Asymmetrical tooth profile chain two-phase transmission system

A transmission system, asymmetric technology, applied in the field of mechanical transmission, can solve the problems of low chain transmission capacity, skip teeth, large vibration, etc., to reduce the polygon effect, reduce vibration and shock, and enhance the transmission capacity of heavy loads. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

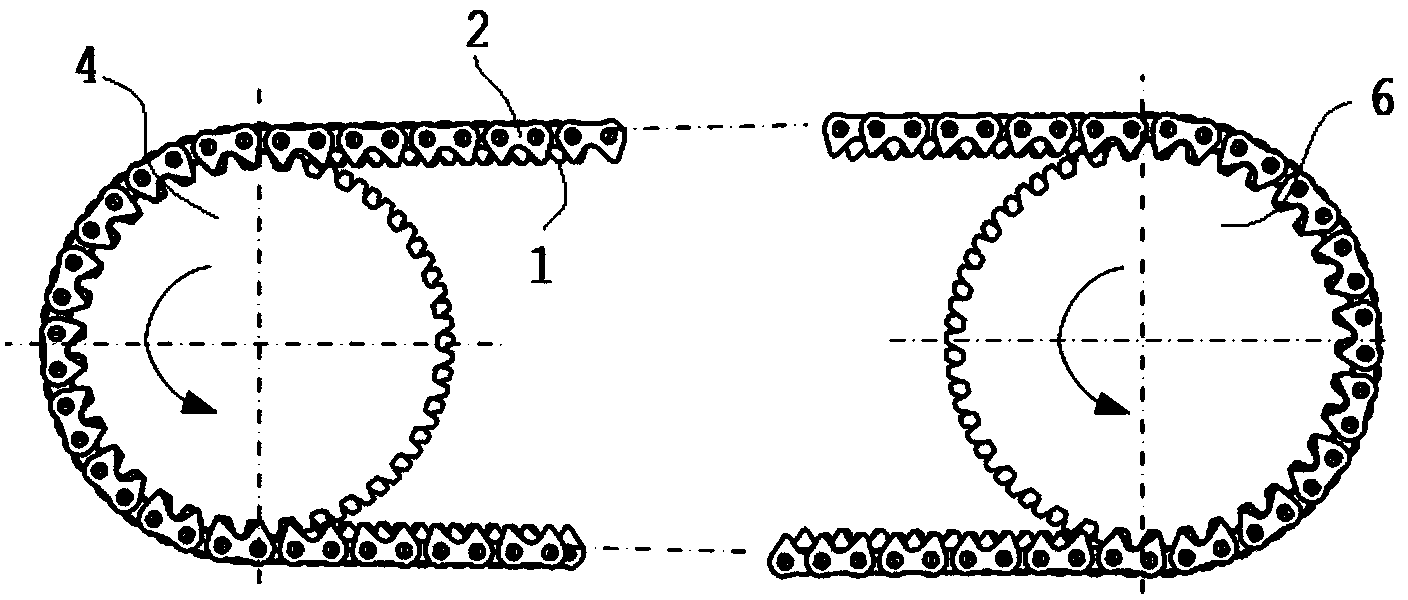

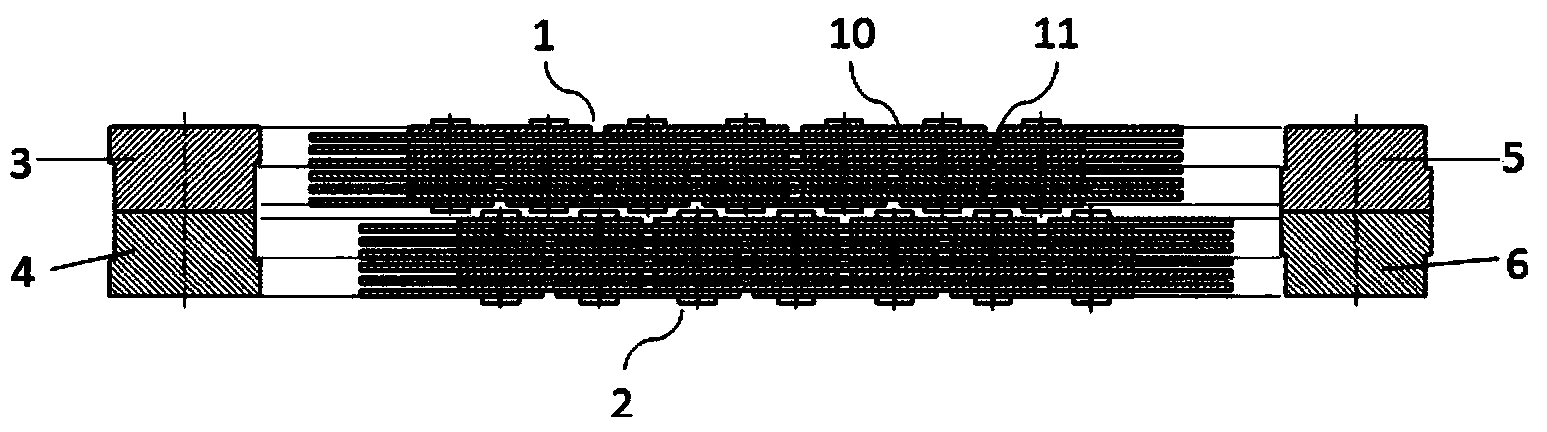

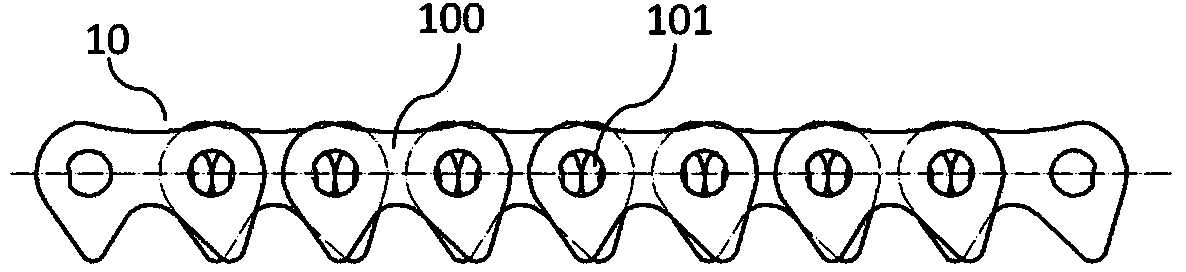

[0034] combine figure 1 and figure 2 , is a schematic diagram of the overall structure of the present invention, it can be seen that a kind of asymmetrical toothed chain two-phase transmission system of the present invention consists of the first hanging chain 1, the second hanging chain 2, the first driving sprocket 3, and the second driving sprocket 4 , the first driven sprocket 5 and the second driven sprocket 6, wherein the first driving sprocket 3, the first driven sprocket 5 and the first hanging chain 1 mesh with each other to form the first single Phase transmission system, the second driving sprocket 4, the second driven sprocket 6 and the second hanging chain 2 mesh with each other to form a second single-phase transmission system;

[0035] When installing, the difference between the first driving sprocket 3 and the second driving sprocket 4 is half a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com