Chain transmission and chain

A technology of chain transmission and driving device, applied in the direction of transmission device, gear transmission device, transmission chain, etc., can solve the problems of mechanical friction loss, high wear of chains and guide parts, shortening the service life of chains and guide parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that preferred embodiments of the invention are schematically shown in the drawings, but these embodiments are only non-limiting examples. In the drawings, the same or corresponding parts are denoted by the same reference numerals.

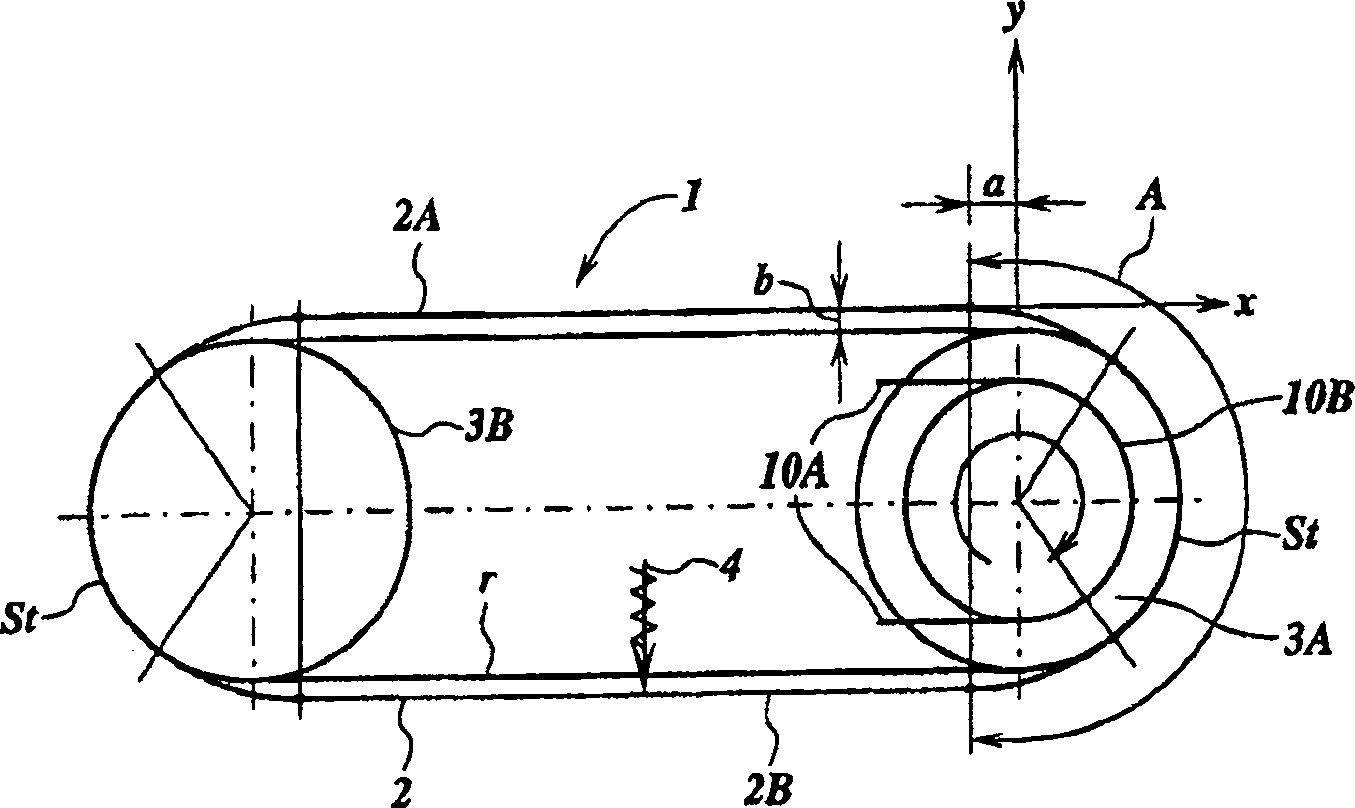

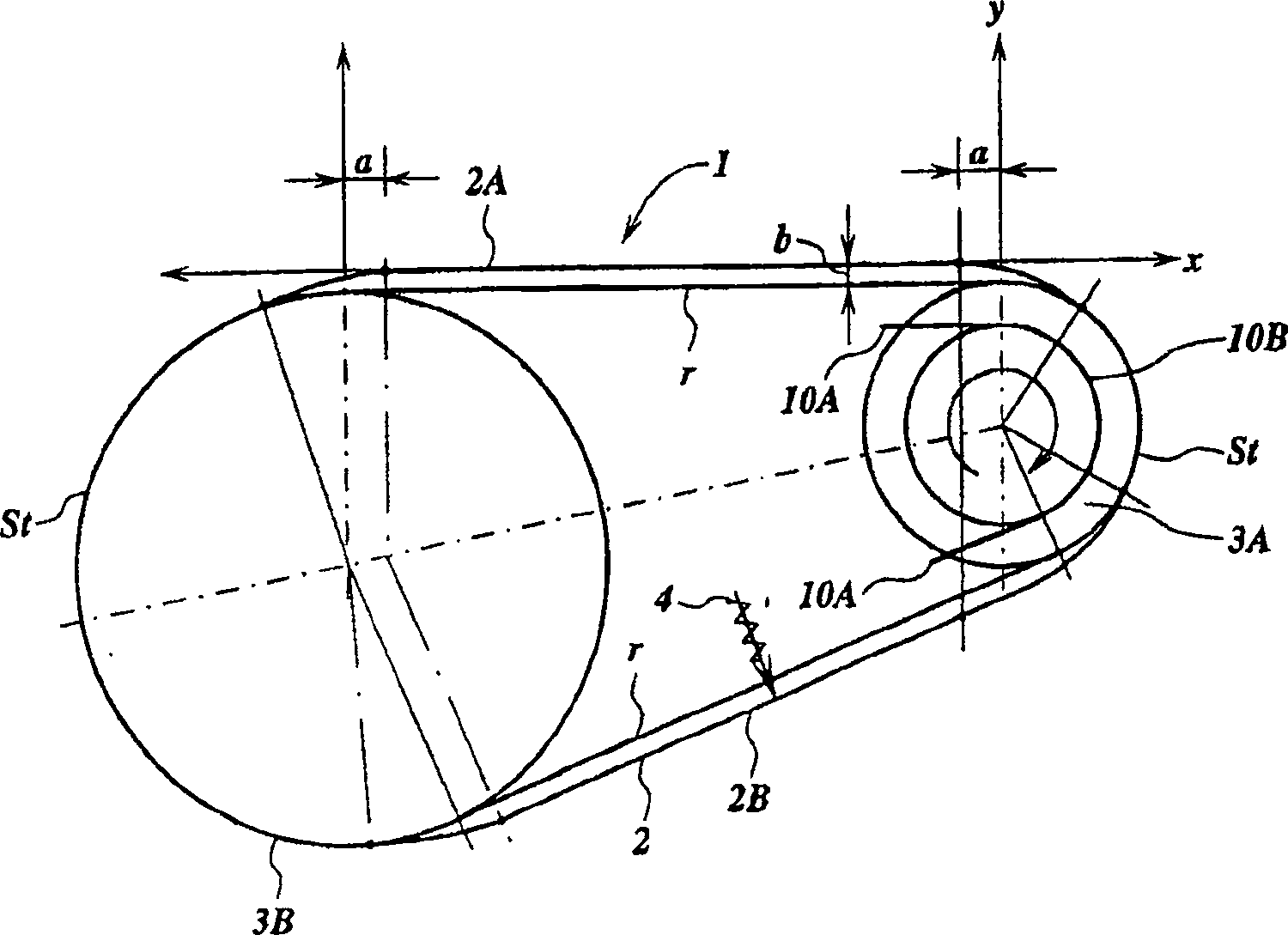

[0030] first refer to attached Figure 1A , which shows a chain drive 1 with a continuous chain 2 rotating around two sprockets 3A and 3B. The sprockets 3A and 3B are rotatably arranged and on their outer circumference are arranged teeth which, during use, interact with the continuous link 5 of the chain 2 on the engagement portion. The engagement portion around the sprocket 3A is indicated generally by the letter A in FIG. 1 . The sprocket 3A forms a driving sprocket in this embodiment, and the sprocket 3B forms a driven sprocket. The transmission ratio between the sprockets 3A and 3B is independent of the rotational position of the sprocket 3 . In this illustrative example a gear ratio equal to 1 has been chosen, how...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com