Temporary overhead device and method for high-speed railway ballastless track lines suitable for high-speed traffic

A ballastless track and high-speed rail technology, applied to roads, tracks, ballast layers, etc., can solve problems affecting line operation efficiency, poor integrity of overhead lines, and cumbersome construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

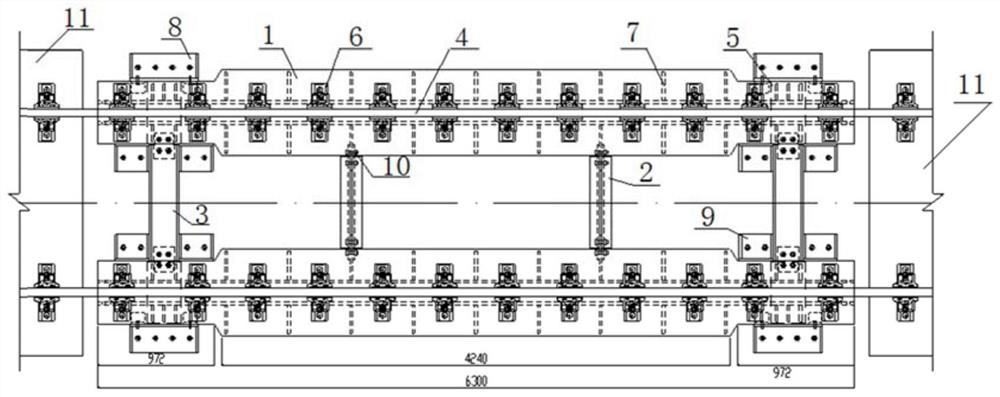

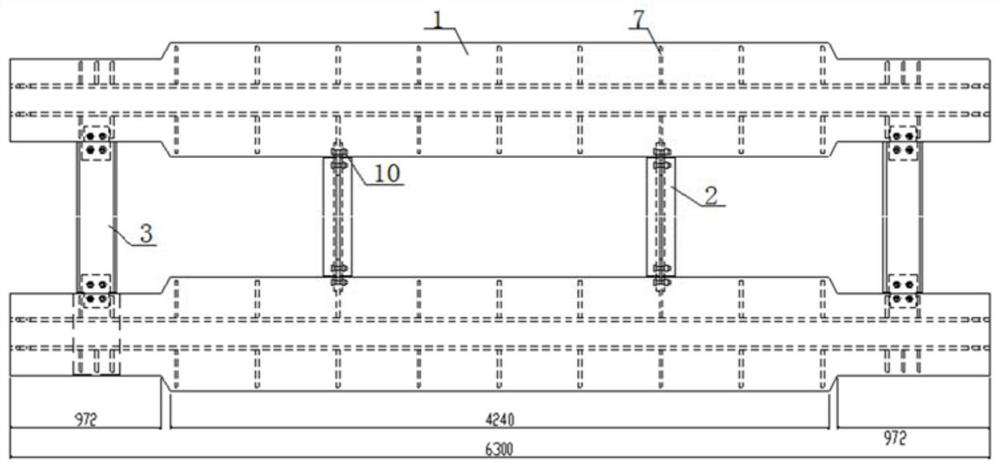

[0071] A temporary overhead device for high-speed rail ballastless track lines suitable for high-speed traffic. When the high-speed rail ballastless track is damaged within a track slab, such figure 1 As shown, it includes a steel backing beam 12, a support 5, a limiting device and a fastener 6. Wherein, in the present embodiment, the total length of the steel pad beam is about 6300mm, and the span is about 5200mm. A steel pad beam with one hole can just replace a Type II track slab. Horizontal and longitudinal centerlines coincide. The steel pad beam 12 is composed of two longitudinal beams 1, two intermediate beams 2 and two end beams 3 between the two longitudinal beams 1, and the two longitudinal beams 1 are respectively located directly below the two steel rails 4 , which mainly plays the role of supporting the line rail; the end beam 3 and the middle beam 2 are arranged perpendicular to the longitudinal beam 1 respectively. The top of the longitudinal beam 1 is provide...

Embodiment 2

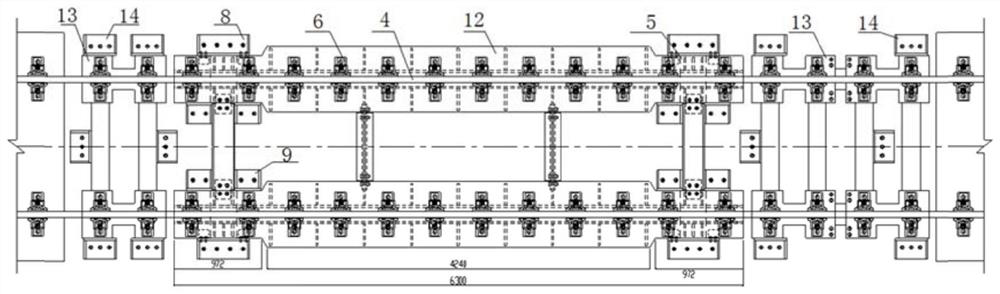

[0078] When the high-speed rail ballastless track line is damaged in the range where the two track slabs 11 are connected, the two track slabs 11 will be removed at the same time, and the steel pad beam 12 will be erected above the diseased area. A transition section support 13 of corresponding length is set between the end and the normal track plate 11, such as figure 2 shown. There is still a gap between the transition section support 13 and the steel backing beam.

[0079] The structure of the steel pad beam in this embodiment is consistent with that of the steel pad beam in Embodiment 1.

[0080] The transition section support 13 includes steel members A15 , concrete sleepers 17 and fasteners 6 . Both ends of the concrete sleeper 17 are respectively fixed with steel members A15 by bolts, and the steel members A15 include a top plate, two vertical webs and two vertical connecting plates located below the top plate, such as Figure 7a~7c It is a structural schematic diag...

Embodiment 3

[0085] When a disease occurs within only one track slab in the high-speed rail ballastless track line, it only needs to remove the track slab, and the temporary line can be erected by using four parts: steel backing beam, support, limit device and fastener. The method of erecting temporary lines with this overhead device is as follows:

[0086] 1) Use a rail cutting machine to cut the rail above the diseased track slab, and the breakpoints at both ends of the rail extend 3 to 5m from the end of the track slab longitudinally along the track, and temporarily remove the rail;

[0087] 2) Cut open the wide and narrow joints at both ends of the track slab, release the prestress of the track slab, and remove the track slab with jacks, spreaders and lifting equipment;

[0088] 3) Use a chisel tool to chisel off the mortar bonding layer on the supporting layer to ensure that the exposed supporting layer surface is flat, and then clean the supporting layer surface. On the cleaned suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com