Base sliding rail mechanism with hovering function

A slide rail and functional technology, applied in the field of base slide rail mechanism, to achieve the effect of ensuring consistency, high fatigue durability, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

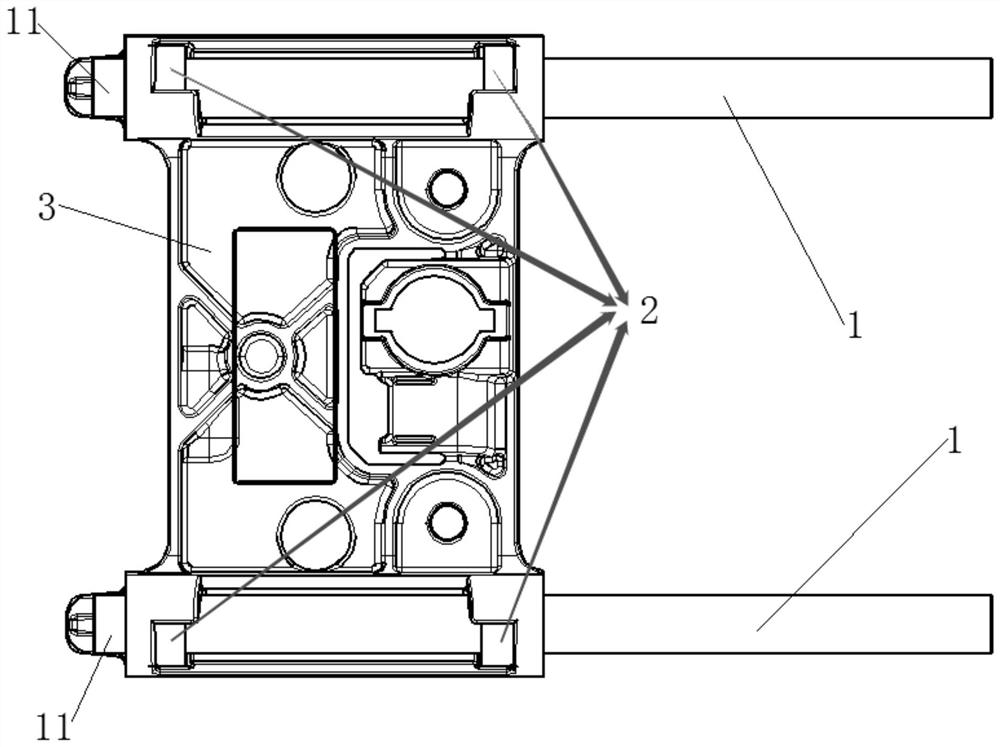

[0025] refer to figure 1 , this embodiment provides a base slide rail mechanism with a hovering function, including a base 3, a slide rail 1 and a friction ring 2, through holes are provided on both sides of the base 3, and the friction ring 2 is arranged on the base 3 In the through holes on both sides, and two friction rings 2 are arranged in the through holes on each side of the base 3, and are located at both ends of the base 3, and the slide rail 1 runs through the through holes of the base 3 and the friction rings in the through holes 2, and the slide rail 1 is in contact with the friction ring 2, the base 3 can move on the slide rail 1 through the friction ring 2, and the friction force generated between the slide rail 1 and the friction ring 2 can make the base 3 Hover on rail 1.

[0026] In this embodiment, the slide rail 1 is cylindrical, and the inner hole of the friction ring 2 is cylindrical. Both ends of the slide rail 1 are fixed on the external structure, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com