Top butt-joint type oil rig headframe

A docking, oil technology, applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problems of small moving length, safety accident of telescopic mechanism, large telescopic force, etc., and achieve flexible structure, high reliability, and installation force. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

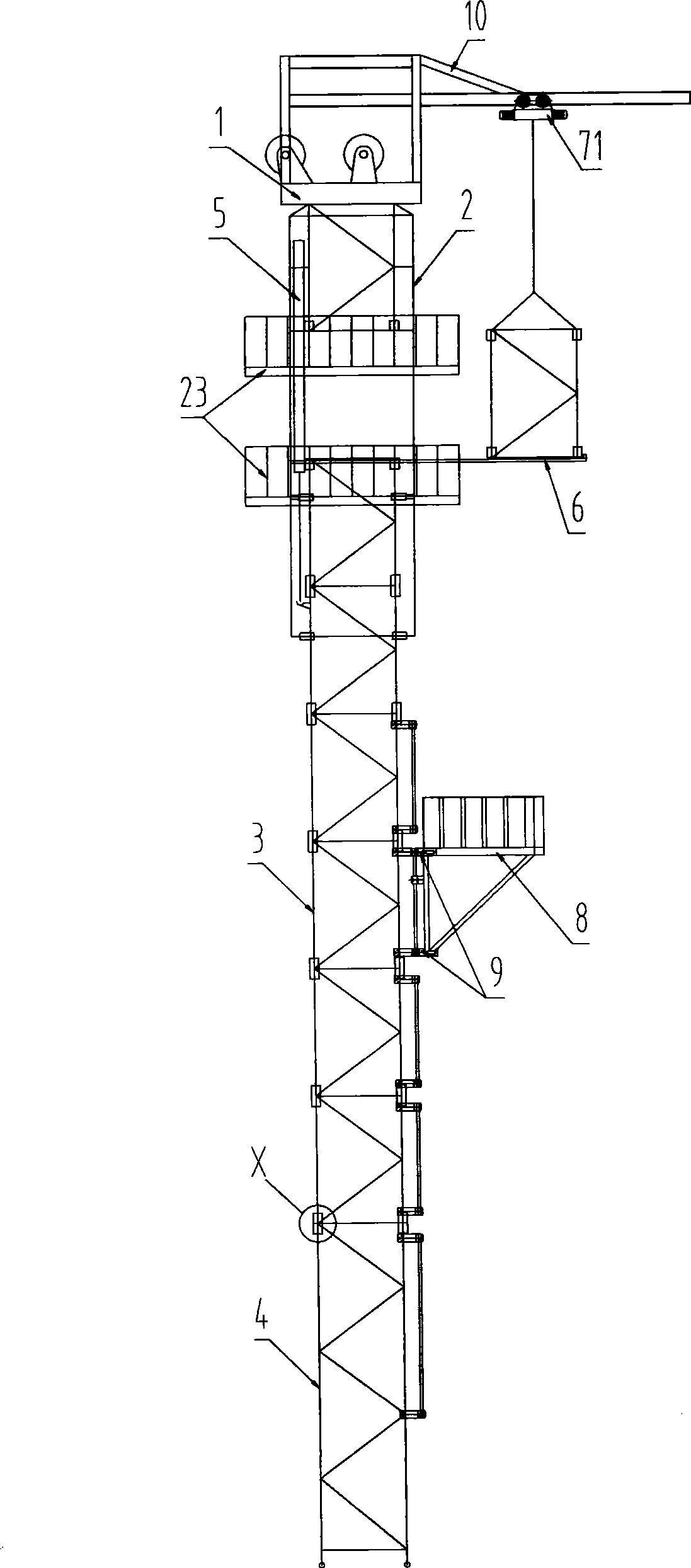

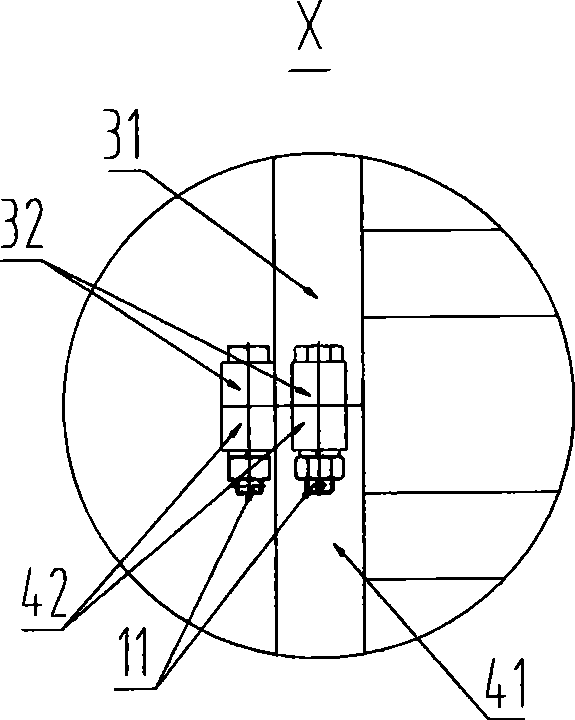

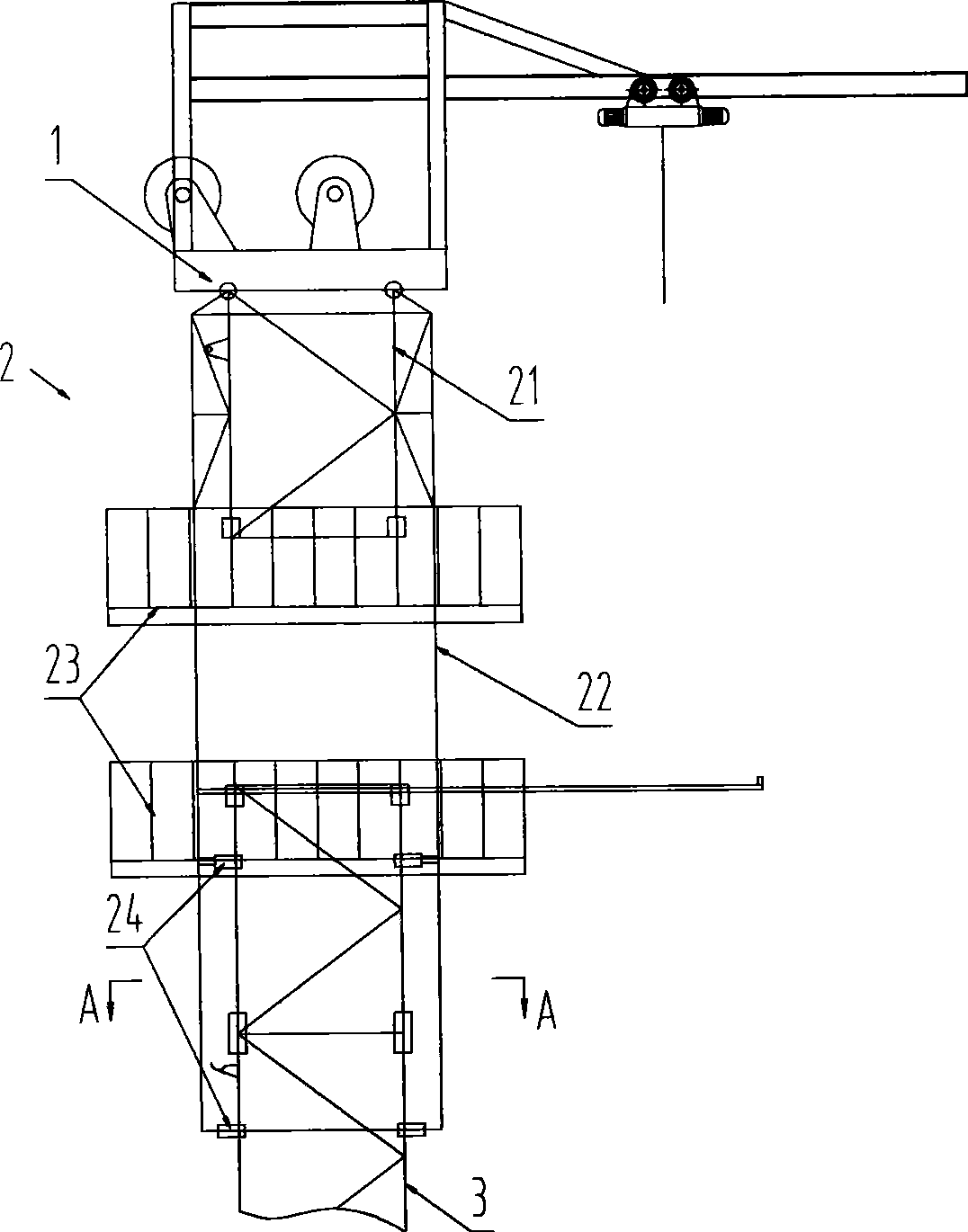

[0047] see first figure 1 , figure 2 , the derrick of the present invention is composed of crown block 1, upper section 2, several middle sections 3, lower section 4, upper telescopic mechanism 5, middle section movement and position limiting device 6, hoisting and transporting device, second-floor workbench 8, second-floor platform guiding movement and positioning Mechanism 9, crown block maintenance frame 10 and other necessary annexes of derrick such as working ladder, riser etc. are formed. The upper section 2, some middle sections 3, and the lower section 4 are all welded by four upright columns, diagonal braces, cross beams, and cross braces to form an upright, front-opening truss structure, and two side and one rear single-piece welded bolts in the known technology can also be used. Or pin-connected sub-assembly structure to facilitate transportation and hoisting. The lower section of the derrick can also be flexibly designed as a structure with a straight section at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com