Method for setting up large box type steel structure permanent headframe during well drilling period

A technology for steel structures and derricks is applied in the field of erecting large-scale permanent derricks of steel structures, which can solve problems such as limitations and achieve the effects of improving the technological level and achieving significant economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

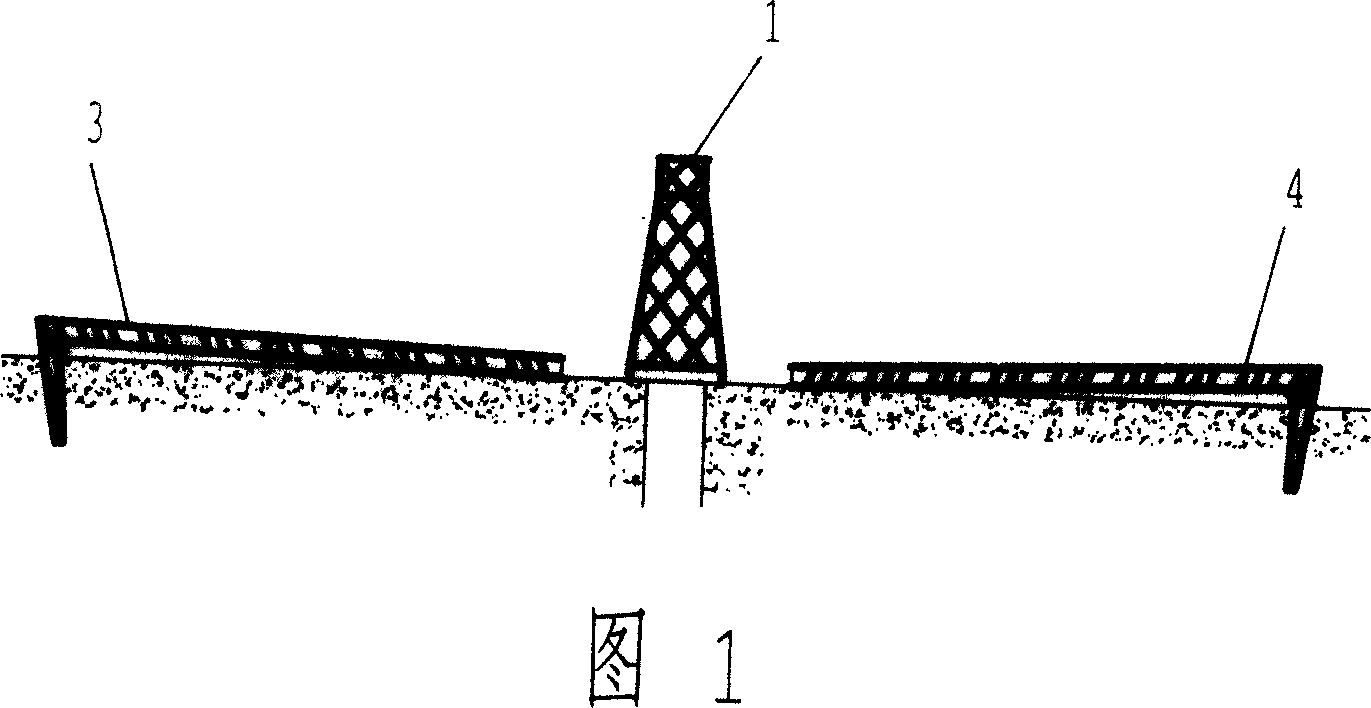

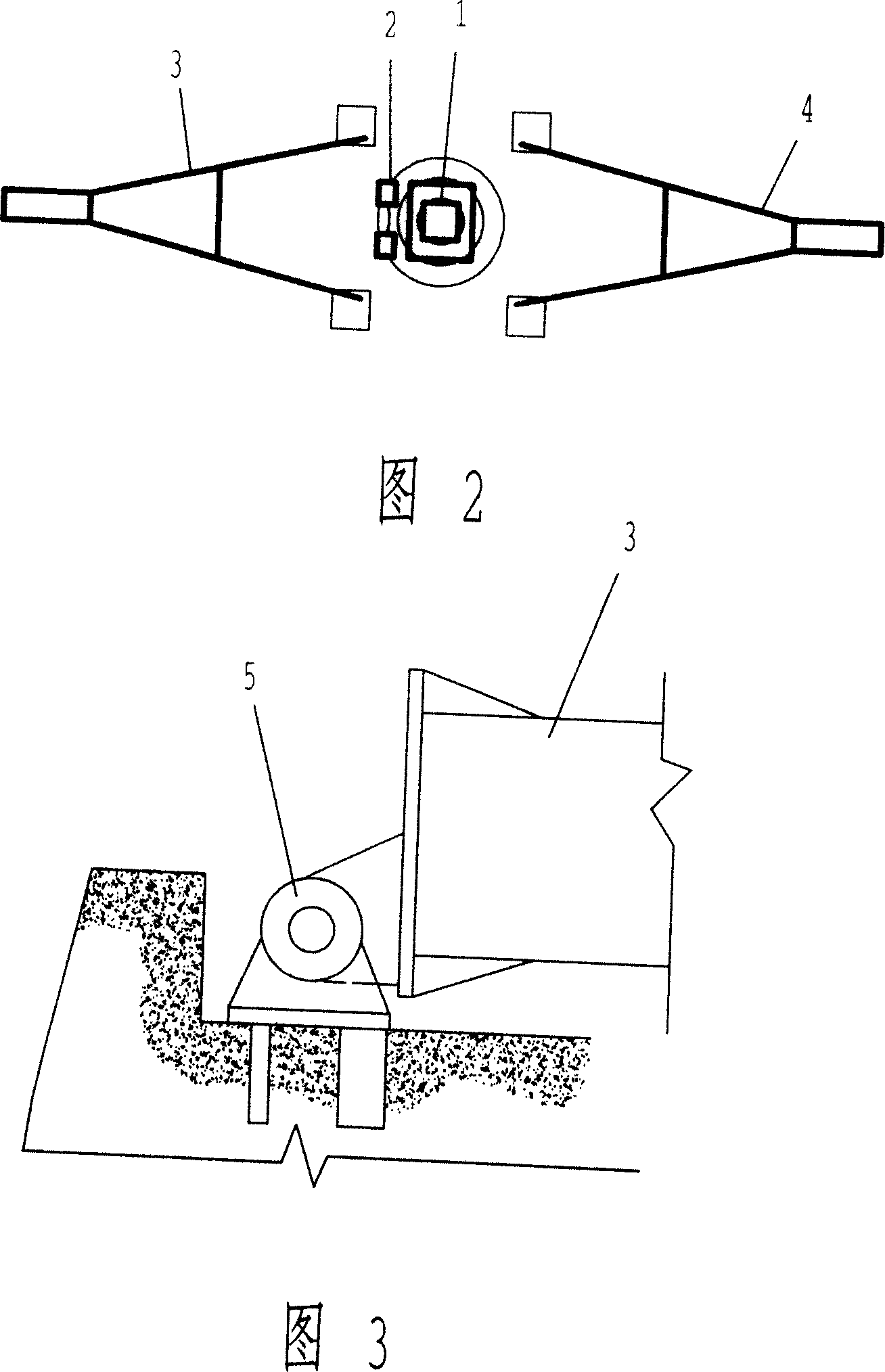

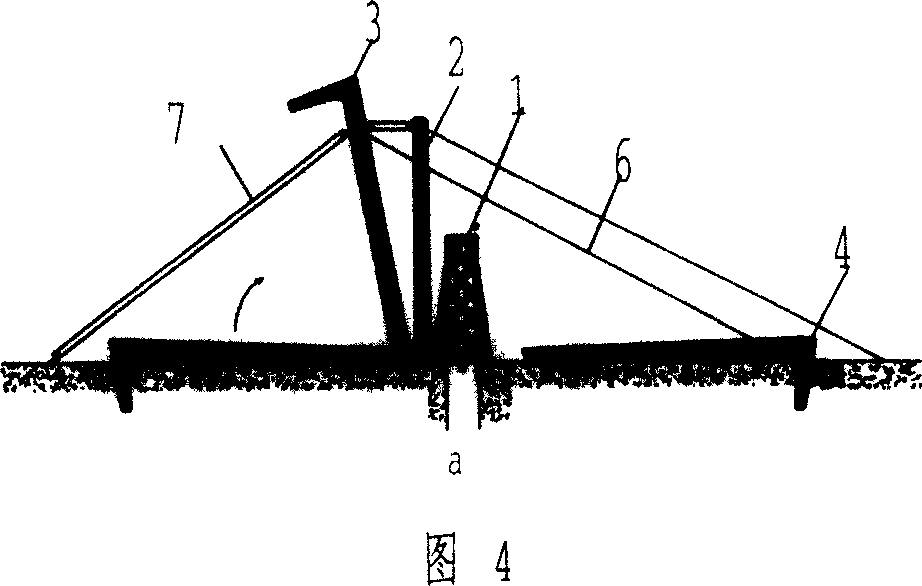

[0037] The present invention is a method for erecting a large-scale box-type steel structure permanent derrick during well drilling. It divides the large-scale box-type steel structure permanent derrick into two sector parts based on the centerline of the derrick, and assembles these two parts on the wellhead centerline respectively. Then the two parts are erected separately, closed in the air, and the top beam and other horizontal beams are welded to complete the erection of the derrick.

[0038] An example of the present invention is as follows:

[0039] Sinking derrick 1 is a pavilion-type derrick with four oblique braces. The root span of the four oblique braces of the derrick is 14m×14m. Well sinking derrick 1 is installed in the center of the shaft center line, and sinking hoisting winches and stabilizing cars are installed on the north and south sides of the well head. The permanent derrick to be erected is the opposite double lifting pavilion type derrick. The derrick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com