Chain conveyor with adjustable distance between axes

A conveyor and pitch technology, applied in the direction of conveyor, transportation and packaging, packaging, etc., can solve the problem that the drive is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

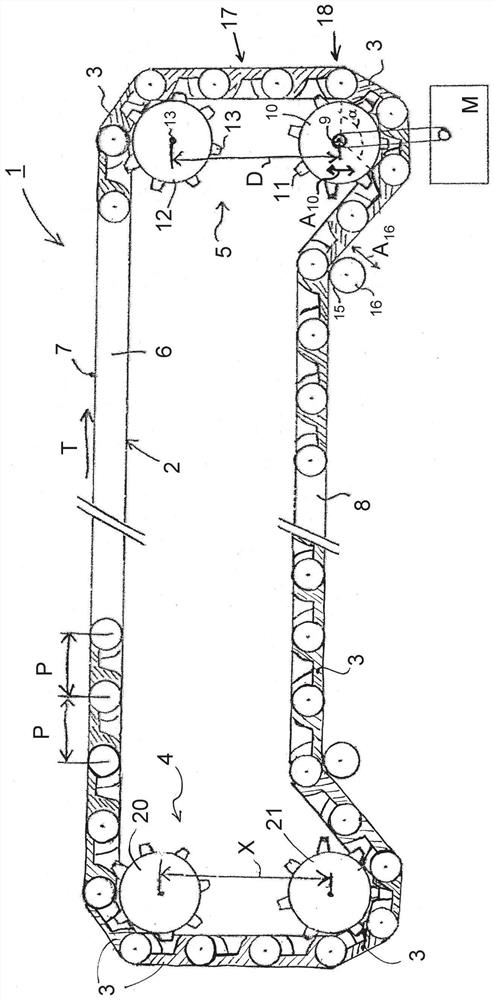

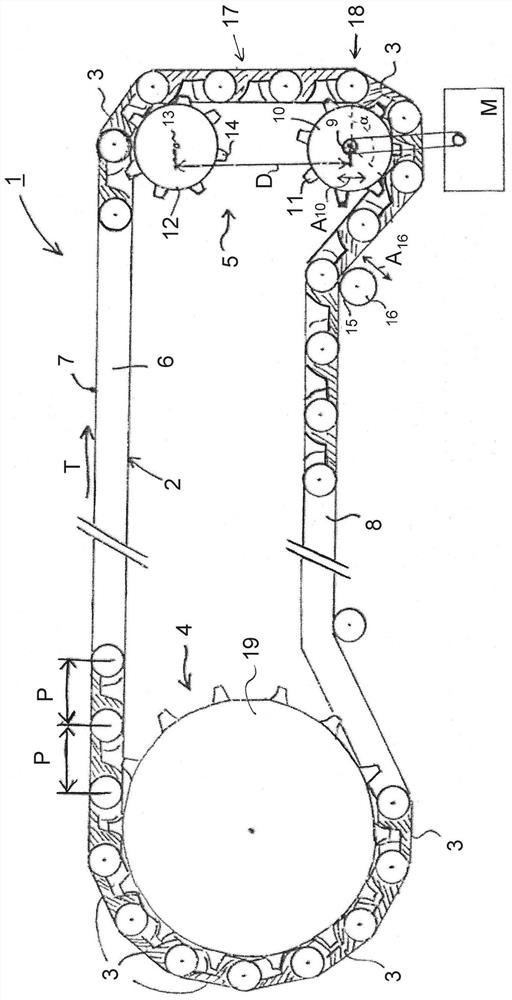

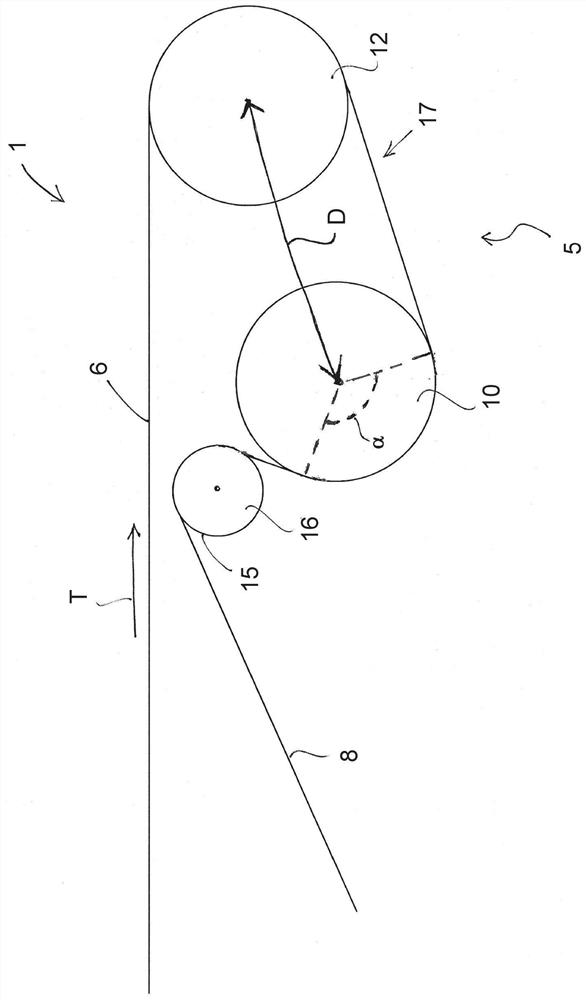

[0021]In the figures, a schematic cross-sectional view of an embodiment of a modular conveyor 1 according to the invention is shown. The modular conveyor 1 comprises a conveyor mat or conveyor chain 2 , in particular a substantially plastic conveyor mat or conveyor chain, for conveying products in the conveying direction T. The conveyor mat 2 or conveyor chain 2 comprises a succession of modules 3 or segments 3 , in particular substantially plastic modules 3 , which follow one another in the conveying direction T. Said modules 3 are hinged together forming an endless loop in a hitherto known manner. Viewed in the transport direction T, the modules 3 are each provided with hinge loops at their front and rear sides, wherein the hinge loops of successive modules 3 in the transport direction T cooperate and are connected by means of hinges extending transversely to the transport direction T. Pin connection. The hinge ring at the front side of the module is positioned at a pitch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com