment. 0h , T 72 , T 288h The olfactory evaluation results show that the intensity of the fragrance will decrease with time, but the natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com