Hollow stabilizer, and steel pipe for hollow stabilizers and method for production thereof

A manufacturing method and technology for stabilizer bars, which are applied in the directions of manufacturing tools, transportation and packaging, furnace types, etc., can solve problems such as fatigue failure of hollow stabilizer bars, and achieve the effects of excellent fatigue durability and delayed failure characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0083] (Manufacturing Example 1 of Stabilizer Bar) Cold Forming

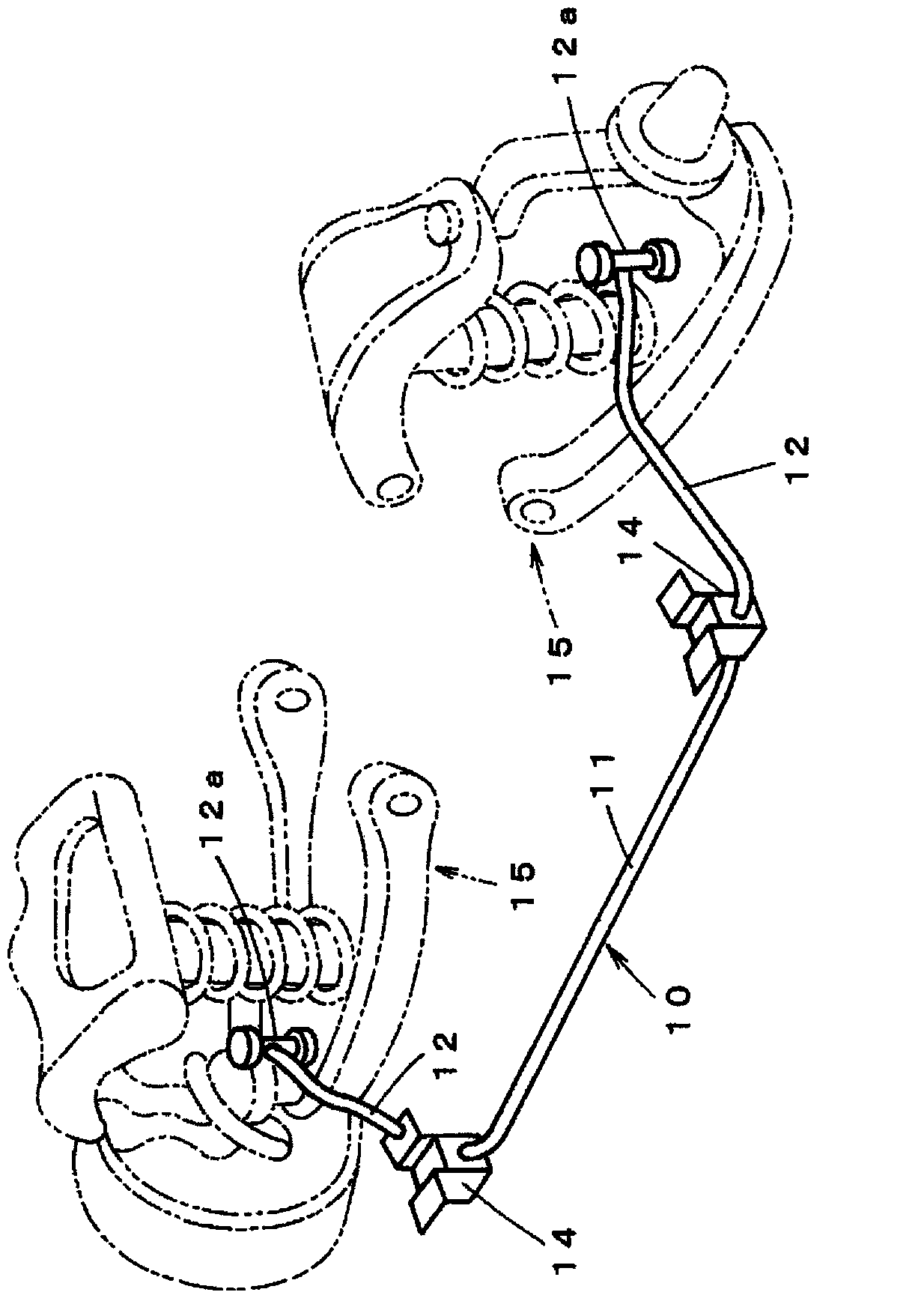

[0084] Next, use Figure 8 , Manufacturing Example 1 of the stabilizer bar will be described. Bending and forming steel pipes (electrically welded pipes, seamless pipes, heat reducing pipes, or their drawn pipes) cut to a specified length into figure 2 The desired shape shown (process: bending forming), using furnace heating or electric heating or high-frequency heating device, heated to the austenite temperature range (process: heating), quenching in water (or other quenching medium) ( Process: Quenching). Further, the thermally deformed stabilizer bar is corrected to the desired shape of the stabilizer bar (process: shape correction), and tempered (process: tempering), only the outer surface of the tempered pipe, or the outer surface and Both inner surfaces are shot blasted (process: shot blasting), and painted with a desired paint (process: painting). However, if restraint quenching is performed, shape c...

manufacture example 2

[0085] (Manufacturing Example 2 of Stabilizer Bar) Thermoforming

[0086] Next, use Figure 9 , Manufacturing Example 2 of the stabilizer bar will be described. Heating steel pipes (electrically welded pipes, seamless pipes, heat reducing pipes, or their drawn pipes) cut to a predetermined length by furnace heating, electric heating, or high-frequency heating equipment to the austenite temperature range (process: heating) , bent into figure 2 The desired shape shown (process: bending forming) is quenched in water (or other quenching medium) (process: quenching). Further, the thermally deformed stabilizer bar is corrected to the desired shape of the stabilizer bar (process: shape correction), and tempered (process: tempering), only the outer surface of the tempered pipe, or the outer surface and Both inner surfaces are shot blasted (process: shot blasting), and painted with a desired paint (process: painting). However, if restraint quenching is performed, shape correction ...

Embodiment 1

[0089] The present invention will be described more specifically below by way of examples.

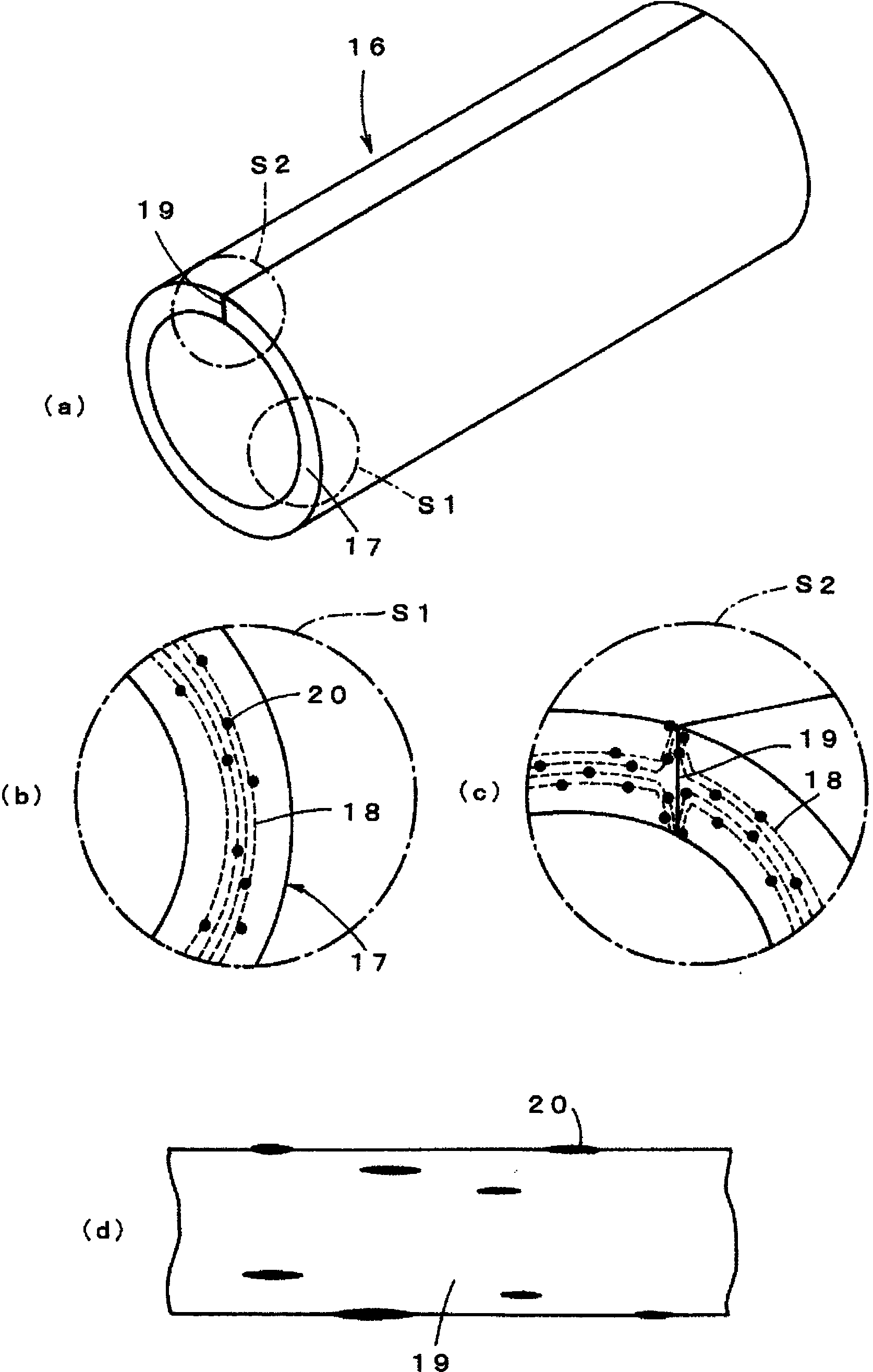

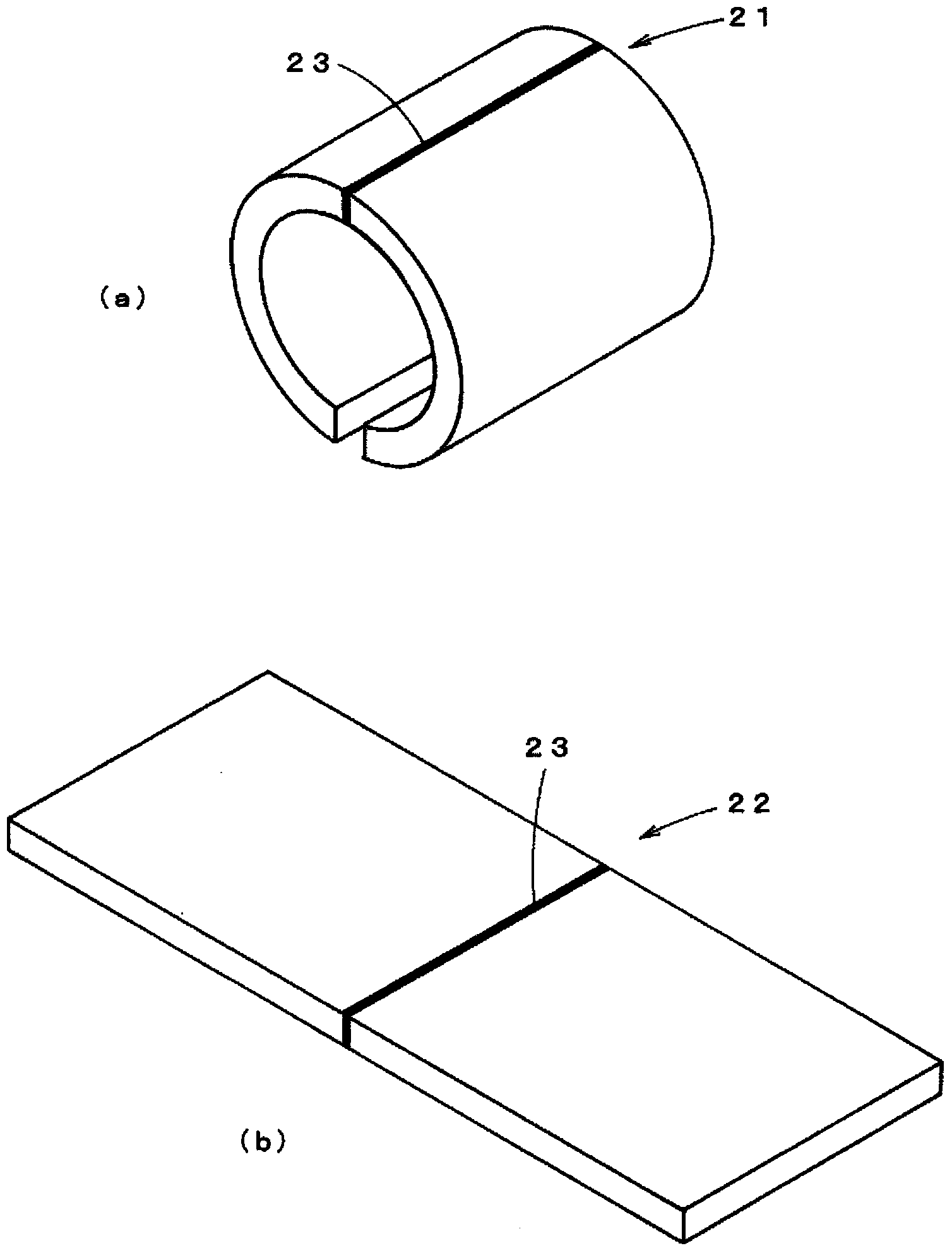

[0090]Each steel type having the composition shown in Table 1 was smelted and cast to form a slab, and the obtained slab was heated to 1200° C., hot-rolled at a hot finishing temperature of 890° C. and a coiling temperature of 630° C. to produce A steel plate with a thickness of 5mm is formed. These steel sheets were cut into predetermined widths, roll-formed into tubes, and then welded by high-frequency electric welding to manufacture electric-welded steel pipes with an outer diameter of 90 mm. Furthermore, the obtained electric-welded steel pipe was heated to 980°C by high-frequency induction heating, and reduced-rolled to produce a steel pipe with an outer diameter of 30 mm and a wall thickness of 4.5 mm (t / D: 0.15) or a steel pipe with an outer diameter of 30 mm. 22mm, 4.5mm thick (t / D: 0.20) steel pipe (steel pipe for hollow stabilizer bars). Immediately after reducing rolling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com