Magnetic nanoparticles and preparation method thereof

A magnetic nanoparticle and nanoparticle technology, applied in the chemical field, can solve the problems of magnetic materials to be studied, and achieve the effects of superior chemical and thermal stability, fast speed, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] According to the method of the embodiment of the present invention, the carboxyl-functionalized ferric iron tetroxide is used as the magnetic core, 1,3,5-tris(4-aminophenyl)benzene and 1,3,5-triformylphloroglucinol To synthesize magnetic nanoparticles for functional monomers, the preparation process is as follows:

[0075] (a) In a 50mL two-necked round-bottomed flask, 50mg of carboxy-functionalized ferric oxide and 80mg of 1,3,5-tris(4-aminophenyl)benzene were added to 11mL of tetrahydrofuran, and Sonicate for 20min.

[0076] (b) With the product of step (a), the mixture was mechanically stirred at 65°C for 30 minutes, so that part of 1,3,5-tris(4-aminophenyl)benzene was first anchored to the carboxyl-functionalized tetroxide through hydrogen bonds. The tri-iron surface forms a bridge effect to obtain covalent organic framework nanomaterials.

[0077] (c) Disperse 60 mg of 1,3,5-triformylphloroglucinol evenly in 4 mL of tetrahydrofuran, and add it and 200 μL of aceti...

Embodiment 2

[0079] The magnetic nanoparticles (Fe) that this embodiment obtains to embodiment 1 3 o 4 @TAPB-Tp) conducted detailed characterization experiments to demonstrate the successful preparation and excellent physicochemical properties of magnetic nanoparticles. details as follows:

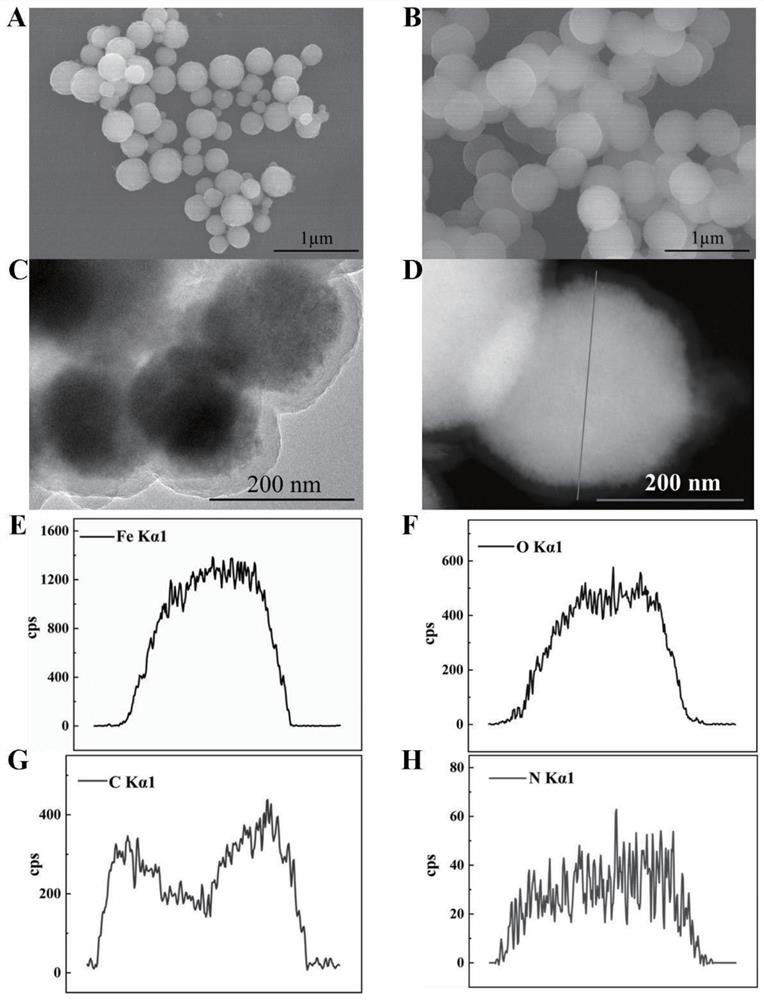

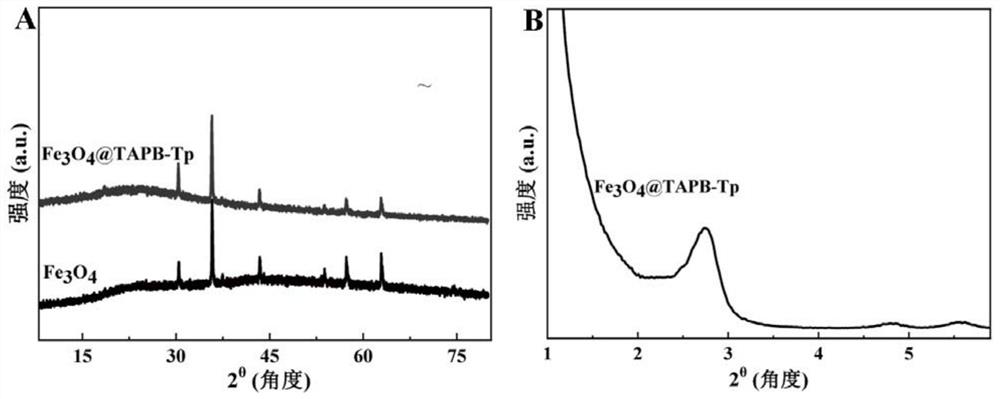

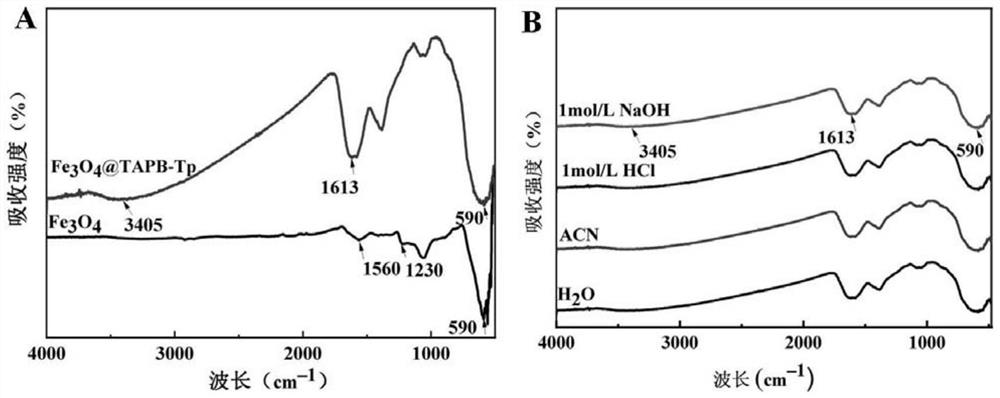

[0080] 1. Carboxyl-functionalized ferric oxide (Fe 3 o 4 ) and magnetic nanoparticles (Fe3 o 4 @TAPB-Tp) for scanning electron microscopy, transmission electron microscopy, and energy dispersive spectroscopy. The result is as figure 1 As shown, from Fe 3 o 4 ( figure 1 A) and Fe 3 o 4 @TAPB-Tp( figure 1 B) The SEM image shows that the prepared Fe 3 o 4 and Fe 3 o 4 @TAPB-Tp has regular spherical morphology and good dispersion. compared to Fe 3 o 4 , Fe 3 o 4 The surface morphology of @TAPB-Tp changed significantly, indicating that the covalent organic framework shell was successfully encapsulated in Fe 3 o 4 surface. Fe 3 o 4 The TEM image of @TAPB-Tp further proves that the co...

Embodiment 3

[0089] In this embodiment, the magnetic nanoparticles (Fe 3 o 4 @TAPB-Tp) studied its feasibility for the adsorption of five zearalenone mycotoxins (ZEAs) in complex samples as follows:

[0090] Fe was studied by adsorption static adsorption and dynamic adsorption experiments 3 o 4 Adsorption performance of @TAPB-Tp on five ZEAs. In short, prepare 2mL standard solutions of each target substance with a concentration of 2mg / L, 5mg / L, 10mg / L, 20mg / L, 30mg / L, 40mg / L, and 50mg / L, and add 1.0mg of Fe 3 o 4 @TAPB-Tp oscillating adsorption for 120min and configuration 2mL concentration is 0.005mg / L, 0.05mg / L, 0.1mg / L, 0.25mg / L, 0.5mg / L, 1mg / L, 1.25mg / L, 1.5mg / L , 2mg / L standard solution of each target substance, respectively add 0.50mg of Fe 3 o 4 @TAPB-Tp was shaken and adsorbed for 120min. Calculate Fe by the following formula (1) 3 o 4 Maximum adsorption capacity of @TAPB-Tp for five ZEAs.

[0091]

[0092] Among them, Q is the maximum adsorption capacity, C 0 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com