Gear rack coal bed methane drilling rig hoisting system

A rack-and-pinion and lifting system technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of difficult maintenance, low mechanical efficiency, and inability to pressurize the drill bit, so as to achieve easy installation and maintenance, safe and reliable work , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

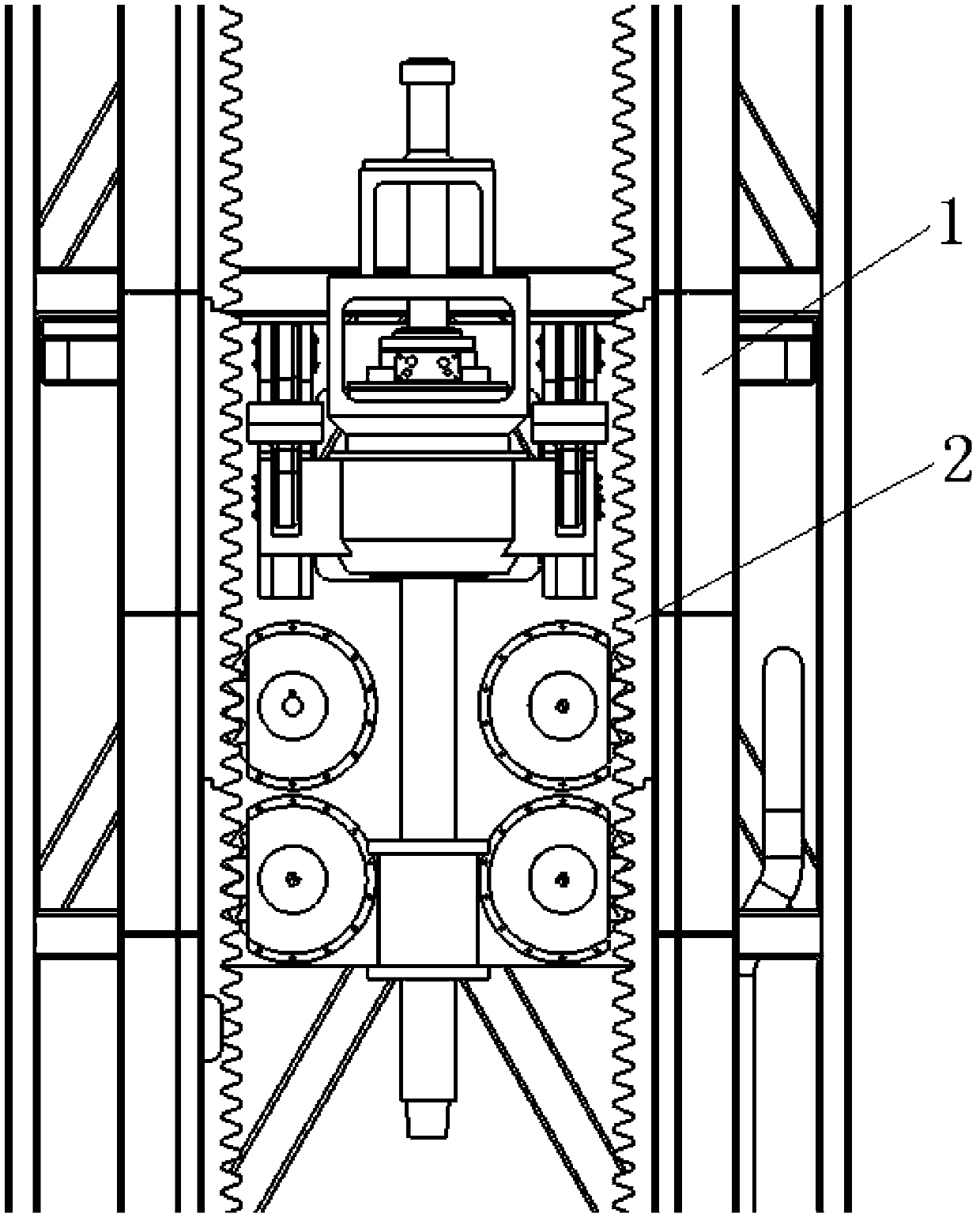

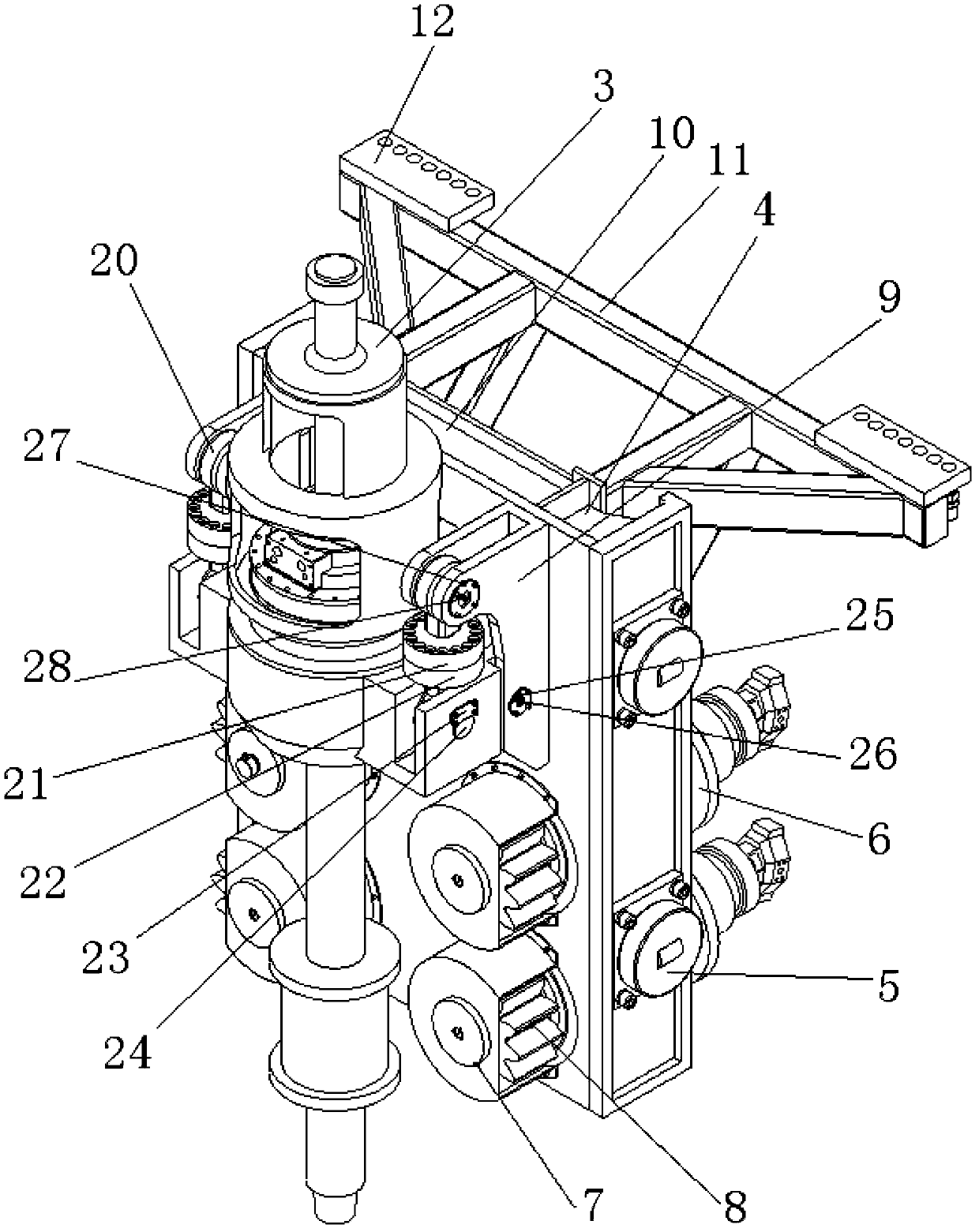

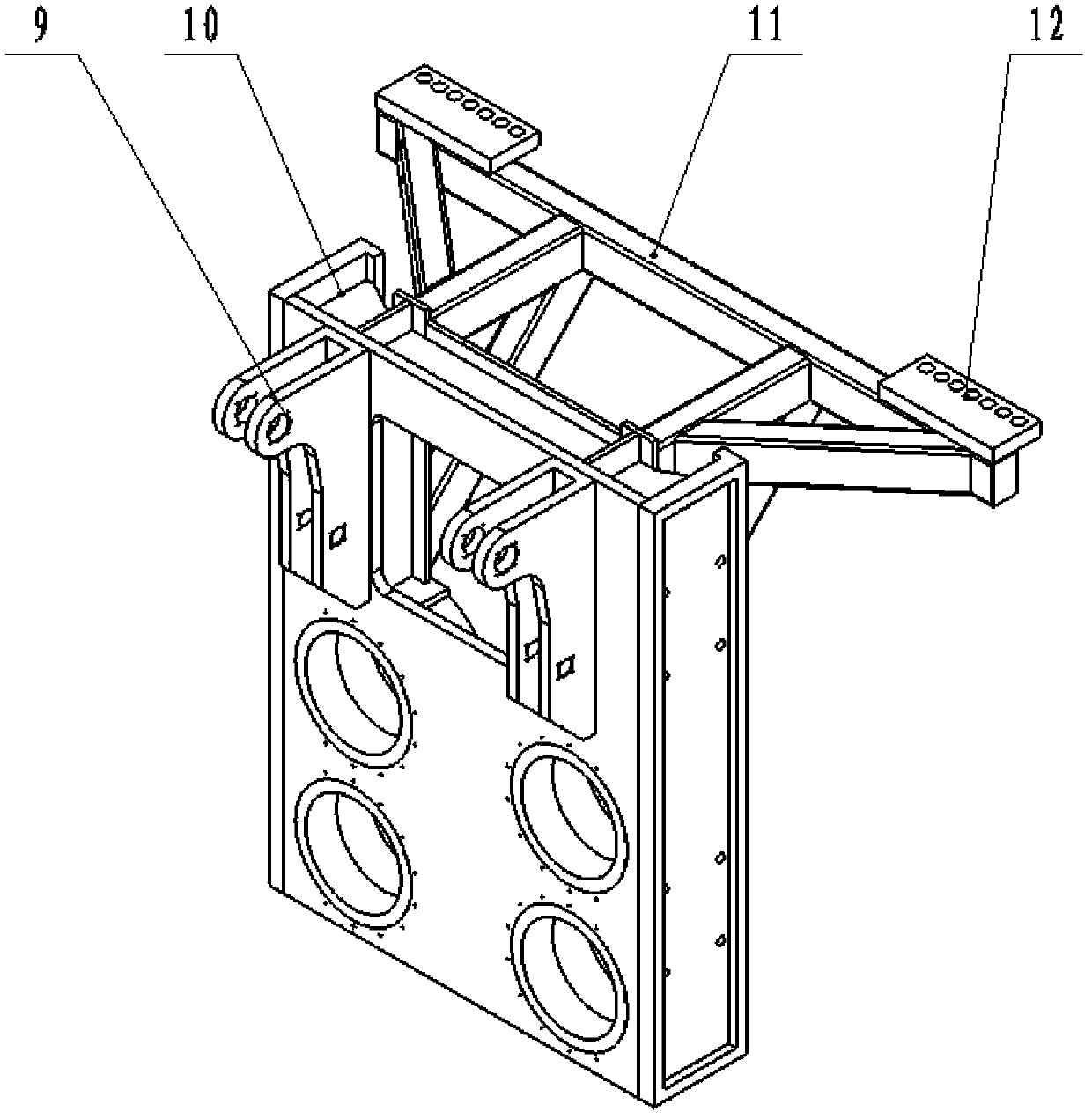

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a rack and pinion coalbed methane drilling rig lifting system includes a top drive device, a sliding device and a rack 2; the rack 2 is welded on the derrick 1 of the rack and pinion drilling rig, and the four cylindrical gears 8 on the sliding device Engaged with the rack 2; the sliding device is composed of a sliding car body 4, a guide pulley 5, a gear part, a hydraulic motor and a reducer 6, the sliding car body 4 includes a sliding frame 10, and a power faucet is welded on the sliding frame 10 for fixing The ear plate 9 and the lifting system valve plate frame 11, the lifting system valve plate 12 is welded on the lifting system valve plate frame 11, during the drilling operation, the lifting system valve plate 12 carries the hydraulic pipeline up and down with the lifting system Move; the guide pulley 5 is composed of a combination bearing 13 and a combination b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com