Adaptive filling expansion scree tube and expanding method thereof

A self-adaptive, screen technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of limited activity, expansion interruption, high cost, etc., to achieve simple mechanical devices, reduce wear speed, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

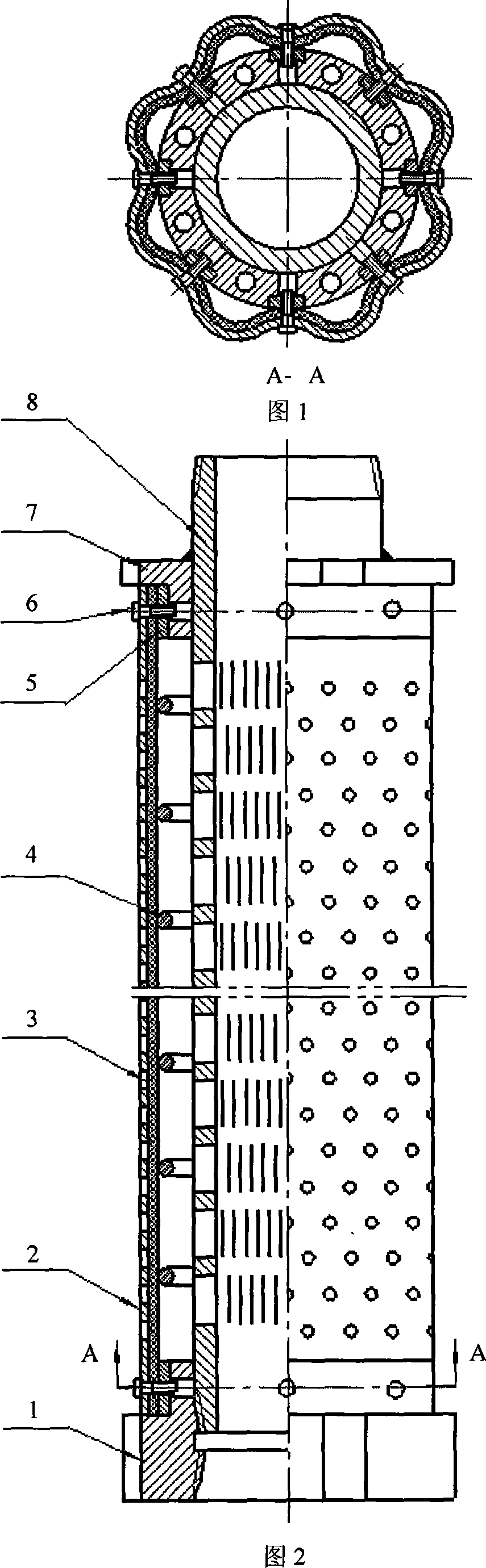

[0013] See Figure 1. The self-adaptive filling expansion screen of the present invention adopts a plurality of expansion screws and expansion blocks evenly distributed on the circumference to fix the radially expandable composite filter element and the radially expandable cover on the special filling collar. There is also a filling hole in the axial direction of the hoop to provide a passage for filling liquid.

[0014] See Figure 2. The self-adaptive filling expansion screen of the present invention mainly consists of eight parts. 1 is a special filling collar, which is mainly used for the connection between adaptive filling expansion screens, providing filling channels, supporting expansion blocks, etc.; 2 is a radially expandable cover, which is a radial corrugated tubular structure, with There are radial through-holes or radial through-slits, which mainly expand freely during expansion, basically without plastic deformation, and are mainly used to protect radially expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com