Method and system for morphology deviation correction of optical glass products

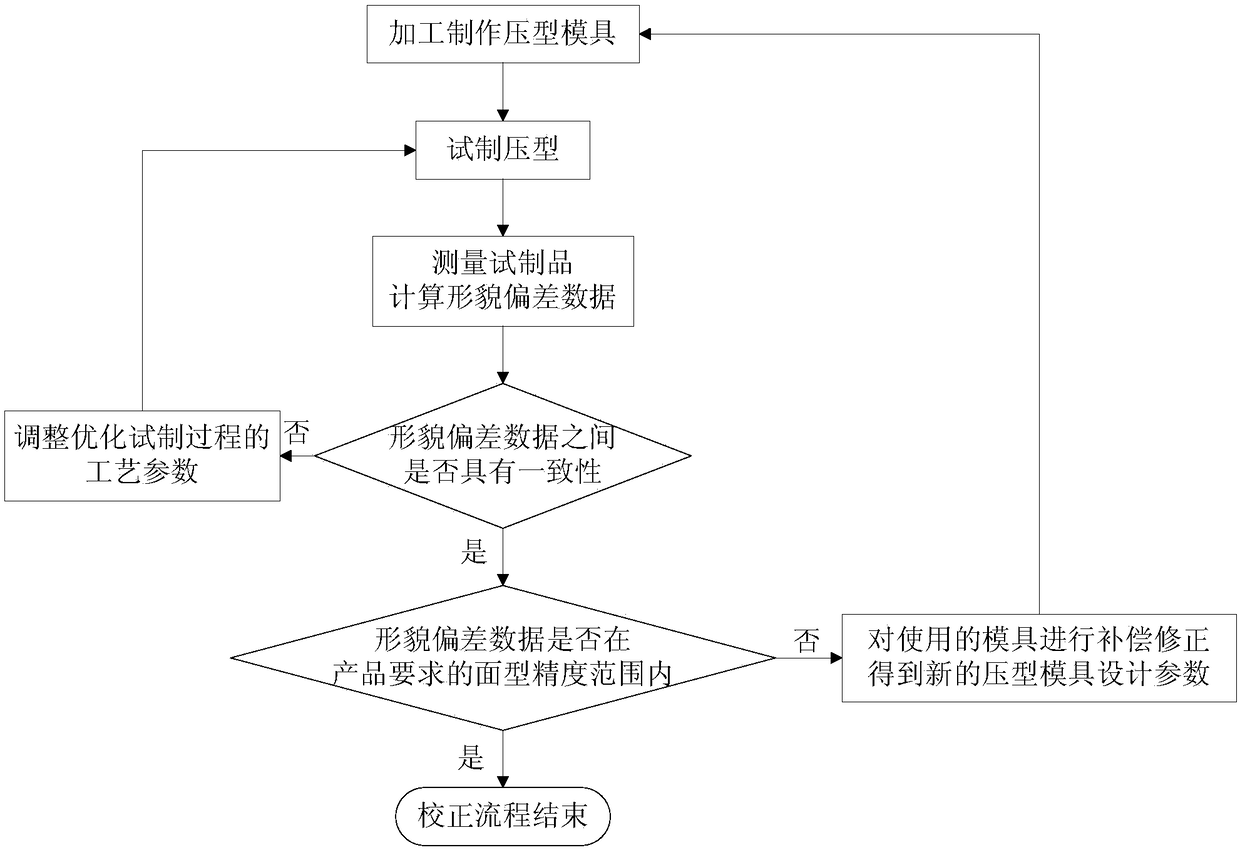

A technology of optical glass and correction method, which is applied in the direction of glass pressing, glass manufacturing equipment, glass molding, etc., can solve the problems of long correction period of shape deviation of pressed products, large correction error, etc., to reduce unstable factors, Reduce the workload and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

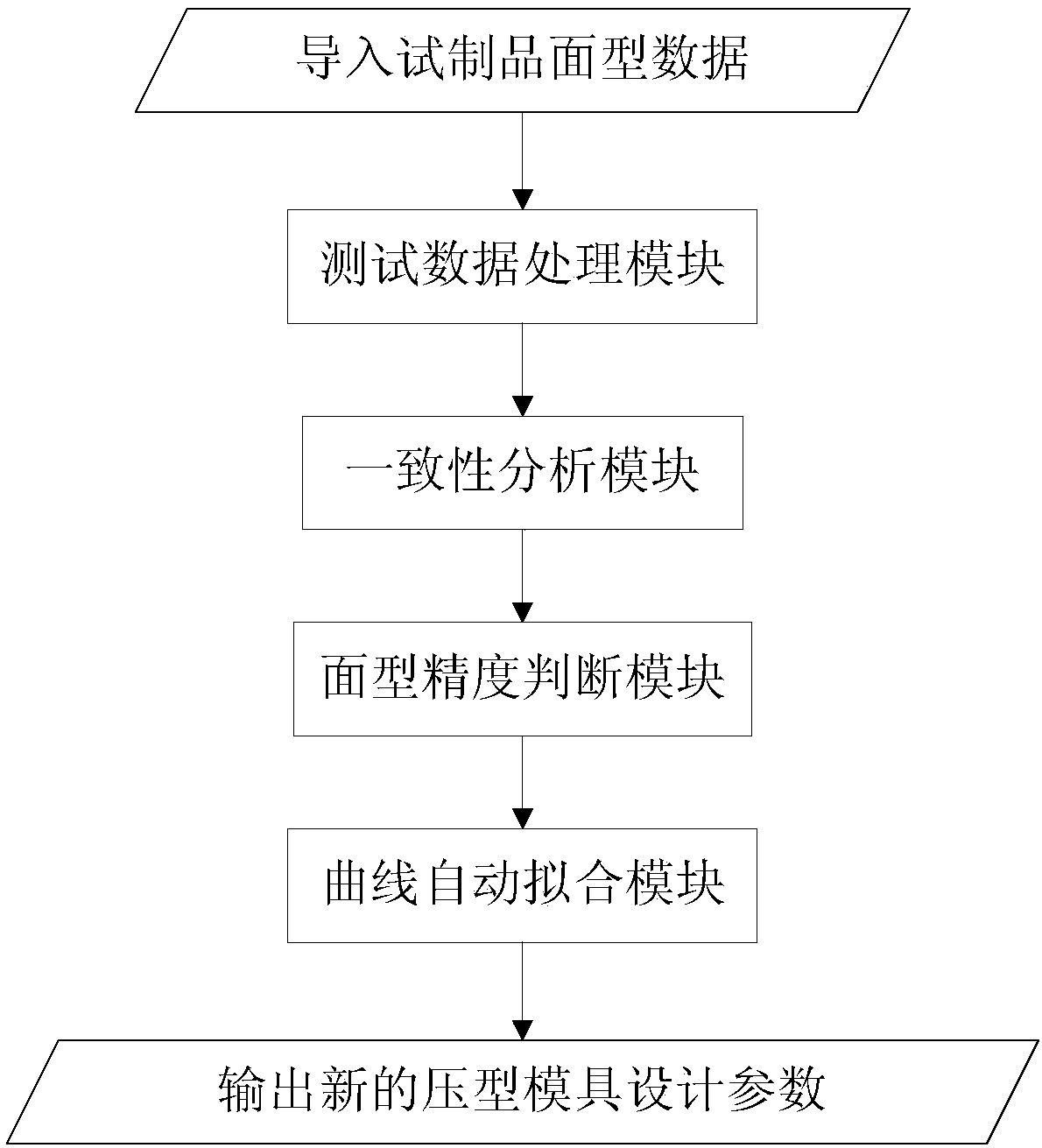

Method used

Image

Examples

Embodiment 1

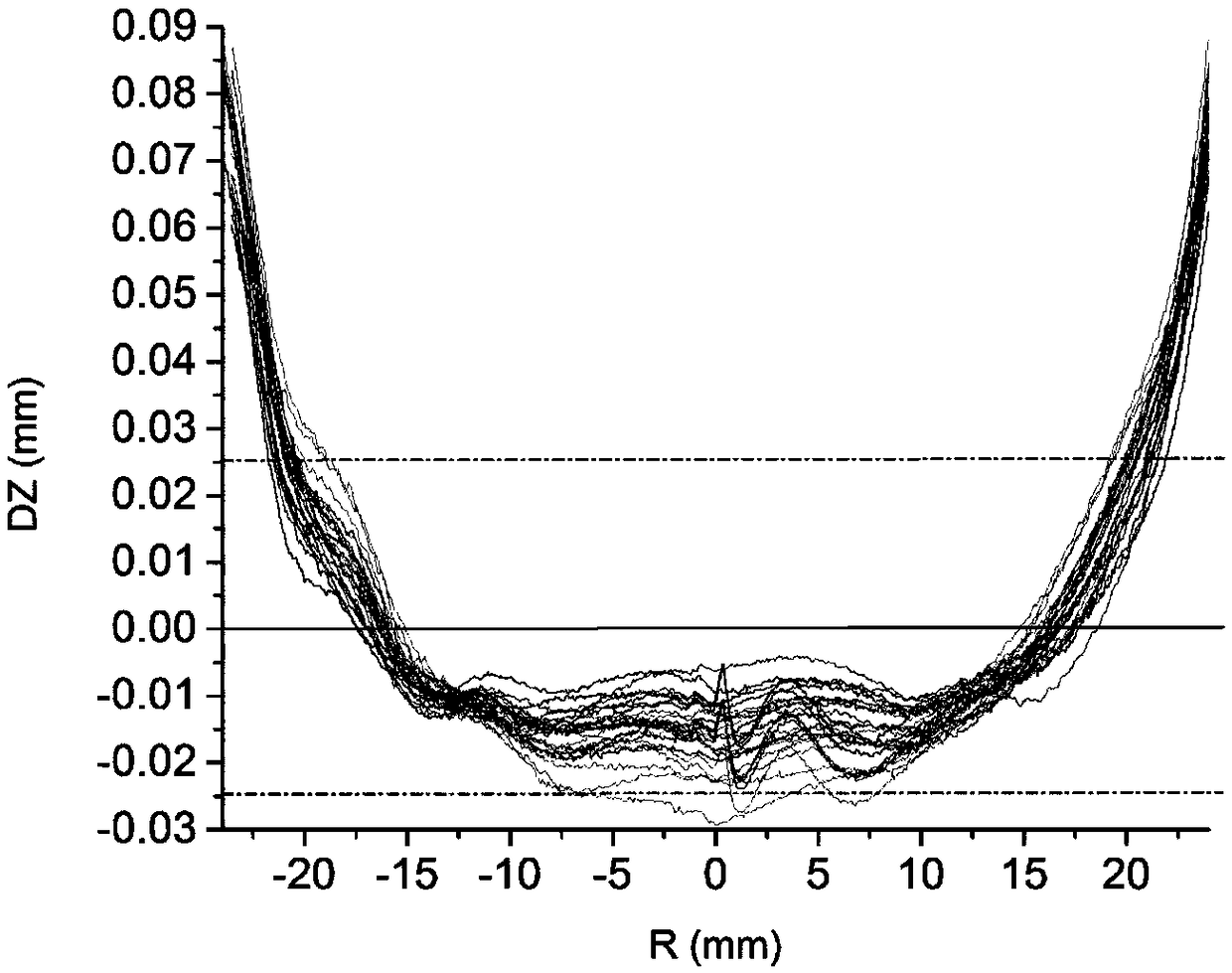

[0082] Taking an aspheric lens product with a maximum cross-sectional diameter of 48mm as an example, its surface equation is shown in formula (1), and the values of the parameters in the formula are shown in Table 1. The customer's surface accuracy requirement for the product is ±25μm, as shown in Table 1. According to the parameters in 1, the mold cavity is preliminarily designed, processed and trial-manufactured, and 6 samples are randomly selected from the obtained trial products for three-coordinate testing, and 4 sets of surface data are tested for each sample, and the optical glass product morphology provided by the present invention is adopted The deviation correction system conducts a consistency analysis on the deviation data of the surface shape of the sample and the standard value, and obtains image 3 result.

[0083] Table 1 The standard formula parameter table of the aspheric lens product with a diameter of 48mm

[0084] formula parameters

C

K...

Embodiment 2

[0094] For an aspheric lens product with a maximum cross-sectional diameter of 60mm, its surface equation is shown in formula (1). The cavity of the molding die is preliminarily designed based on the parameters in the drawing, and then processed and trial-manufactured. Four of the obtained trial products are randomly selected. Three-coordinate testing is carried out on the sample, and 4 sets of surface data are tested for each sample, and the optical glass product shape deviation correction system provided by the present invention is used to analyze the consistency of the shape deviation data between the sample surface and the standard value, and the obtained Figure 6 result. from Figure 6 It can be seen from the figure that the consistency of the 16 shape deviation curves is poor, indicating that the production process parameters in the pressing process are unstable, and the conditions for correction of the shape deviation are not available. It is necessary to continue to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com