Development method of blind shaft frame for surface and underground parallel construction

A pioneering method and parallel construction technology, applied in the field of well construction and underground mining, can solve the problems affecting the mine production time, long construction period and poor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

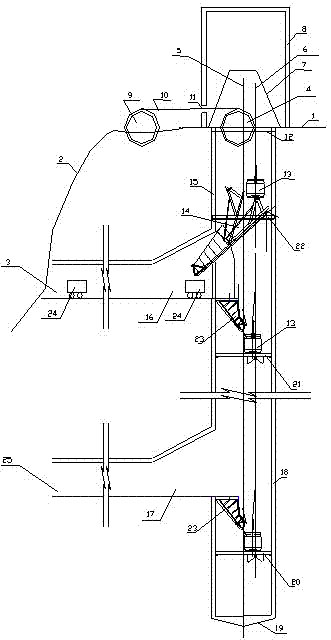

[0039] 1. The construction of the main shaft system of Baixiangshan Iron Mine of Gushan Mining Company of Masteel Group uses construction machines including: hoist, sinking derrick, sinking stabilizer, sky wheel platform, bucket, grabbing machine, mine car, ground sliding form Hydraulic system.

[0040] 2. The construction of the main shaft system of Baixiangshan Iron Mine of Gushan Mining Company of Masteel Group adopts the underground derrick development method of parallel construction above and below the mine, and proceeds according to the following steps:

[0041] 1) Set the sinking derrick on the ground

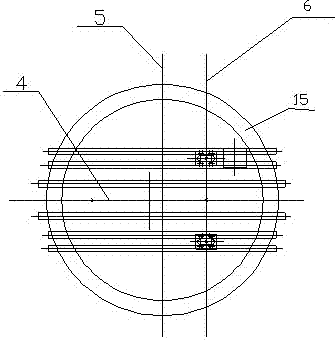

[0042] a. According to the design coordinates, use the nearby plane and elevation control points to set the wellbore centerline 5 on the ground 1, set the wellbore cross line as the basis for the wellbore construction plane and elevation control, and set the lifting centerline 6 as the basis for the layout of the lifting facilities;

[0043] b. Set up the sinking derric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com