Carbon-coated manganous-manganic oxide composite material and preparation method and application thereof

A manganese tetroxide composite material and a technology of manganese tetroxide, which are applied in the field of materials, can solve the problems of difficulty in maintaining the chemical state of manganese oxides, low reusability and the like, and achieve good reusability, good use value and application prospects. , the effect of efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

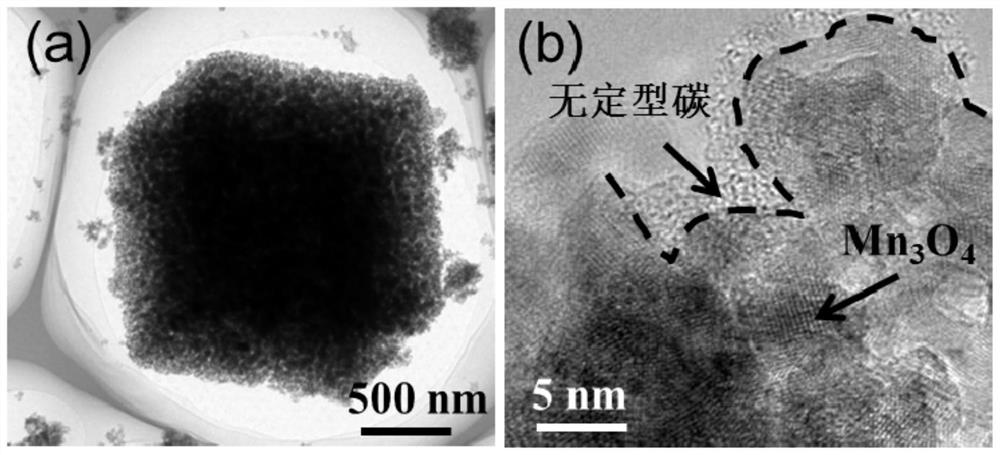

[0039]A carbon package is wrapped in tetra-manganese composites, with tetrasian mono-manganese as the core, wrapped in a non-formal carbon layer in the surface of the tetrashydoxide.

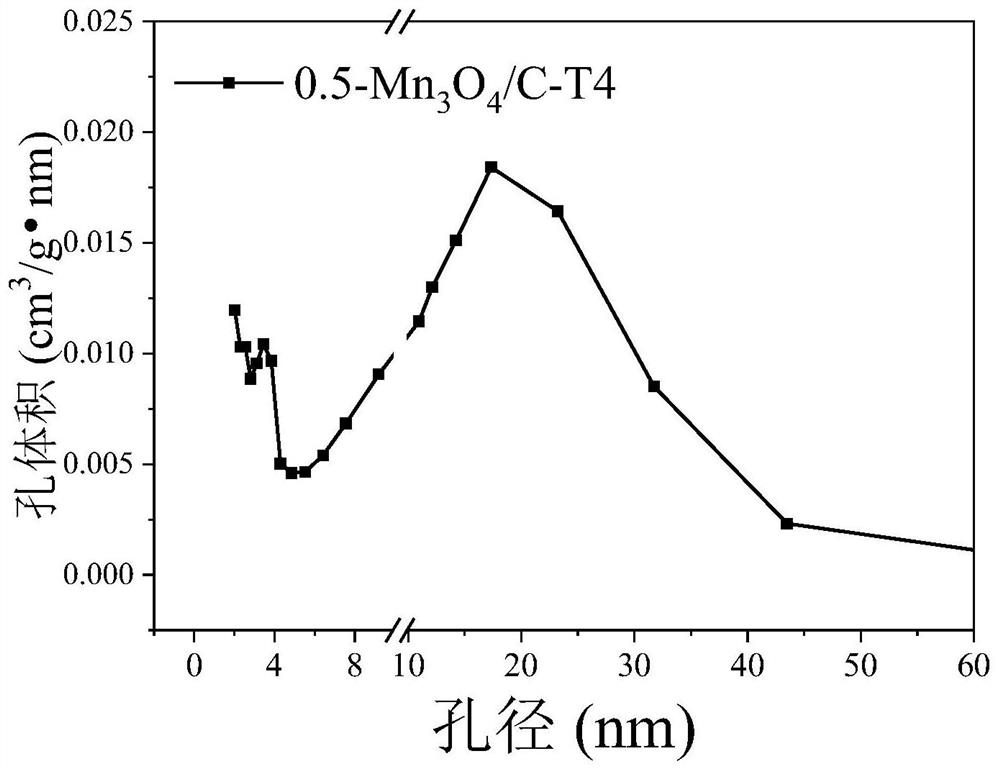

[0040]In the present embodiment, the carbon dioxide composite material has a graded aperture structure, and the aperture distribution is mainly in the range of 2 nm to 5 nm and 10 nm to 30 nm.

[0041]In the present embodiment, the ferrous dioxide composite material wrapped in the carbon is a nano-cube, a side length of 500 nm to 800 nm.

[0042]In this embodiment, the inner casing is a nanocougroup composed of nano-tetranedoxide particles; the thickness of the amorphous carbon layer is 2 nm to 4 nm.

[0043]A method of preparing a quadroformous mono-manganese composite material wrapped in the above-described example in the present embodiment, with glucose and potassium permanganate as a raw material, two-step synthesis of high temperature calcination after the first hydrothermal synthesis, including the followin...

Embodiment 2

[0047]A method of preparing a carbon wrapped tetrasoxide complex material, which is substantially identical to Example 1, and the difference is only: in Example 2, potassium permanganate (KMNO)4The concentration of 35 mm, that is, the molar ratio of glucose with potassium permanganate is 1: 1.

[0048]The aperture distribution in the carbon dioxide composite material obtained in Example 2 was mainly concentrated in a range of 2 nm to 5 nm and 8 nm to 25 nm, named 1-Mn.3O4 / C-T4.

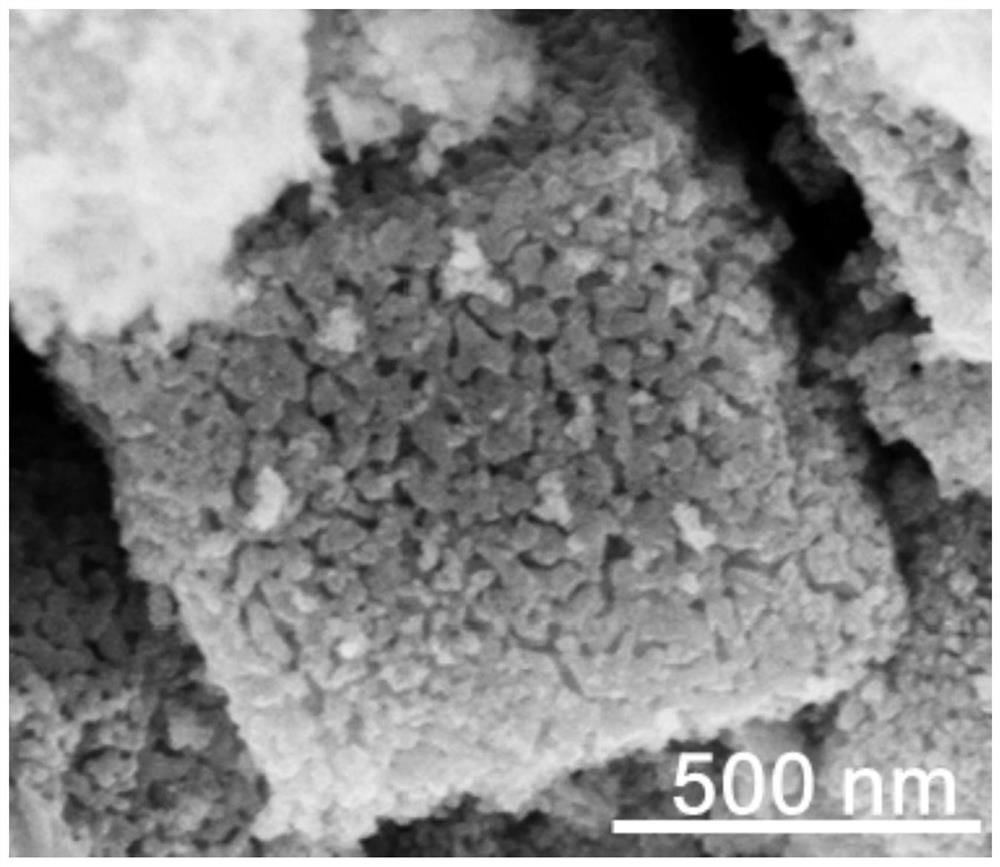

[0049]The tetrarolate compound (0.5-Mn) wrapped in the carbon encapsulated in this Example 1 (0.5-Mn3O4 / C-T4) Perform a scanning electron microscope (SEM) imaging observation,figure 1 Indicated. byfigure 1 It can be seen that carbon-wrapped tetramented mono-manganese composites (0.5-Mn3O4 / C-t4) Exhibit the nano-cube structure of a rule, a side length of 500 nm to 800 nm, and is assembled from many small particles (tetraned and trifanganganese particles), and the surface has a significant gully aperture structu...

Embodiment 3

[0054]A preparation method of carbon-coated trimanganese tetroxide composite material is basically the same as that of Example 1, except that: in Example 3, the calcination temperature is 800°C.

[0055]The pore size distribution of the carbon-coated trimanganese tetroxide composite material prepared in Example 3 is mainly concentrated in the range of 2nm to 5nm, named 0.5-Mn3O4 / C-T8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com