Rail vehicles and their brake components

A technology for brake components and brake discs, which is applied to brake components, operating mechanisms of railway vehicle brakes, vehicle components, etc., can solve problems such as the inability to meet the requirements of changing gauge operation, and achieve the ability to adapt to changing gauge conditions. Improve and improve the effect of horizontal position adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The core of the present invention is to provide a brake assembly, which has a wide range of lateral movement capability, and can fully meet the requirements of the operating conditions of rail vehicles when the gauge is changed; at the same time, it provides a track using the brake assembly. vehicle.

[0023]In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

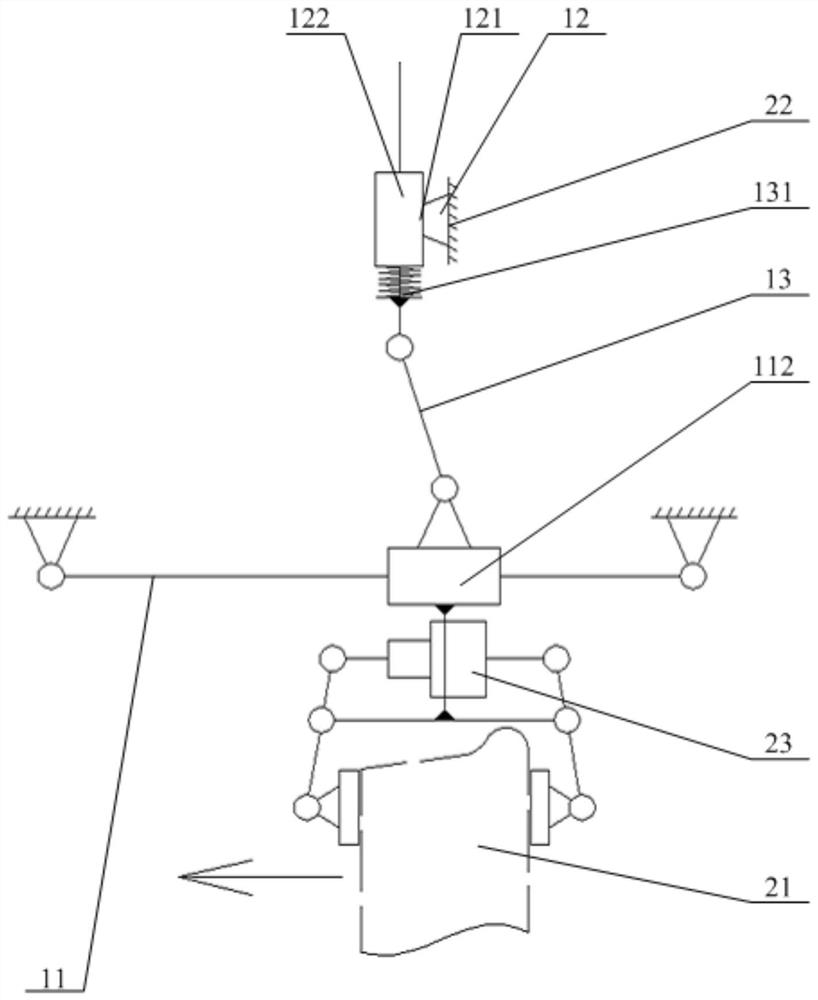

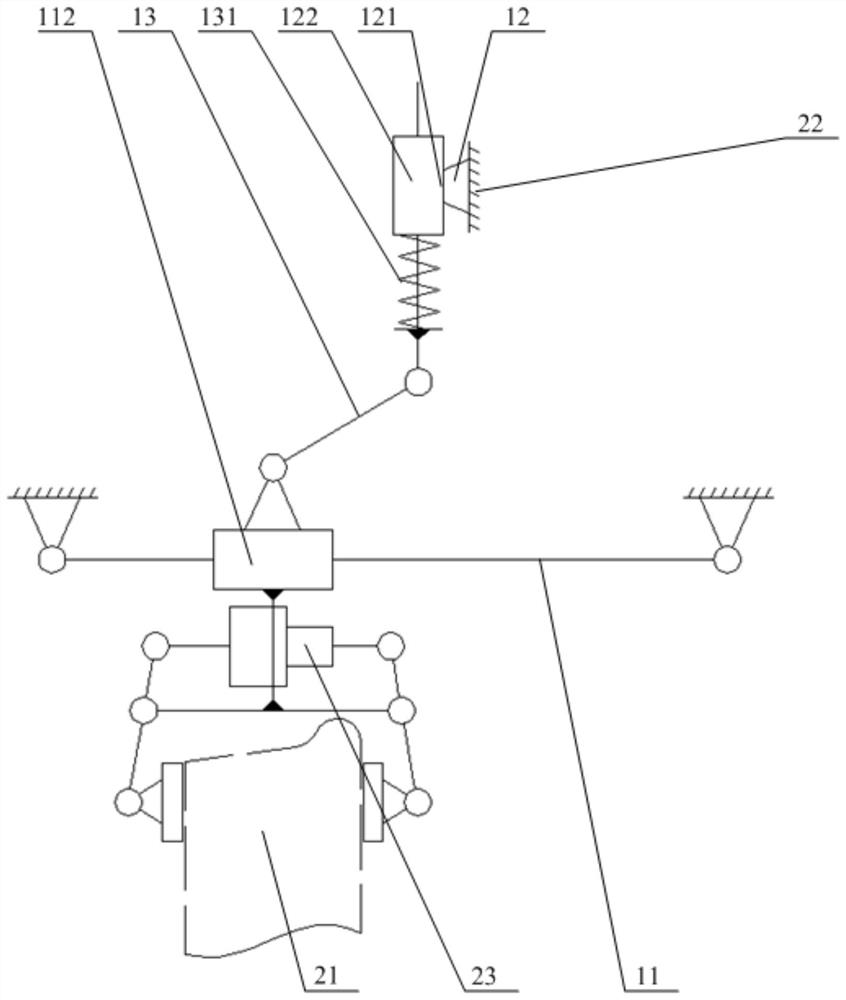

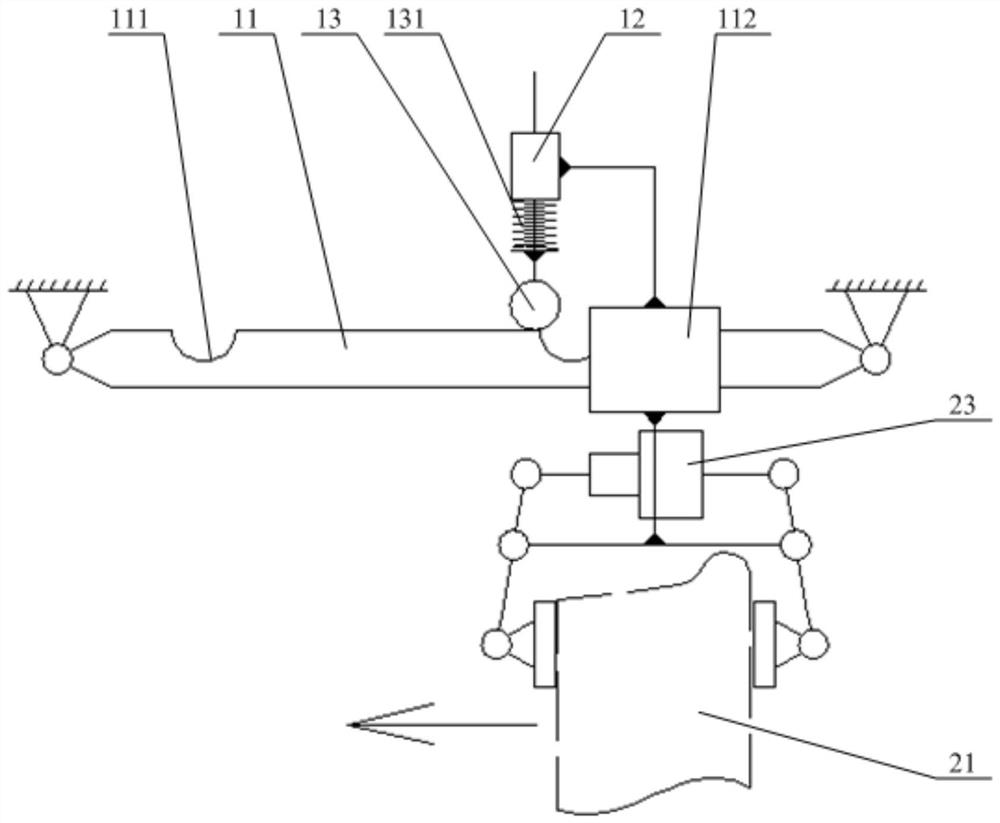

[0024]Please refer tofigure 1 withfigure 2 ,figure 1 It is a schematic diagram of the structure of the brake assembly during the movement provided by a specific embodiment of the present invention;figure 2 forfigure 1 Schematic diagram of the structure after the middle brake assembly has completed its action.

[0025]In a specific embodiment, the brake assembly provided by the present invention includes a brake disc 21 disposed under the frame 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com