crawler walking mechanism

A traveling mechanism, tracked technology, used in tracked vehicles, motor vehicles, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

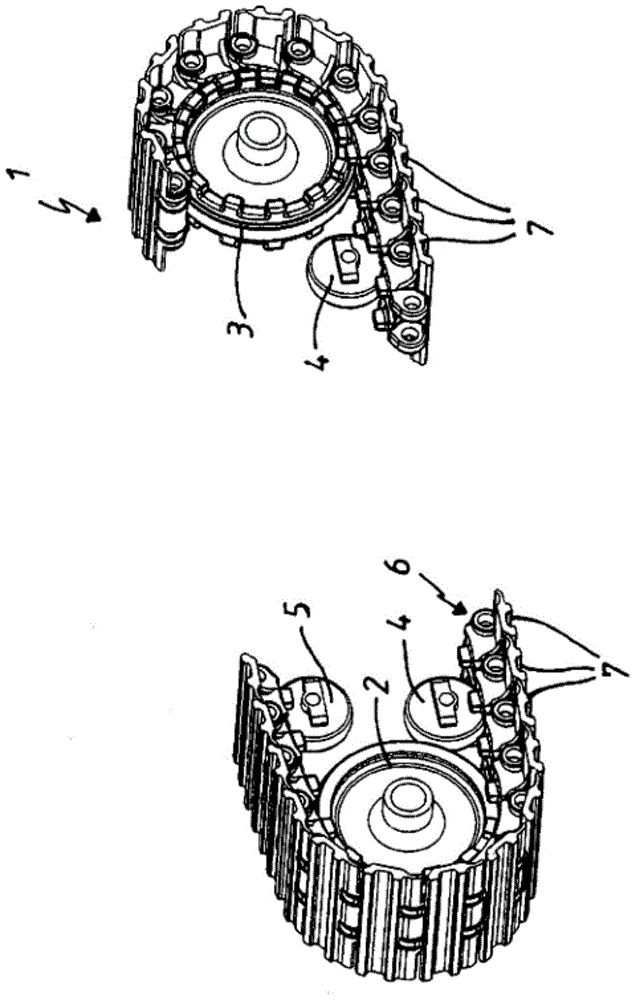

[0032] figure 1 A schematic diagram of the tracked undercarriage 1 according to the invention is shown in a perspective view. The following components can be seen: guide pulley 2 , drive pulley 3 , track pulley 4 , idler pulley 5 and endless chain 6 formed by a plurality of track shoes 7 articulated and interconnected.

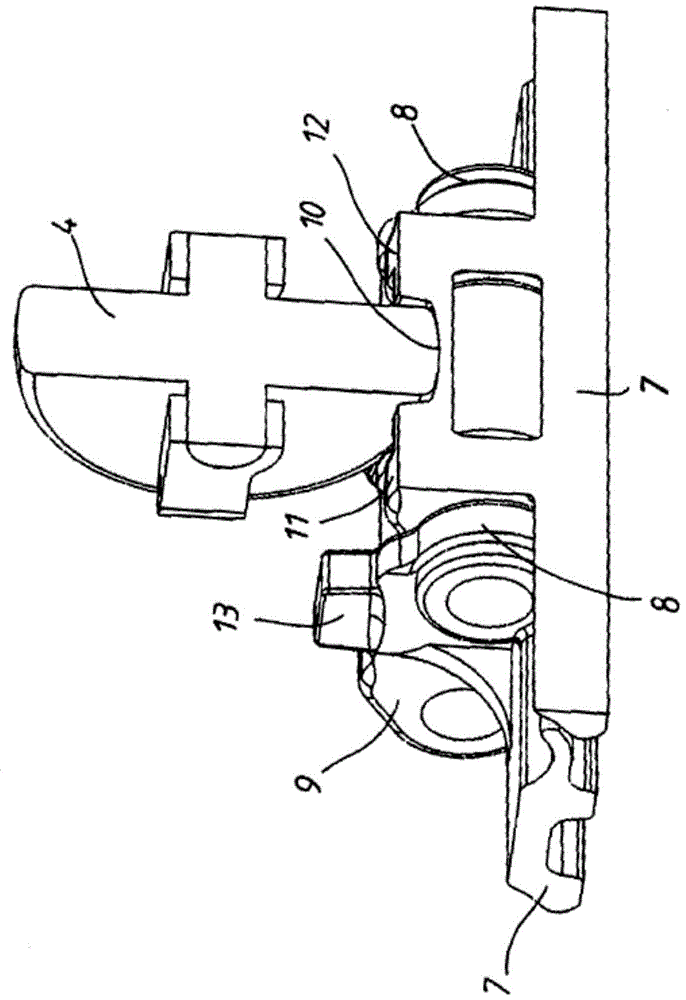

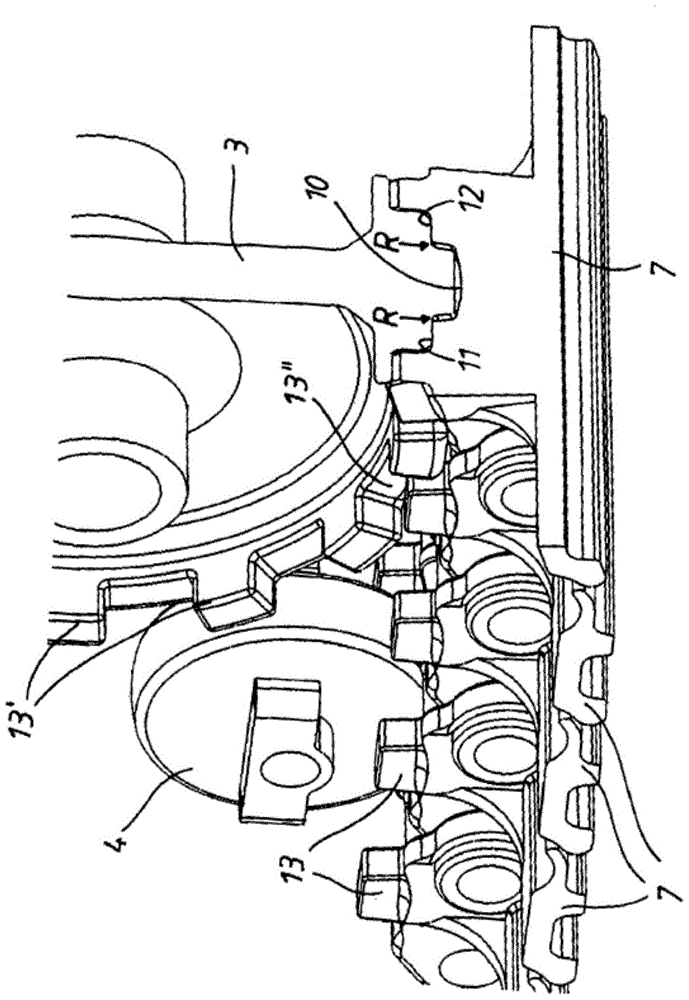

[0033] figure 2 Track shoe 7 operatively connected to track wheel 4 is shown. Connection areas 8 , 9 for receiving additional track shoes 7 can be seen. It can be seen in said figure that the track wheels 4 roll on an associated running surface 10 , which has a rectilinearly extending contour. Further running surfaces 11 , 12 are provided outside the running surface 10 for the track rollers 4 and the carrier rollers 5 , that is to say above the running surface 10 . Track shoe 7 has sprocket 13, and described sprocket is around driving wheel 3 ( figure 1 ) engages correspondingly provided tooth profile on drive wheel 3 when turning ( image 3 )middle. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com