Autoamtic monitor method and device for safety of mining headframe

A safe, automatic and derrick technology, which is applied in surveying devices, earthwork drilling, surveying and navigation, etc., can solve the problems of difficult selection of measurement datum points, inconspicuous effects, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

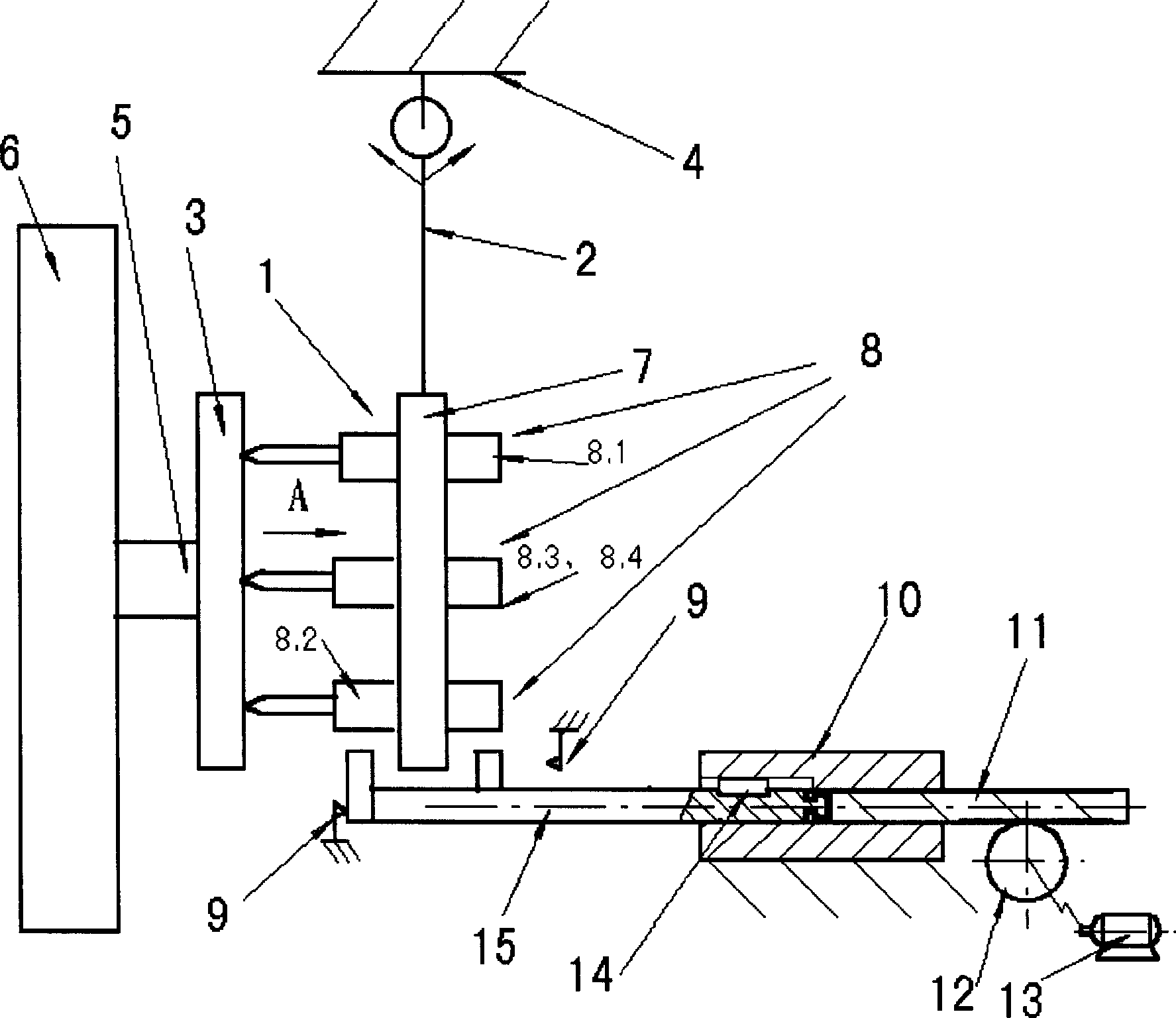

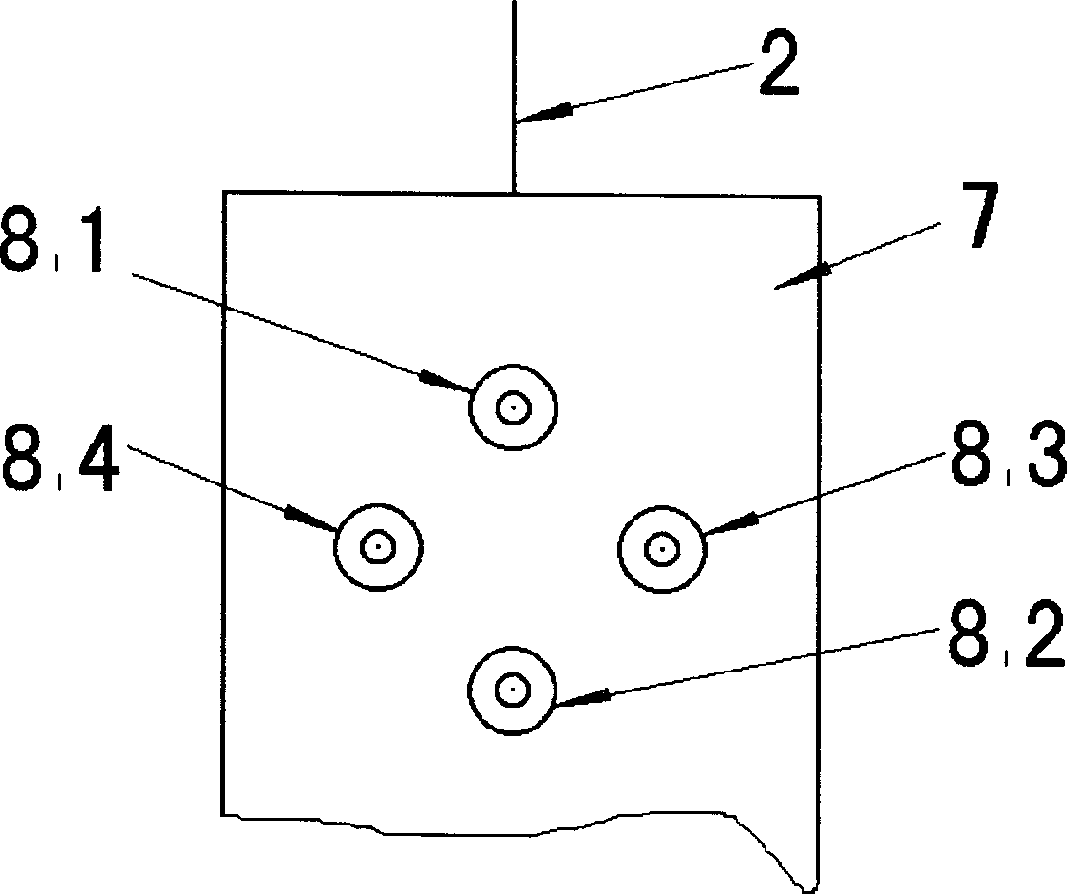

[0025] The present invention applies the basic principle of the sensor, based on the basic idea of converting tilt measurement into displacement measurement, and proposes the idea of a combined tilt sensor. The displacement sensor is used to realize tilt measurement. The sensor converts the sensed tilt into displacement, and outputs the corresponding The electrical signal is sent to the signal tuning circuit for filtering, amplification, shaping and isolation processing, and then the computer actually reflects the size and direction of the tilt of the derrick and the left and right sky wheels. If any tilt measurement value exceeds the preset value, the computer will automatically alarm.

[0026] Monitoring method of the present invention comprises the following steps:

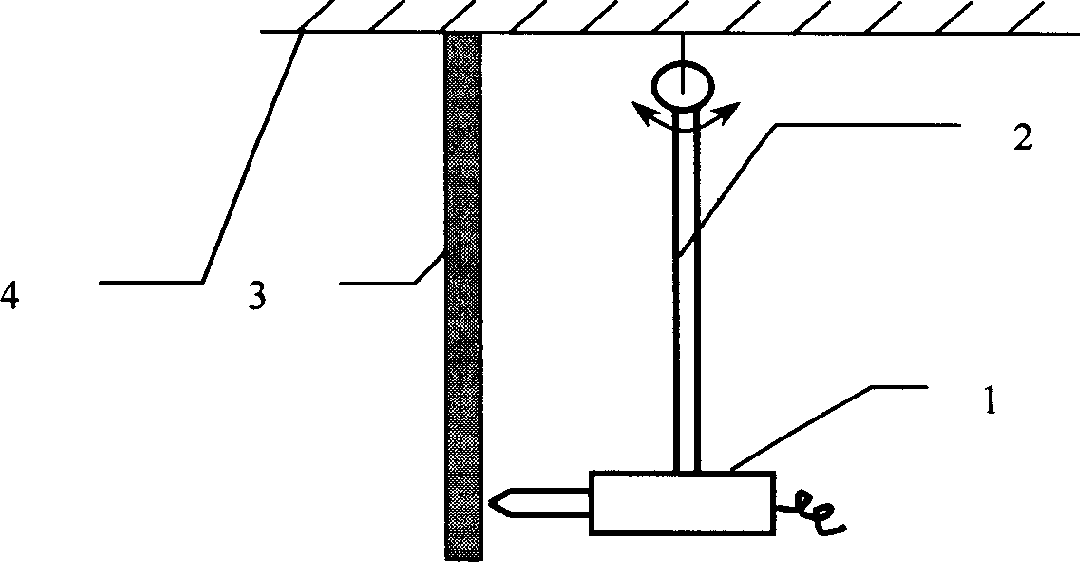

[0027] The gravity pendulum is installed on the derrick, the displacement sensor is installed on the gravity pendulum, and the displacement sensor and the gravity pendulum are in a vertical relationship. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com