Elevator lift car load weighing device

A technology of elevator car and weighing device, which is applied in the direction of transportation and packaging, elevators, etc., and can solve problems such as difficult rubber deformation, inconvenient operation, and inaccurate car load measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

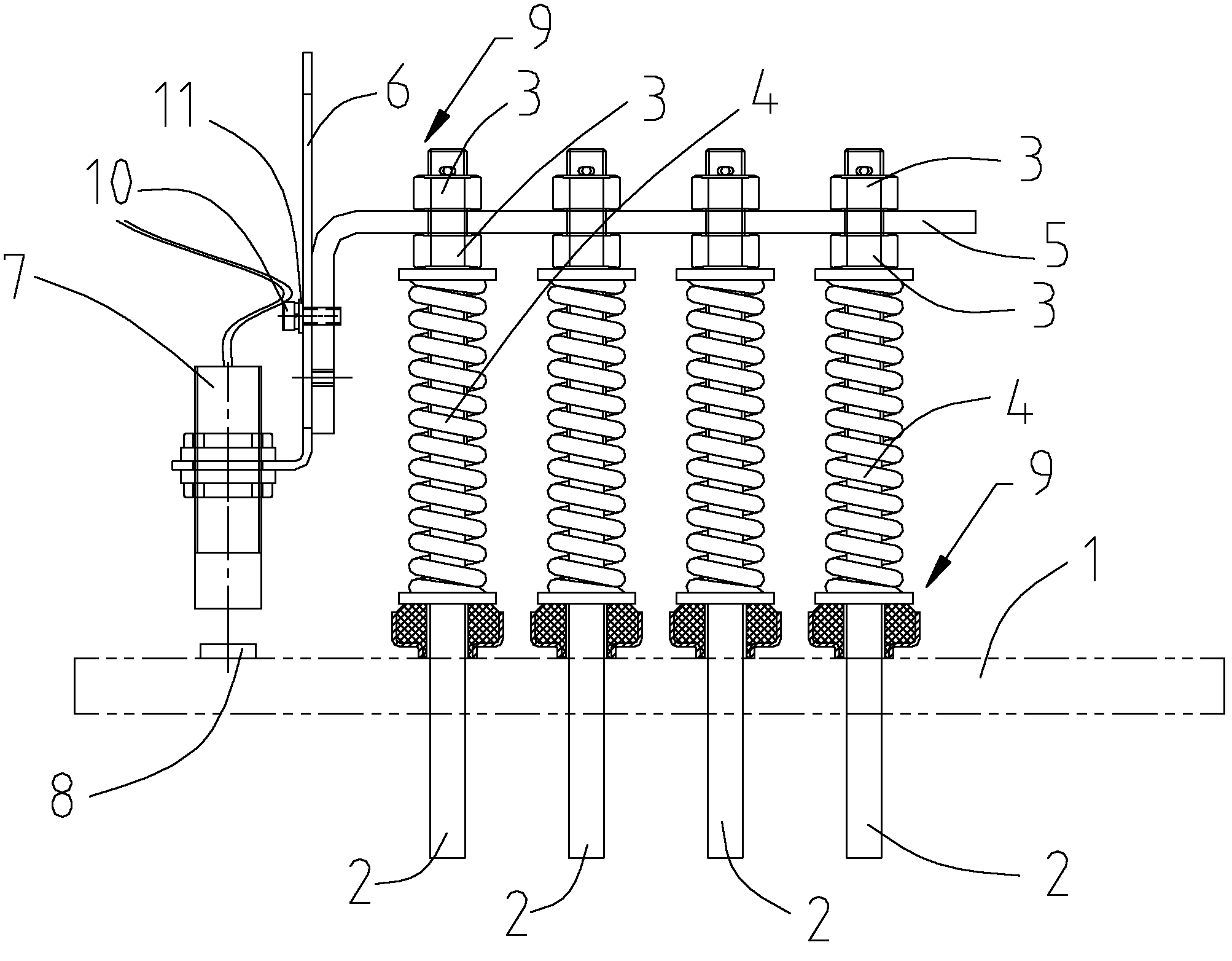

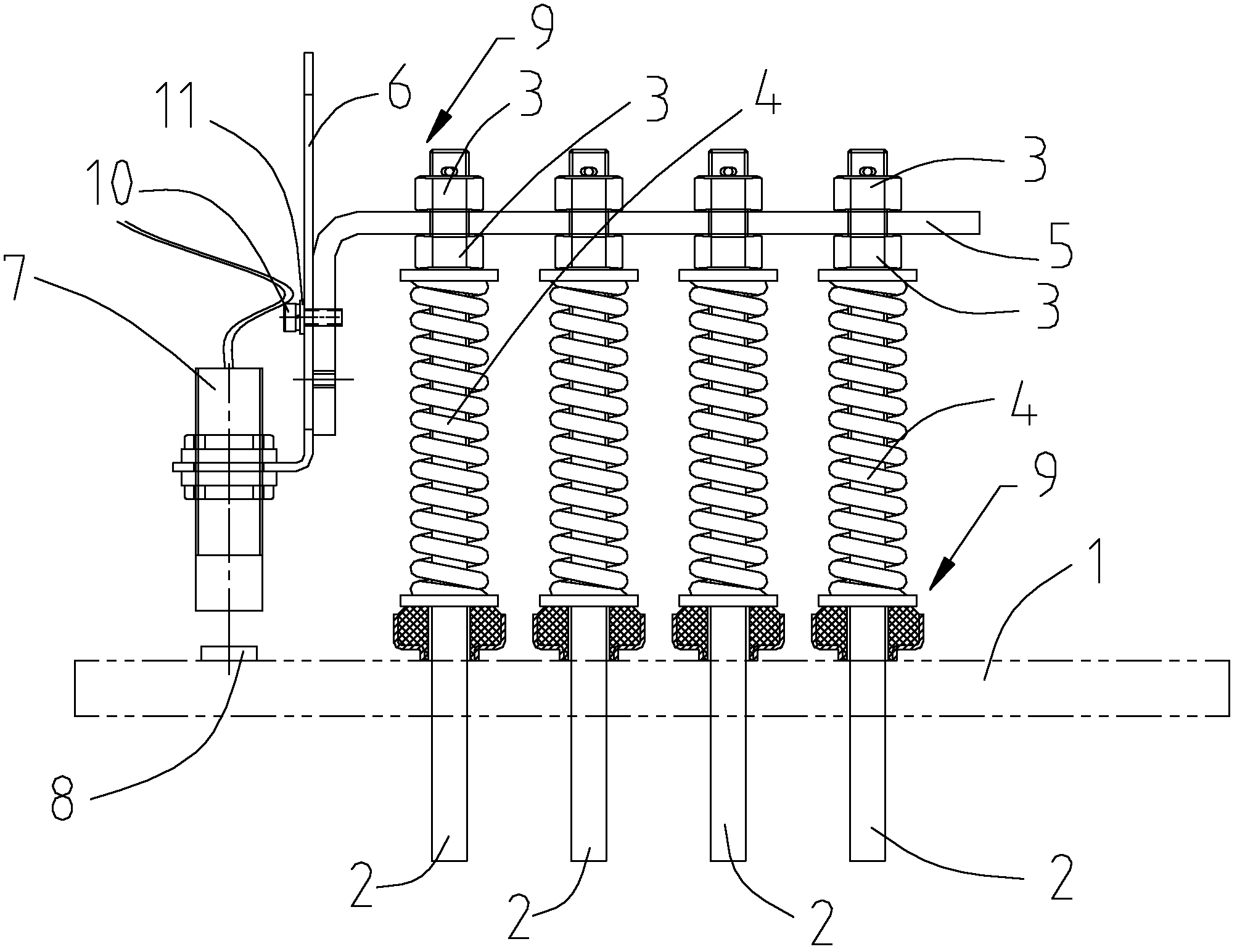

[0010] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] see figure 1 As shown, the elevator car load weighing device includes a rope head plate 1, a rope head assembly 9 arranged on the rope head plate 1, a mounting plate 5, a sensor probe 7 mounted on the mounting plate 5, and a rope head plate mounted on the rope head plate. The sensor square magnetic steel 8 on 1, the rope head plate 1 is provided with installation perforation, the rope head assembly 9 includes a screw rod 2 that can slide through the installation perforation, a pair of nuts 3 that are threaded on the screw rod 2, set Between the screw rod 2 and the rope head plate 1 is used to provide the elastic member 4 of the elastic recovery force of the screw rod 2, figure 1 The screw rod 2 is arranged vertically, the lower end of the screw rod 2 can slide through the installation hole of the rope head plate 1 along its axial directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com