Gear rack lifting drilling machine

A gear rack and drilling rig technology, applied in drilling equipment, earth-moving drilling, drilling equipment and methods, etc., can solve the realization and restriction of automatic operations such as precise automatic drilling, automatic discharge and transfer of drill pipes, etc. Process realization, no down pressure load and other problems, to achieve the effect of simple and lightweight base structure, improved safety and work efficiency, and reduced manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

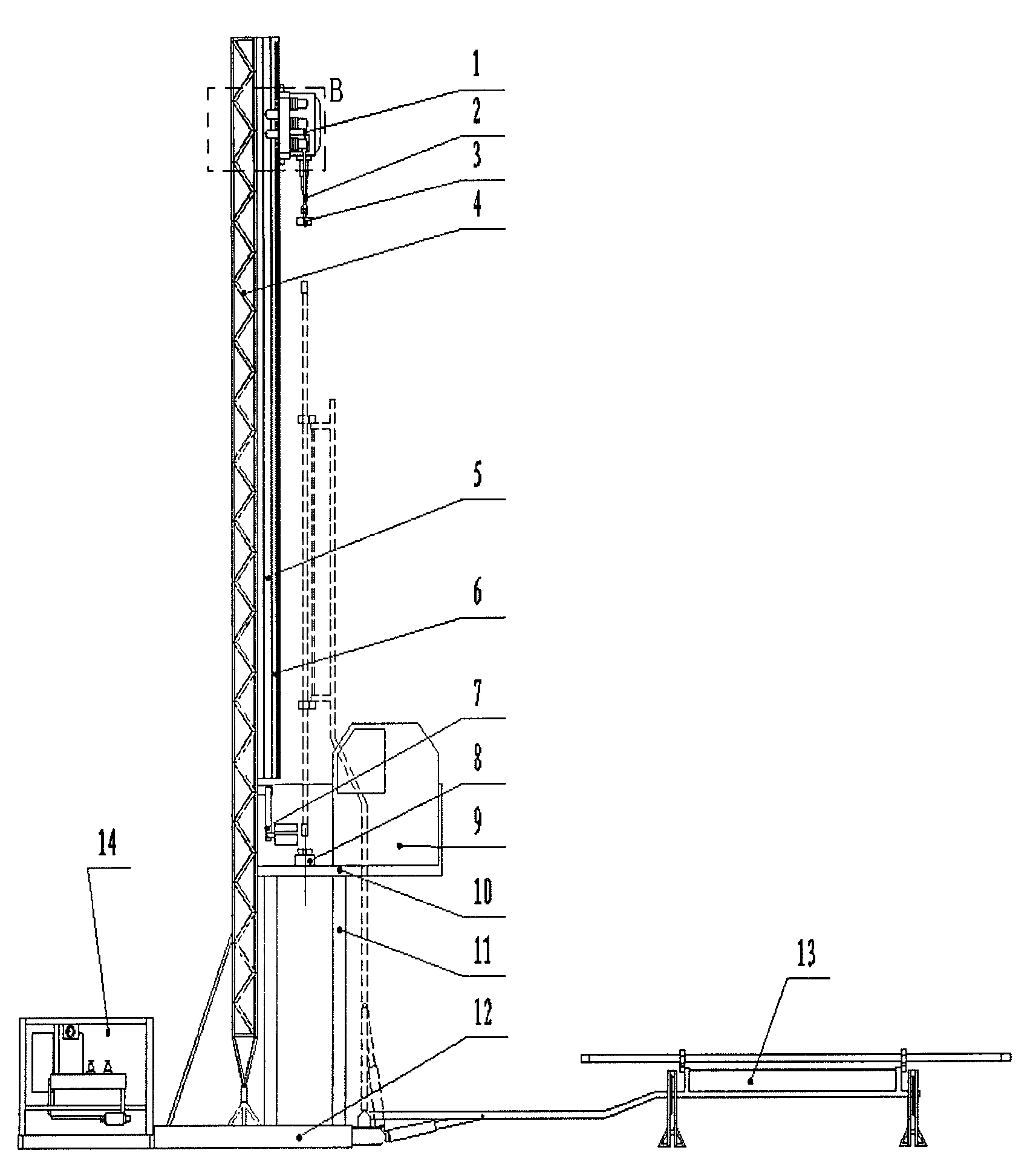

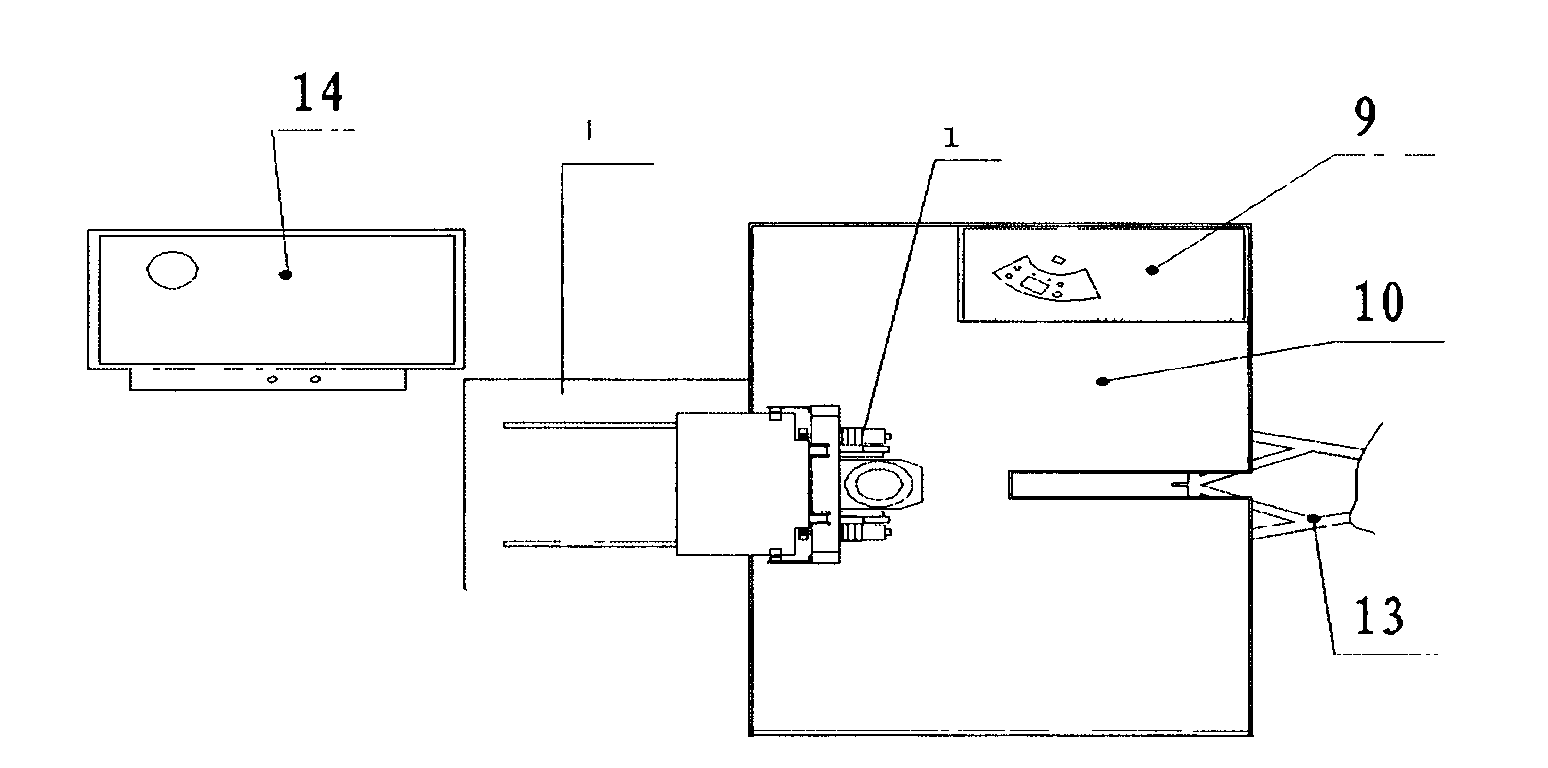

[0025] see figure 1 and figure 2 , the bottom of the derrick 4 is vertically fixed on the base 12, and the two racks 6 and guide rails are respectively symmetrically fixed on both sides of the derrick 4 in parallel. Guide rail 5 reciprocates up and down. Support beam 11 is fixed on the base 12, and operating platform 10 is installed on its upper end. The operation control room 9 is placed on the side of the drilling floor 10 away from the derrick. The hydraulic make-up and breakout mechanism 7 and the hydraulic chuck 8 are placed on the drill floor near the wellhead. One side of the base 12 is provided with a hydraulic drive mechanism 14, and the other side is provided with a drill pipe transfer device 13.

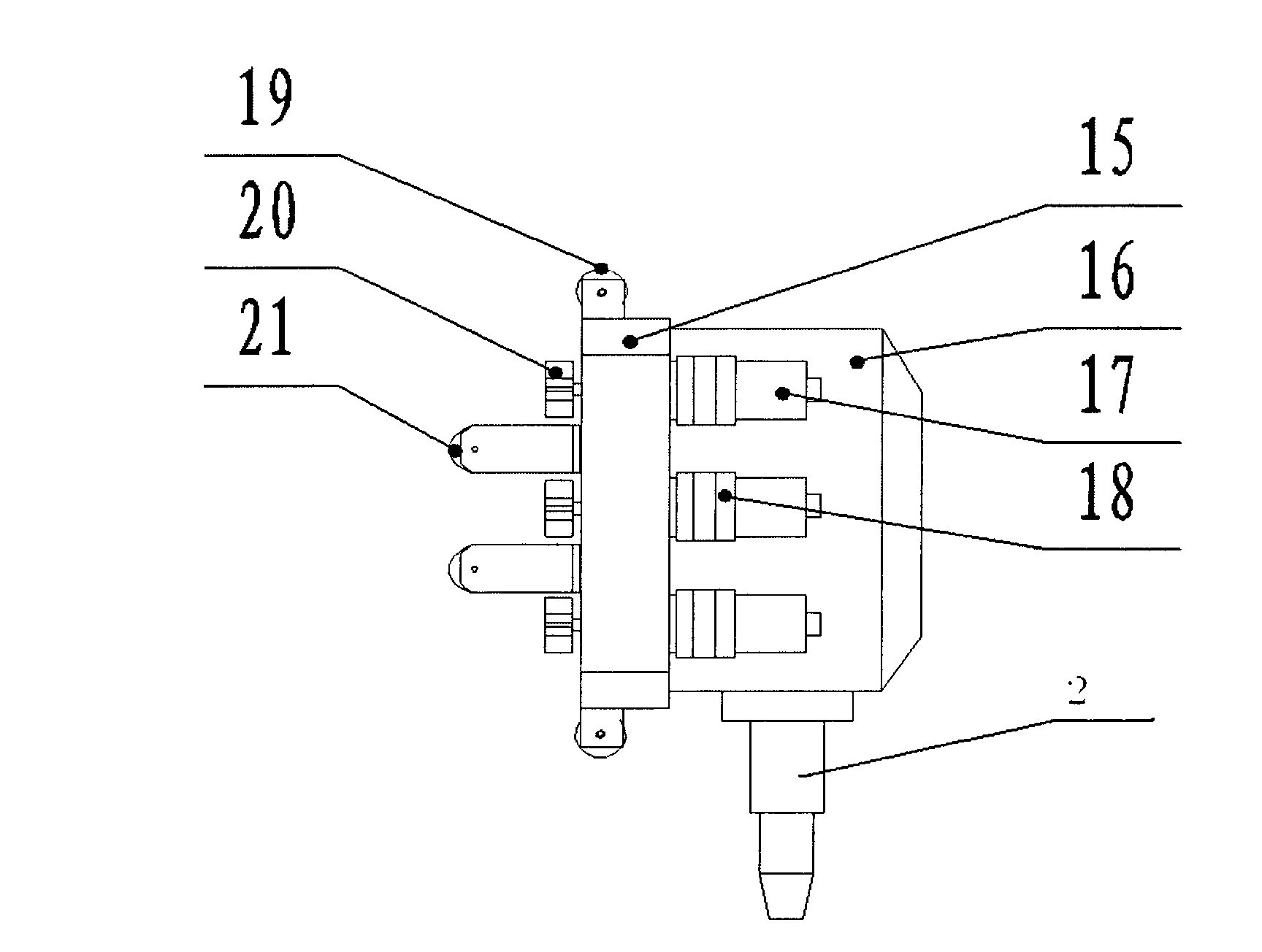

[0026] see image 3 , Figure 6 and Figure 7 , The lifting device 1 includes a main body panel 15, a top drive head 16, a small motor 17, a brake mechanism 18, a front roller 19, a gear 20, a rear roller 21, a suspension ring 2, and an elevator 3. The brake mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com