Workpiece clamping device and workpiece clamping method for cylindrical grinding machine

A cylindrical grinding machine and workpiece clamping technology, applied in the field of grinding and processing fixtures, can solve the problems of inconvenient clamping, difficult to ensure the coaxiality between the clamping axis and the workpiece axis, and low clamping efficiency, and achieve high clamping efficiency. , Simple structure, convenient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

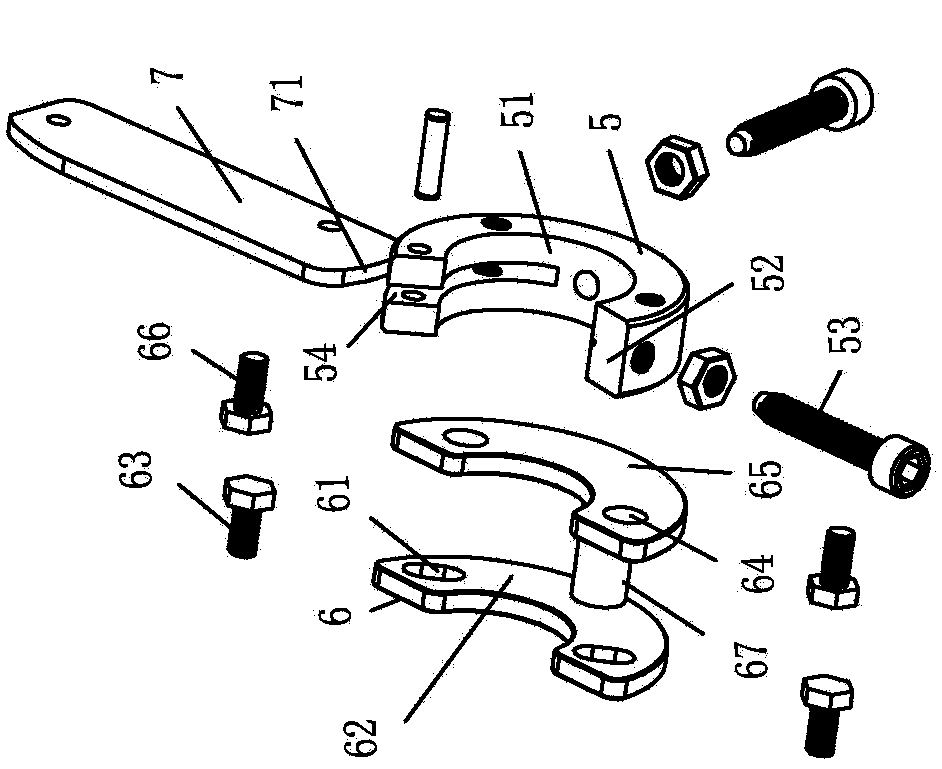

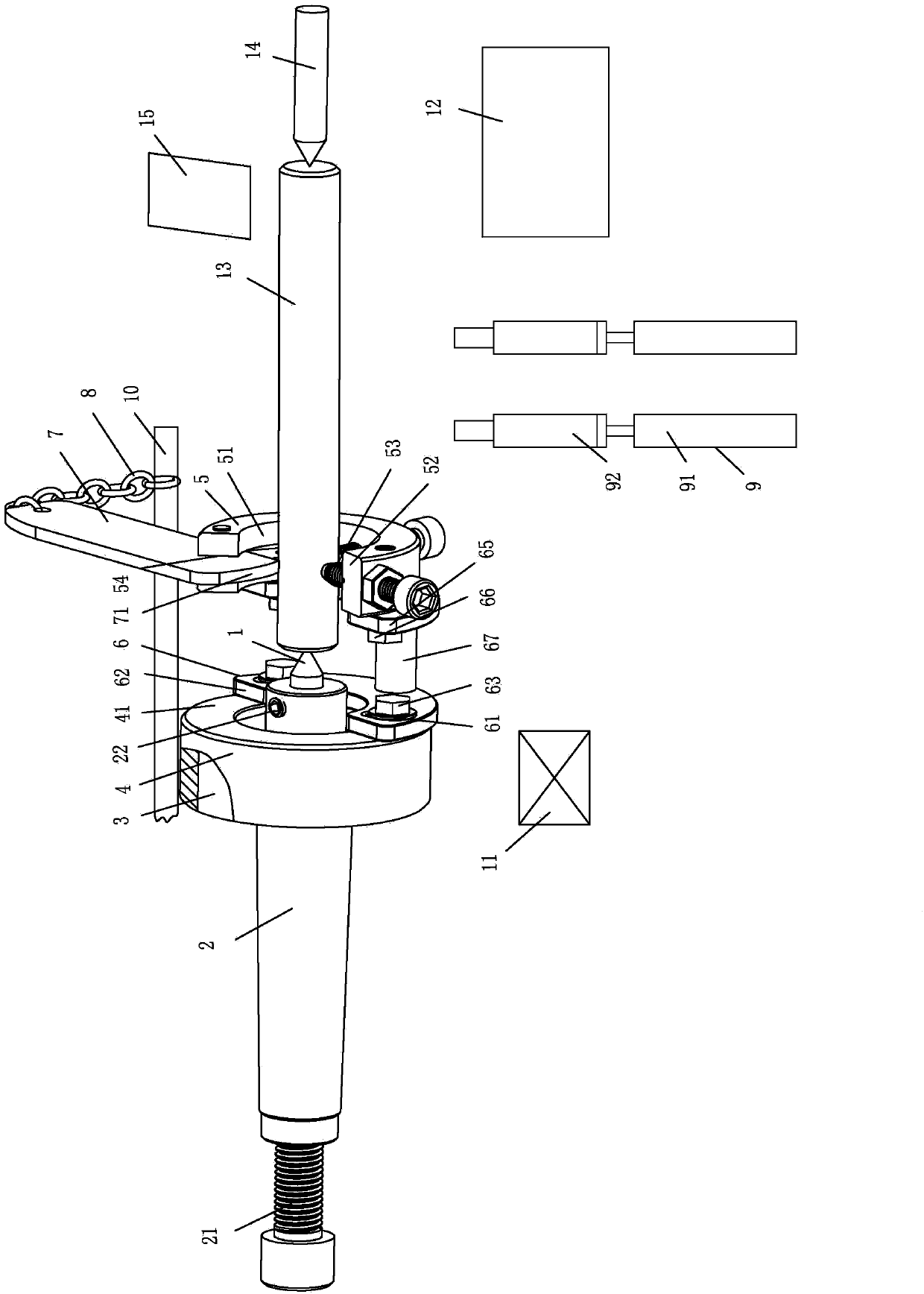

[0019] as attached figure 1 , attached figure 2 Shown: a workpiece clamping device for a cylindrical grinder, including a connecting handle 2 with a center hole (not shown in the drawings) at the front end, a headstock center point 1 whose rear end is located in the center hole, and is sleeved on the connecting handle 2 The one-way bearing 3 whose outer and inner rings are keyed to the connecting handle 2 is provided with a front retaining ring 41 and a bearing housing 4 connected with the outer ring of the one-way bearing 3, and a middle hole 51 is provided and is connected with the outer circumference and the middle hole respectively. The workpiece holder 5 of the opening 52 through which 51 penetrates, the adjustment assembly 6 connected to the workpiece holder 5 and the front retaining ring 41 respectively, and the inner end is provided with a clamp that clamps t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com