Thermoplastic elsatomer composition, and pneumatic tire using same

A technology of thermoplastic elastomer and composition, applied in the direction of no separate air cushion, special tire, tire parts, etc., can solve the problems of poor fatigue durability and achieve excellent fatigue durability and air barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

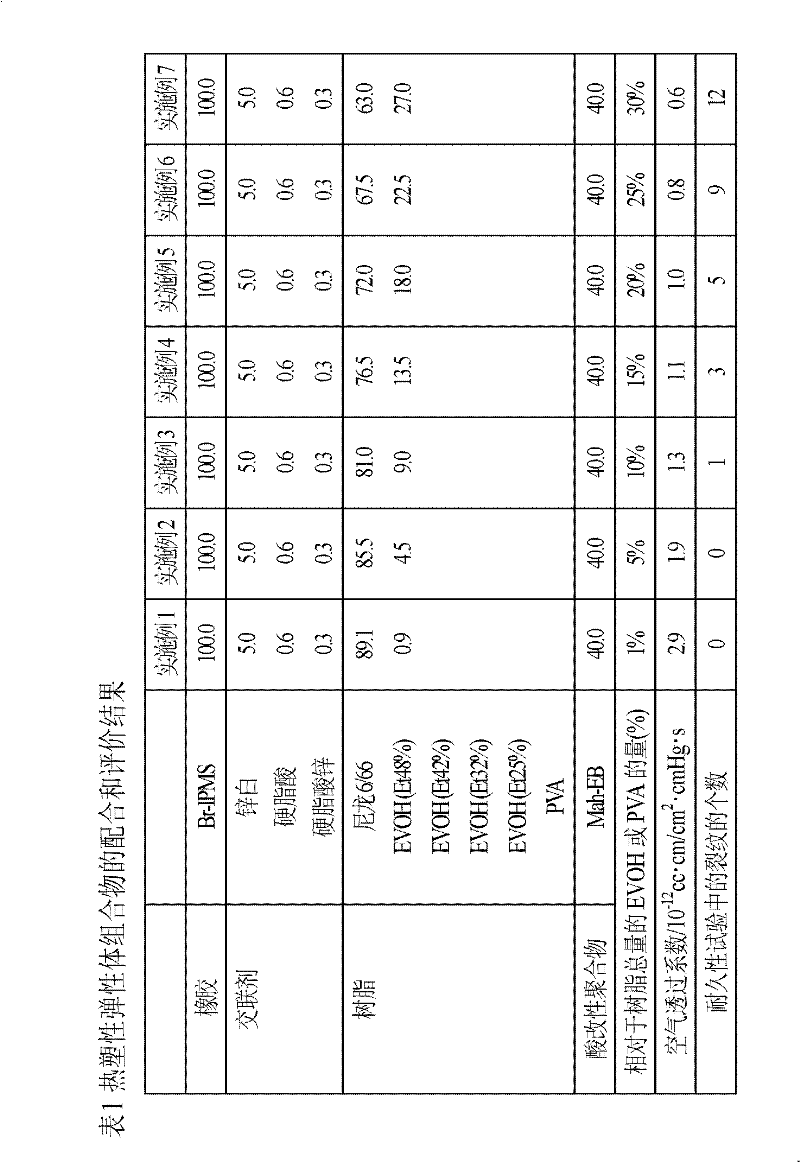

[0050] (1) Preparation of thermoplastic elastomer composition

[0051] As raw materials for the thermoplastic elastomer composition, the following were used.

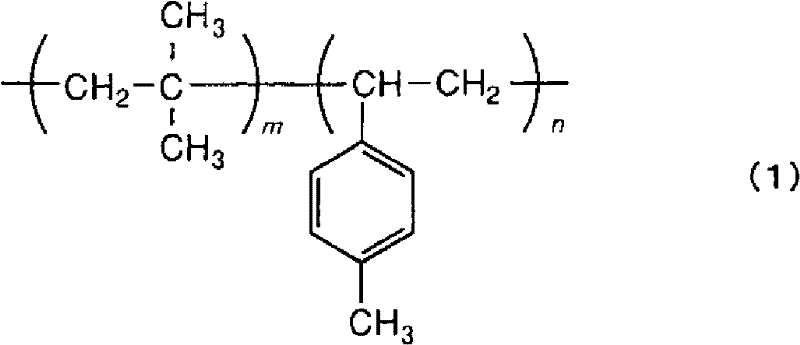

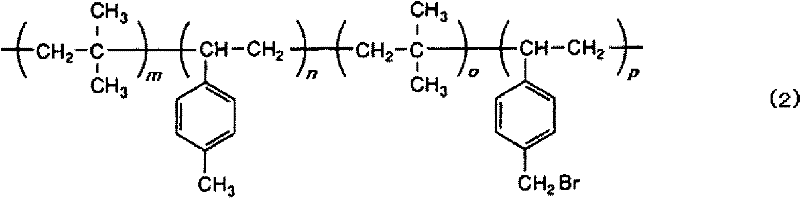

[0052] Br-IPMS: brominated isobutylene-p-methylstyrene copolymer "Exxpro" (registered trademark) MDX89-4 manufactured by ExxonMobil Chemical Company

[0053] Zinc oxide: 3 types of zinc oxide manufactured by Shodo Chemical Industry Co., Ltd.

[0054] Stearic acid: microbead stearic acid manufactured by NOF Corporation

[0055] Zinc stearate: Zinc stearate manufactured by Sakai Chemical Industry Co., Ltd.

[0056] Nylon 6 / 66: Ube Industries, Ltd. "UBE Nylon" 5013B

[0057] EVOH (Et48%): Nippon Synthetic Chemical Industry Co., Ltd. ethylene vinyl alcohol copolymer "SOARNOL" (registered trademark) H4815B (ethylene composition ratio 48 mol%, saponification degree 99% or more)

[0058] EVOH (Et42%): Nippon Gosei Chemical Industry Co., Ltd. ethylene vinyl alcohol copolymer "SOARNOL" (registered trademark) A4412B (ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com