Pitch-varying two-sided internal and external composite-meshing silent chain transmission system

A technology of transmission system and variable pitch, which is applied in the direction of transmission chain, transmission device, chain ring, etc., can solve the problems of affecting engine performance, poor motion accuracy, poor fatigue durability, etc., and achieve the reduction of polygon effect and shock and vibration, chain Effect of reducing polygonal effect and improving fatigue durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

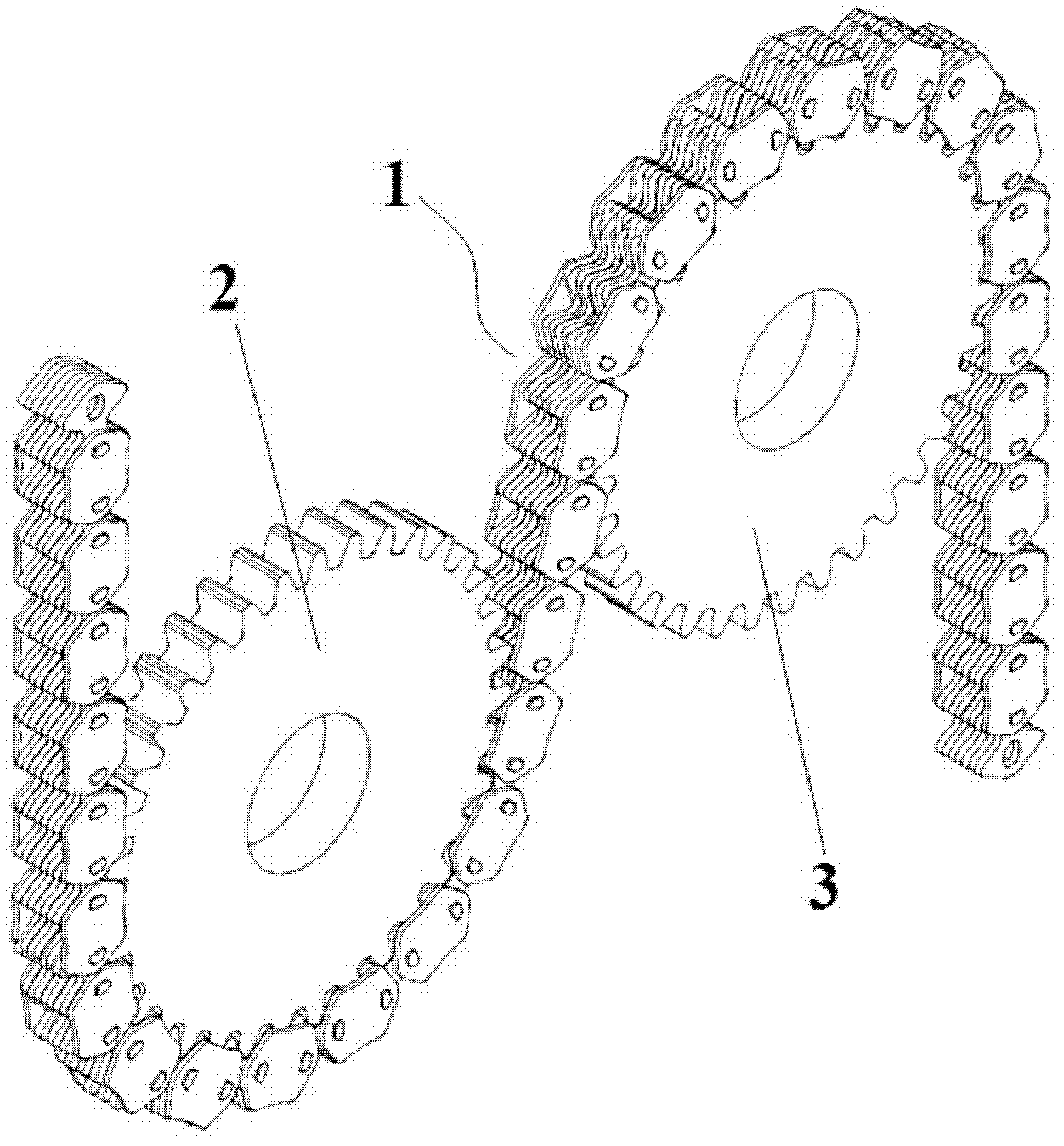

[0026] figure 1 It is an assembly drawing of the present invention, and it can be seen from the figure that a variable-pitch double-sided internal and external compound meshing toothed chain transmission system of the present invention is mainly composed of a chain 1, a sprocket A2 and a sprocket B3. One side of the chain 1 is engaged with the sprocket A2 for transmission, and the other side of the chain 1 is engaged with the sprocket B3 for transmission, so as to realize the transmission of force and torque.

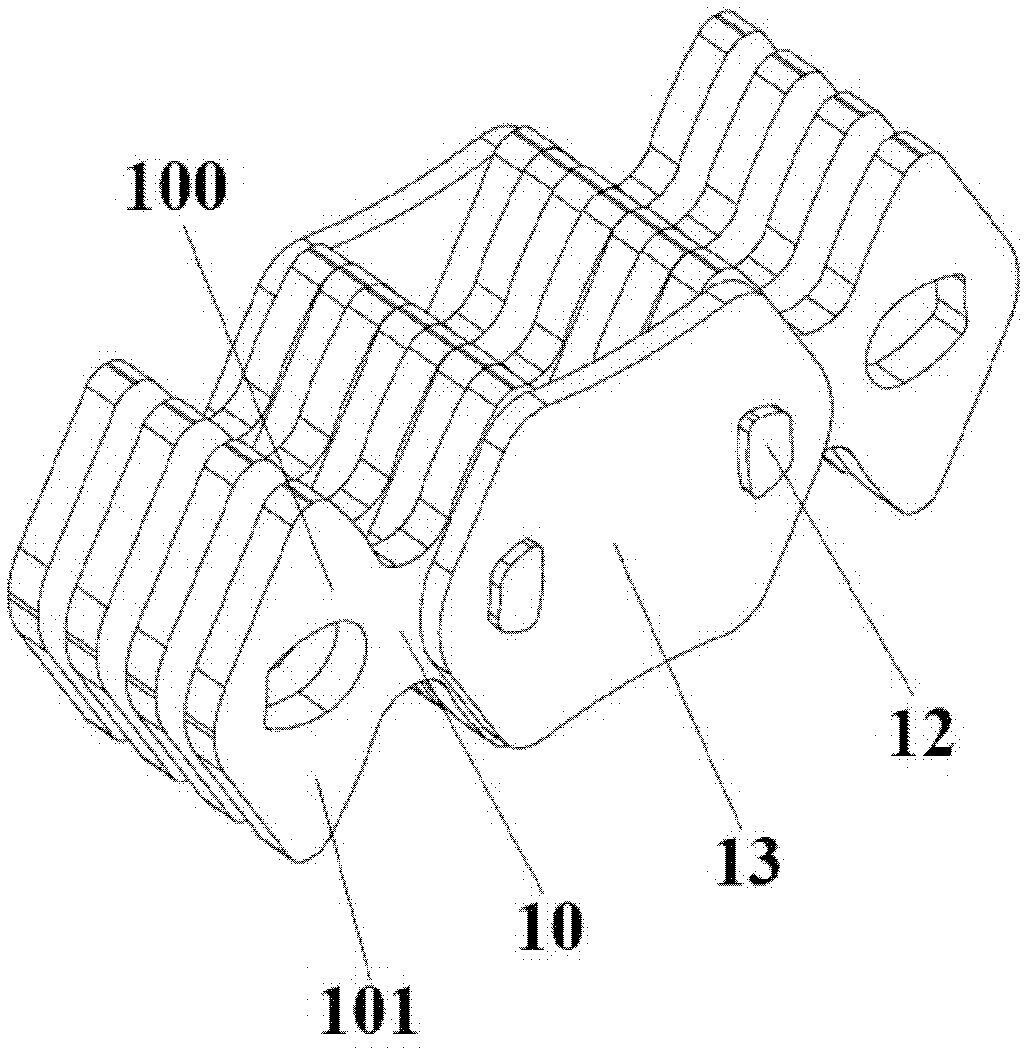

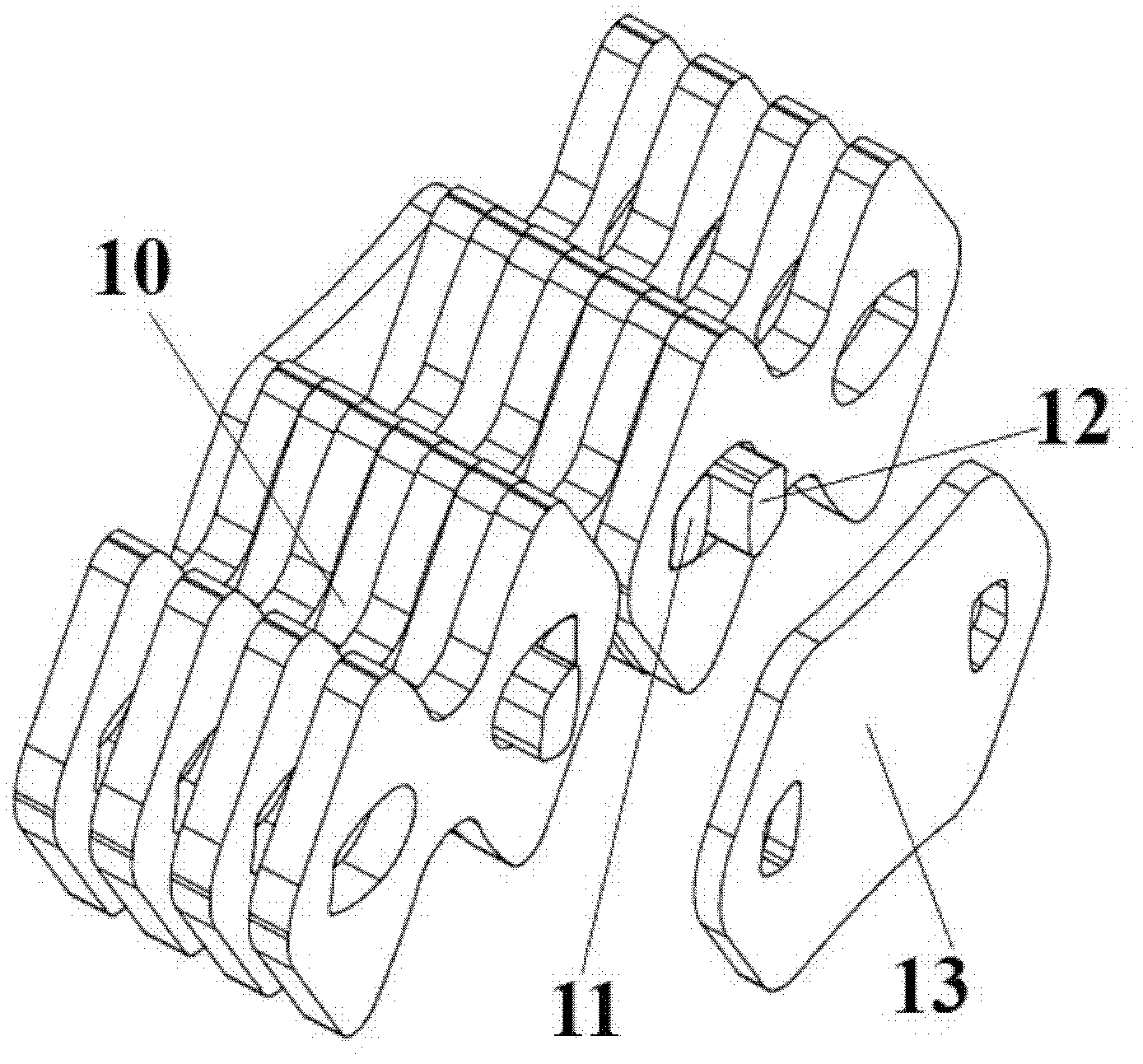

[0027] figure 2 yes and image 3 It is an assembly drawing of the chain in the present invention, and it can be seen that the chain 1 is composed of multiple groups of working chain plates 10 , short rolling pins 11 , long rolling pins 12 and guide pieces 13 . Wherein, the short rolling pins 11 and the long rolling pins 12 pass through the chain plate holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com