Lining grinding mechanism for pipe die repairing

A tube die and grinding technology, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding workpiece supports, etc. Low noise, reduce motor power, overcome the effect of easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

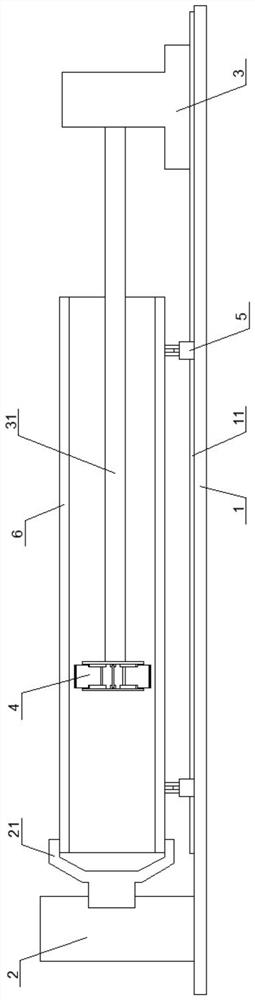

[0023] Such as figure 1 As shown, an inner wall grinding mechanism of a pipe mold includes a base 1 , a head frame 2 , a trolley 3 , a grinding mechanism 4 , an axial drive device and at least one bracket 5 . Both the head frame 2 and the bracket 5 are installed on the top of the base 1 .

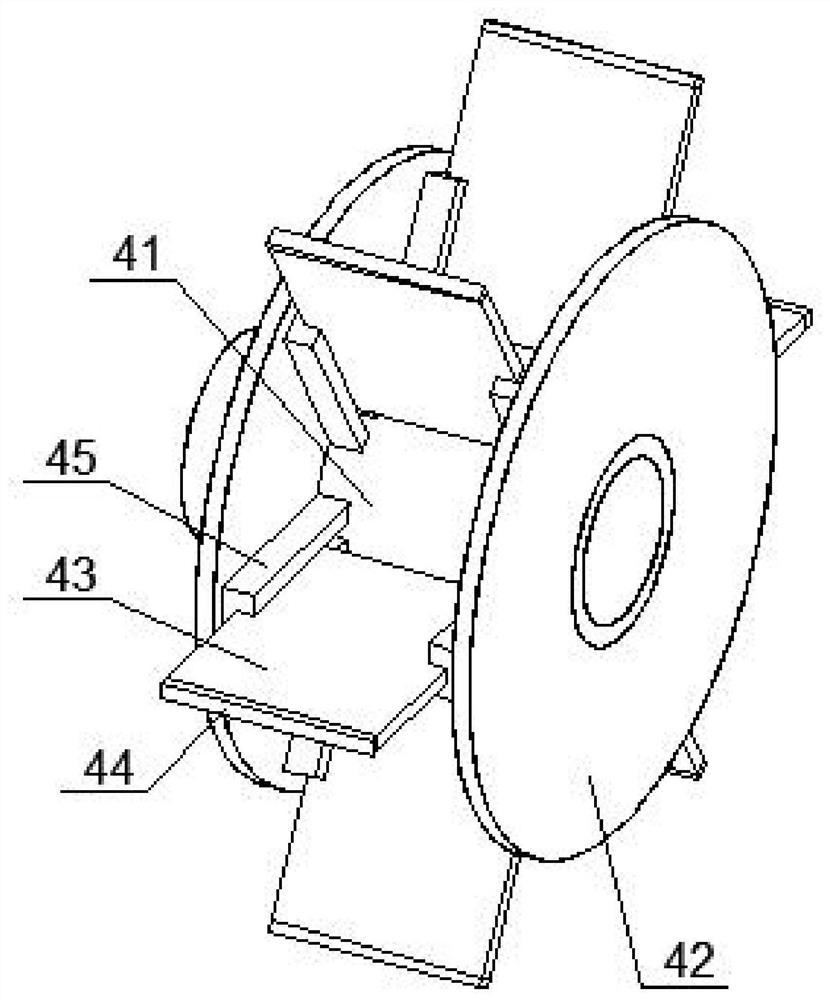

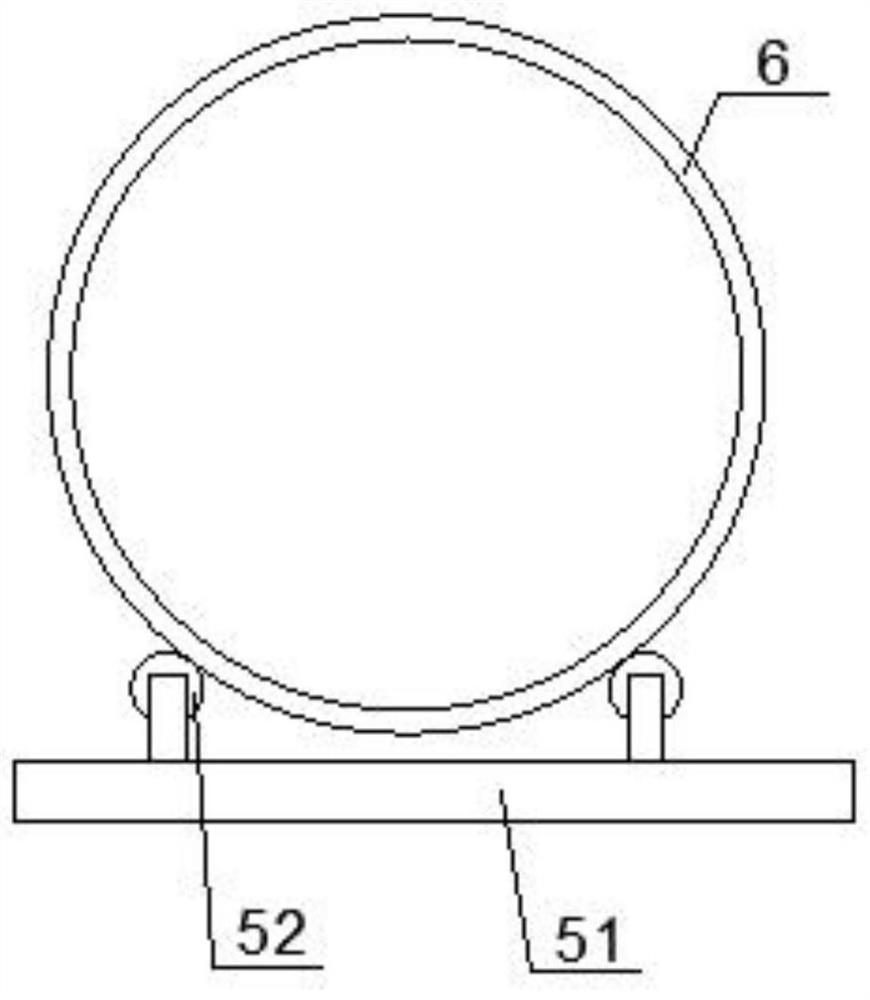

[0024] The head frame 2 is equipped with a chuck 21 near the side of the bracket 5, and the chuck 21 is fixedly connected to one end of the pipe mold 6 coaxially, and a rotary drive mechanism (not shown) is also installed on the head frame 2 The rotary drive mechanism is connected to one end of the chuck 21 and drives the chuck 21 to rotate, thereby driving the pipe mold 6 to rotate. Such as image 3 As shown, the bracket 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com