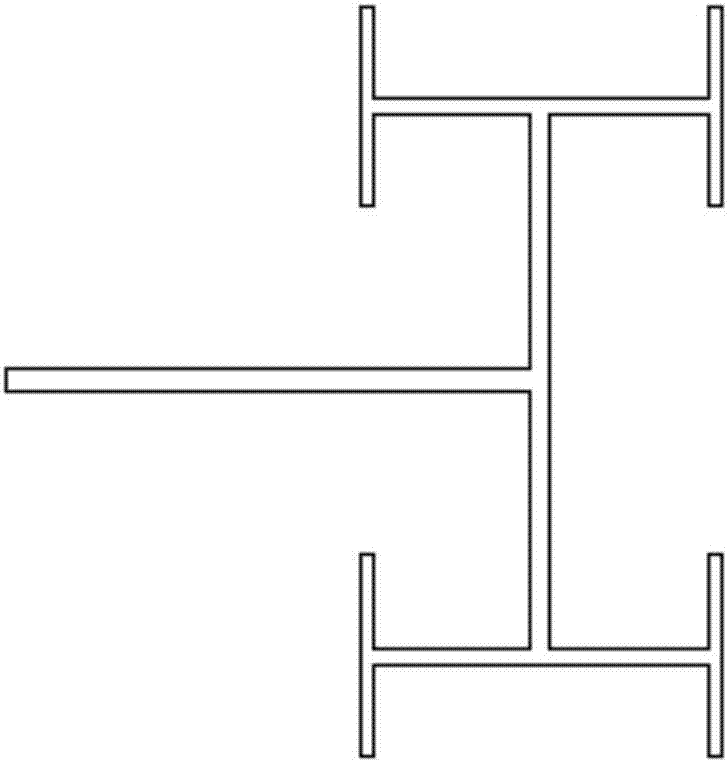

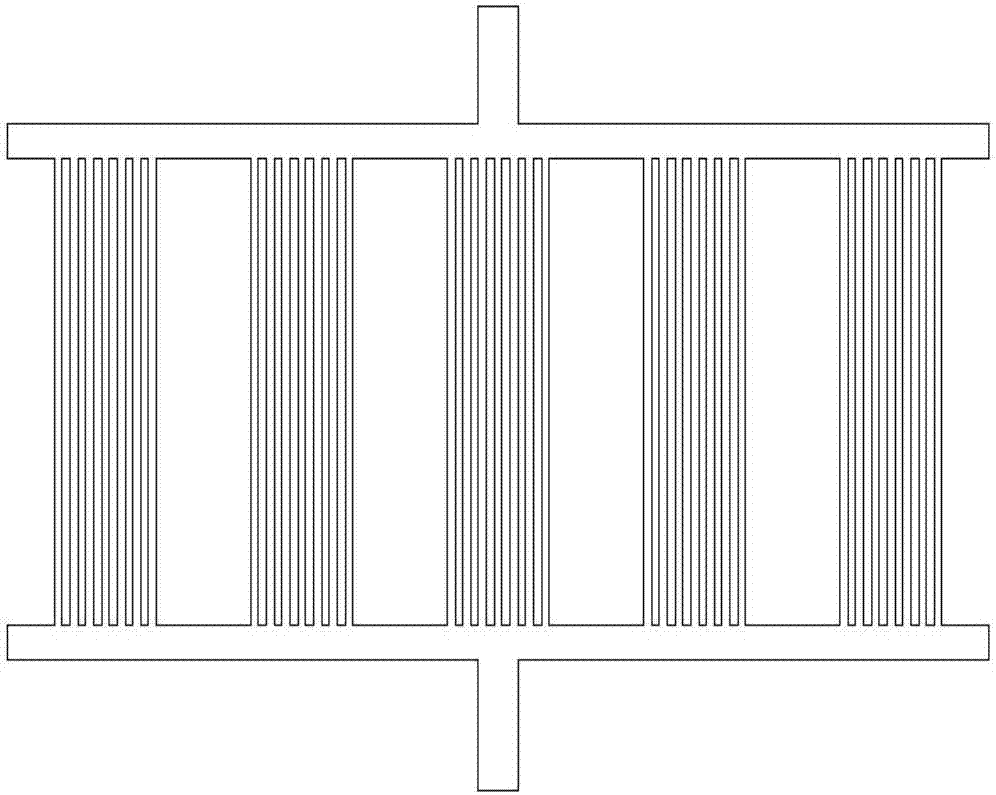

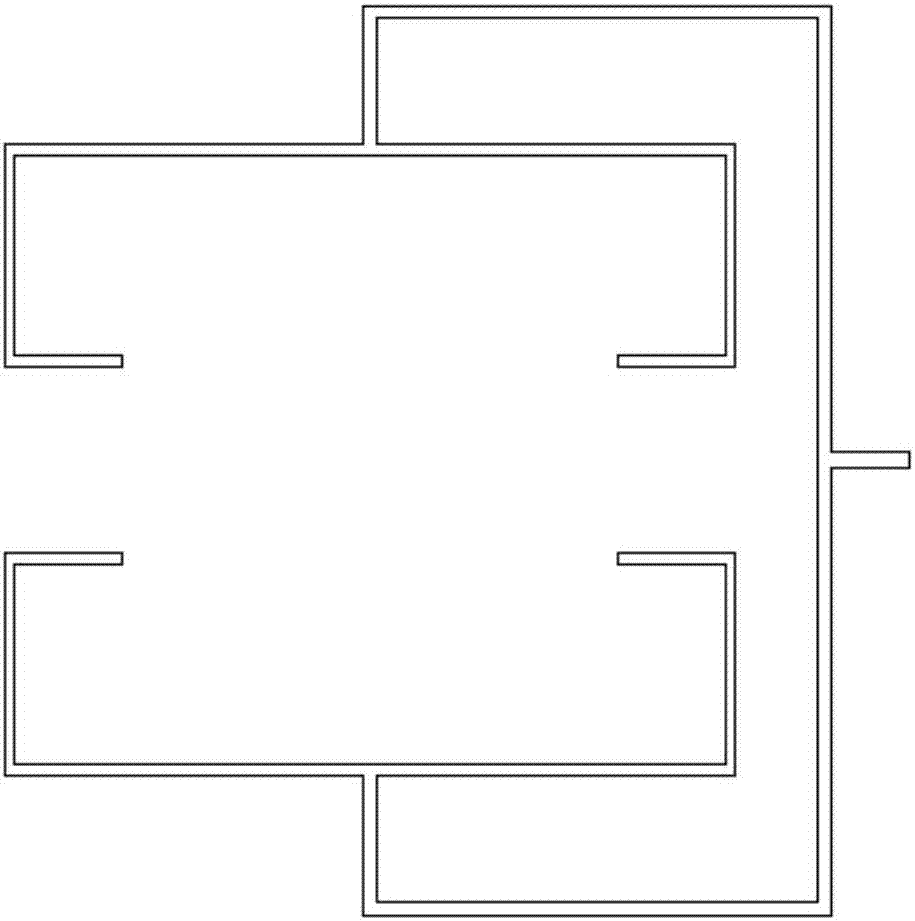

Micro-channel cold plate structure

A microchannel and cold plate technology, applied in the direction of deicing/drying devices, etc., can solve the problems such as the need to improve the heat dissipation capacity of the microchannel cold plate, the single topology structure of the microchannel cold plate, and the poor temperature consistency, and achieve the uniformity of channel distribution. Good, easy to process, good temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0043] In order to verify the superior performance of the microchannel cold plate structure provided by the present invention in terms of heat dissipation, the traditional rectangular flat microchannel cold plate structure and the common tree-shaped microchannel cold plate structure (two-layer structure) are used as references, and three kinds of microchannel cold plate structures are used. The channel cold plate structure is compared and analyzed by thermal simulation.

[0044] According to the principle of equal parameters, the following settings are specially made: the cold plate material and size are the same; the channel size is the same, and the cross section is rectangular; the substrate thickness is the same; the fluid working medium is the same; the heat load is the same; the flow channel coverage area is basically the same.

[0045] Based on this, the detailed thermal simulation calculation model parameters and boundary condition parameters are set as follows:

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com