Automobile running water tank assembly, automobile front body structure and automobile

A front body and water tank technology, which is applied to the upper structure, vehicle parts, upper structure sub-assembly, etc., can solve the problems of poor versatility of the water tank, and achieve the effect of light weight, weight reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

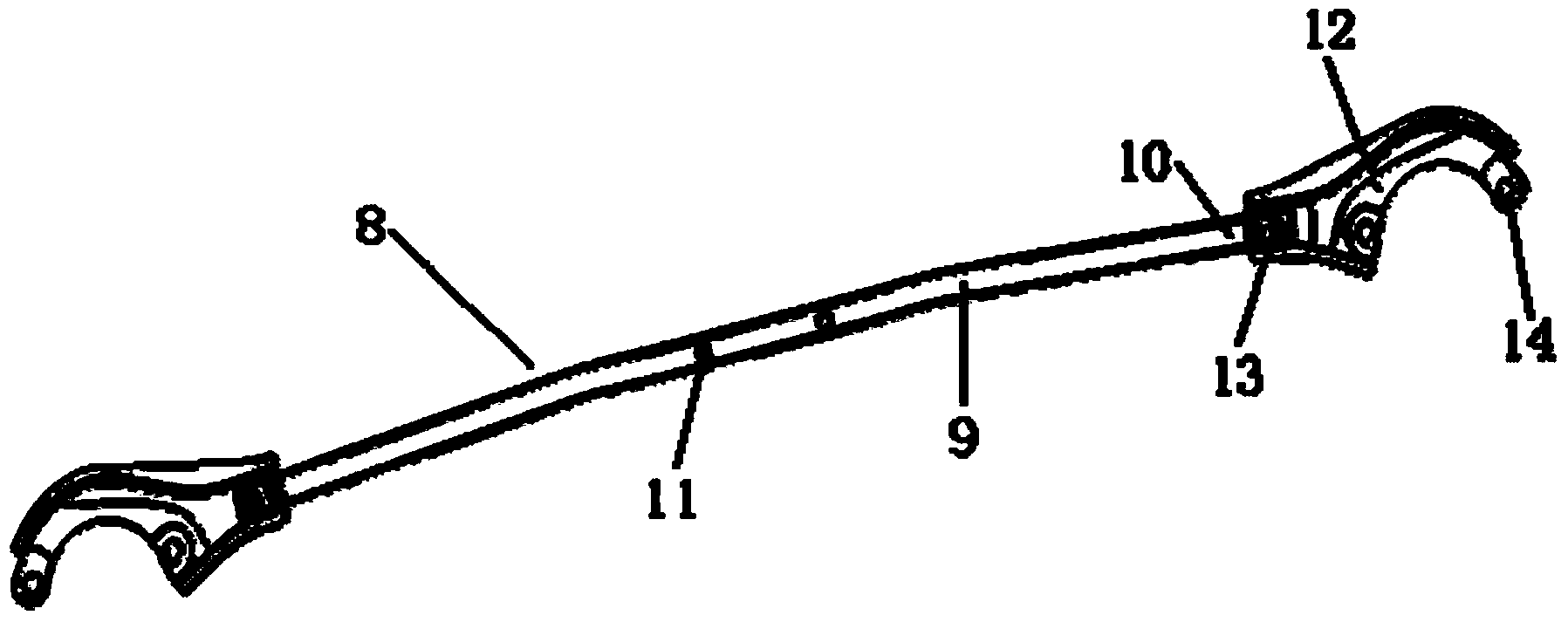

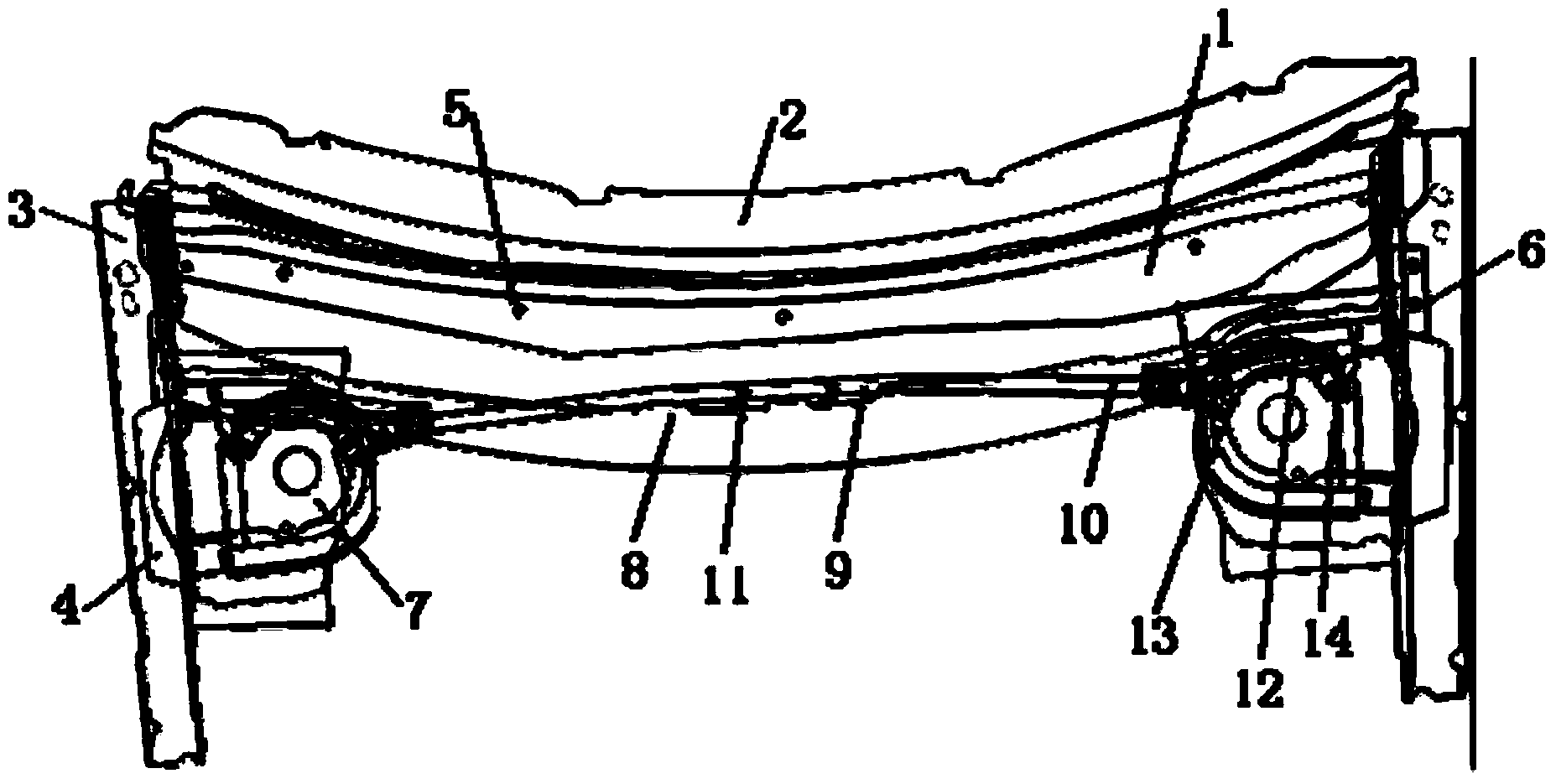

[0028] Such as figure 2 , 3 As shown, this embodiment provides an automobile water tank assembly, including a water tank 1, and a water tank reinforcement beam 8, the water tank reinforcement beam 8 includes a water tank reinforcement beam main body 9 and is arranged on the water tank reinforcement beam main body 9 two ends of the water tank reinforcement beam end 10, the water tank reinforcement beam main body 9 is connected with the water tank 1, and the two water tank reinforcement beam ends 10 are respectively connected with two of the front compartment of the car. The front shock absorber seat body 7 is connected.

[0029] The front shock absorber seat body 7 in this embodiment specifically adopts an exposed front shock absorber seat body.

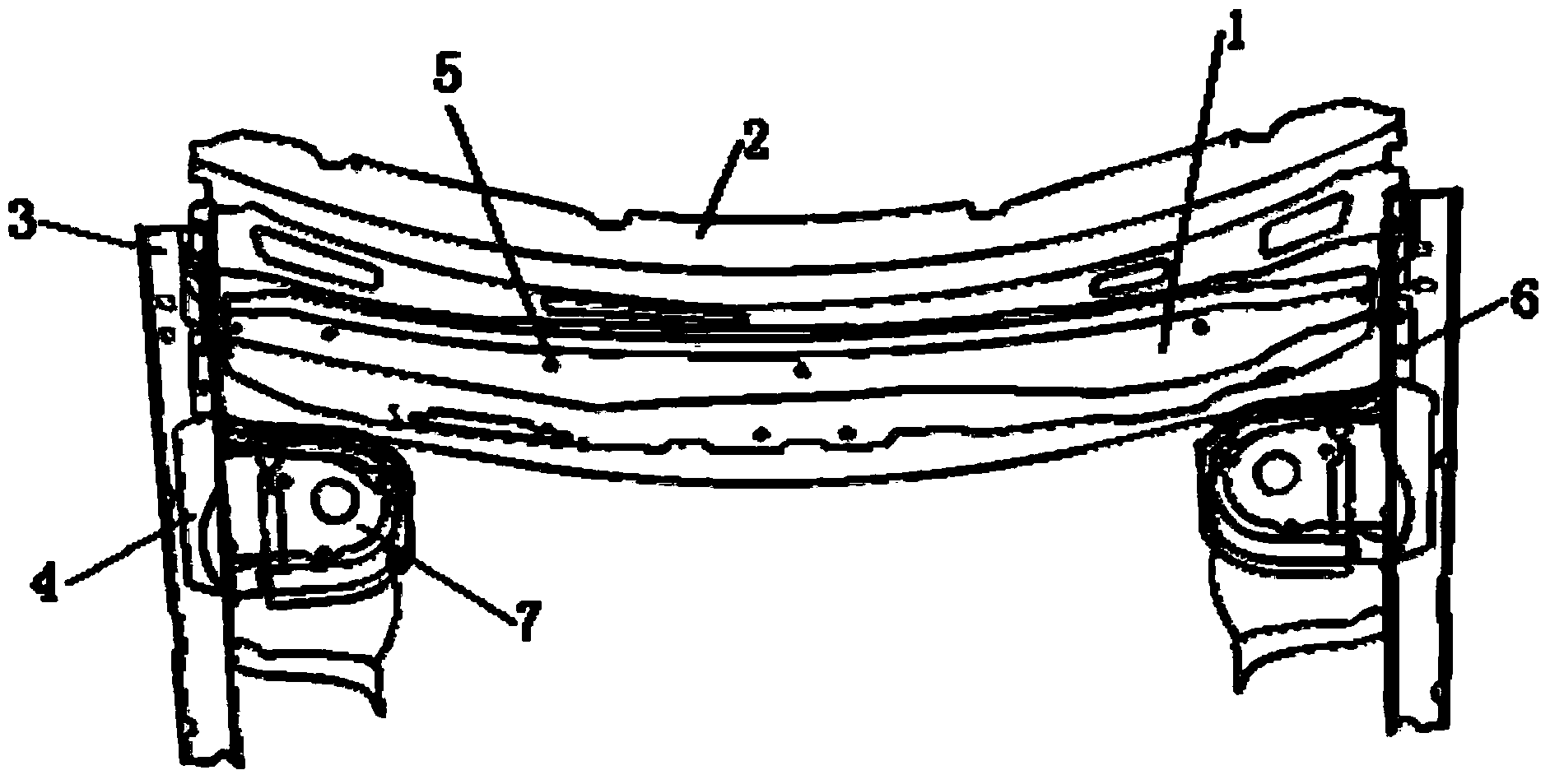

[0030] In this embodiment, the front compartment of the automobile includes a water tank assembly, a front windshield lower beam body 2 , a reinforcement plate body 3 on the front wheel house, a front shock absorber seat reinforcem...

Embodiment 2

[0047] This embodiment provides an automobile front body structure, including the automobile water tank assembly described in Embodiment 1.

Embodiment 3

[0049] This embodiment provides an automobile, including the automobile front body structure described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com