Overhead hoisting and butt-joint method for box-type headframe

A derrick and hoisting technology, which is applied in the direction of drilling equipment, earthwork drilling, support devices, etc., can solve problems such as undiscovered solutions, and achieve the effects of shortening the well construction period, avoiding production stop loss, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

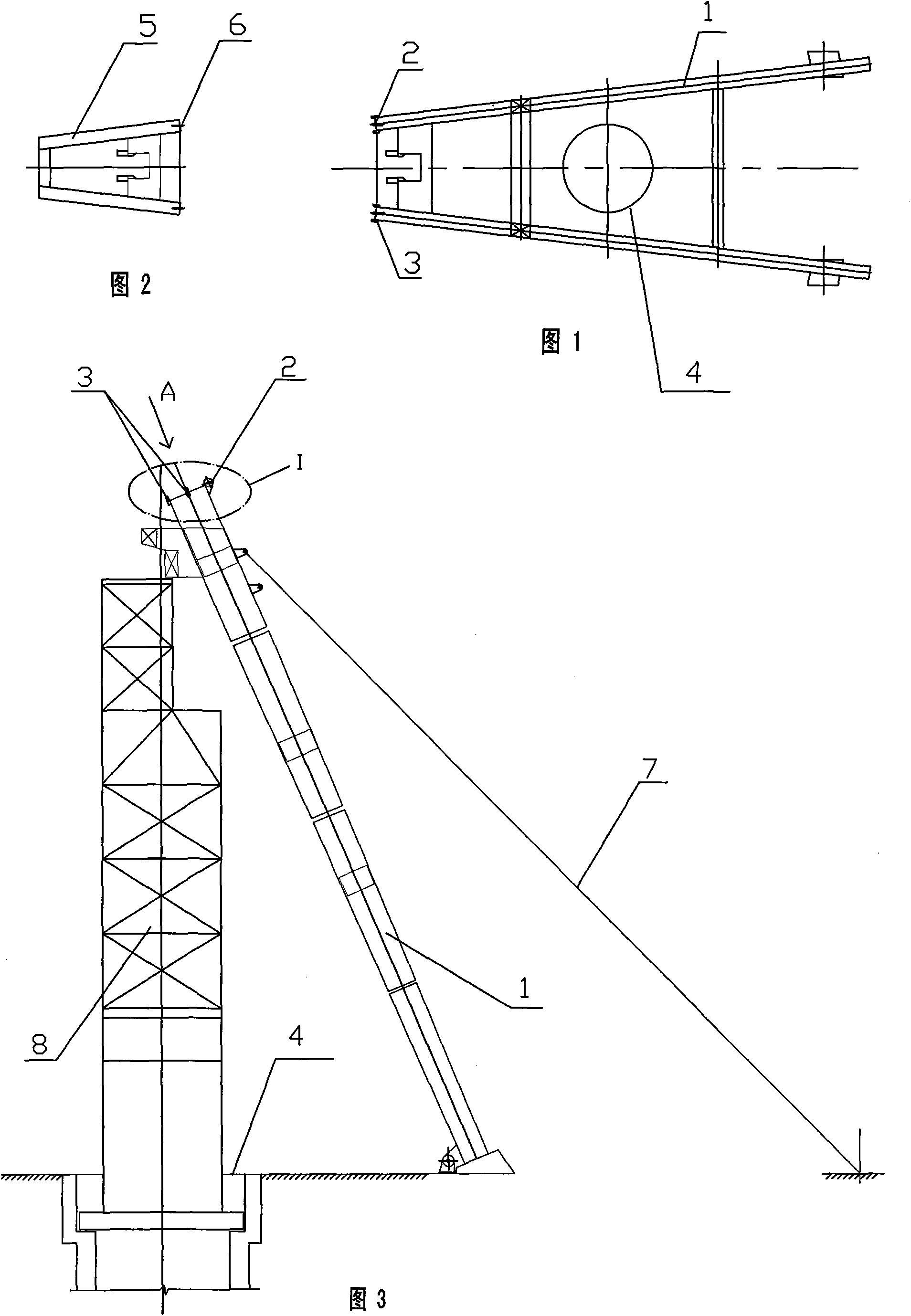

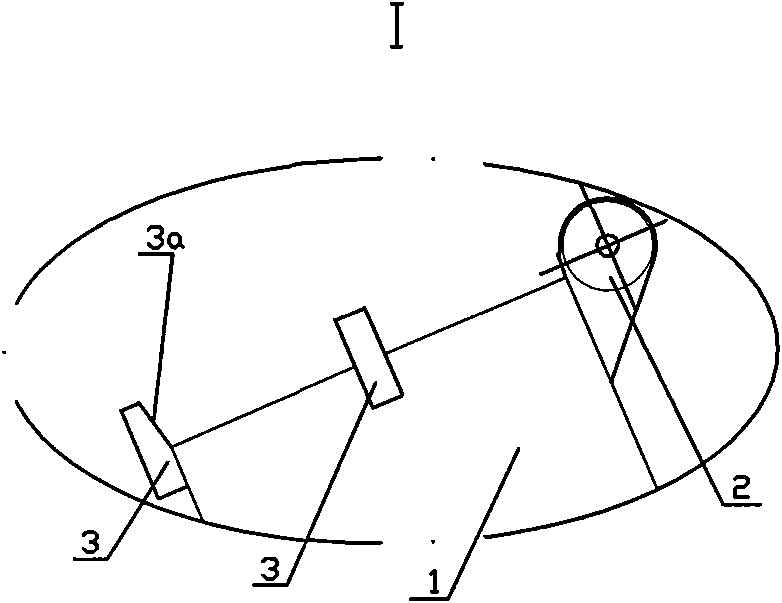

[0023] Such as figure 1 , figure 2 As shown, the box-shaped derrick is divided into two sections to manufacture because the site is too narrow to meet the overall assembly requirements of the derrick. figure 1 Shown is the main derrick 1, which is located at the center of the wellhead 4 during manufacture. The main derrick 1 end is provided with hinged seats 2 on one side and positioning blocks 3 on the other two sides. figure 2 Shown is the hoisting derrick 5 , the lower end surface of which is provided with hinged ears 6 to connect and cooperate with the hinged seat 2 .

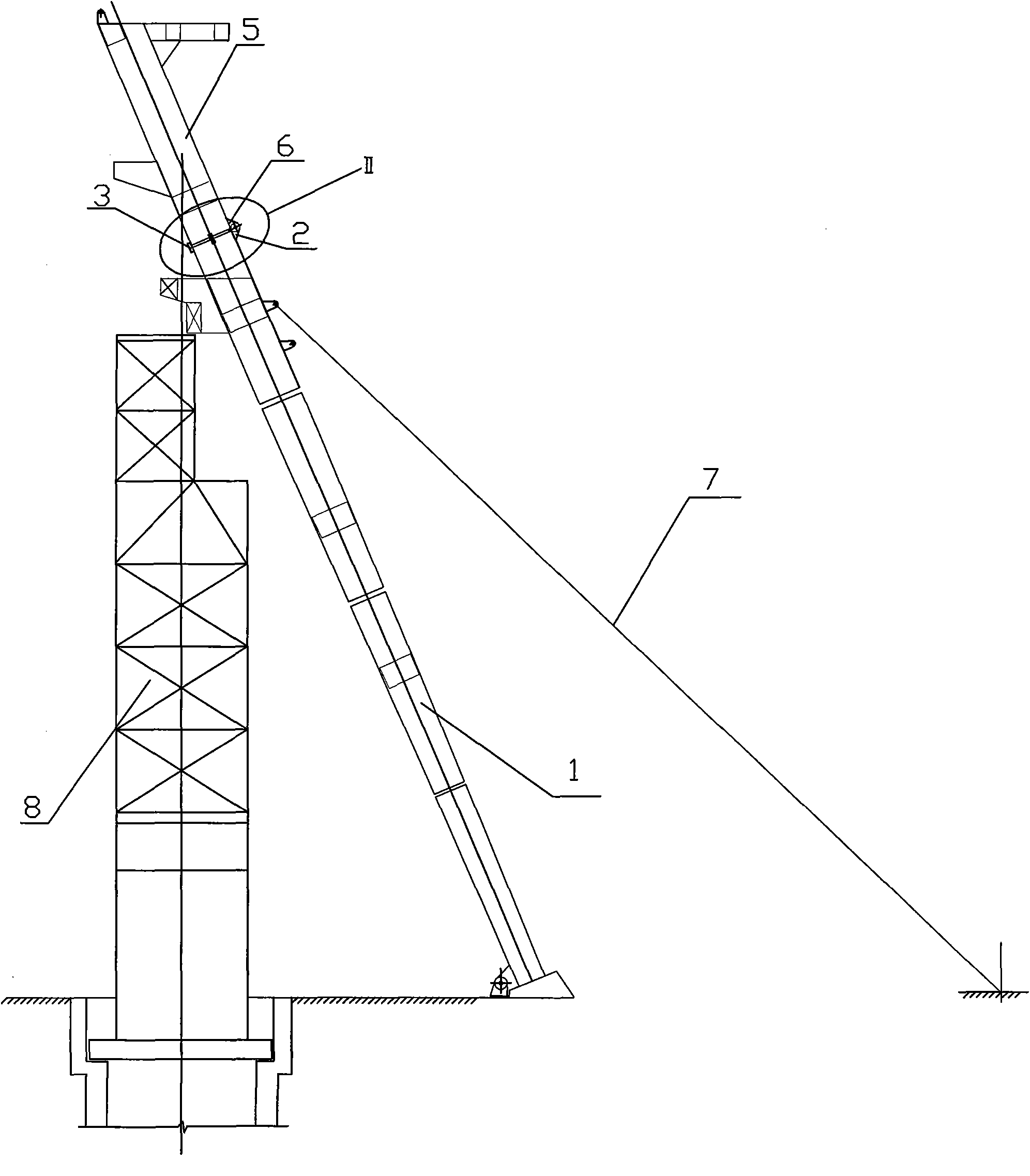

[0024] Such as image 3 As shown, the main derrick 1 is first pulled up with the main rope 7 and fixed after reaching a certain height and inclination; The installation of the wellhead stand and the main derrick is a conventional installation method.

[0025] The upper end of the main derrick 1 is box-shaped, one side is provided with a hinged seat 2, and the other side is provided with a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com