Printing method of product profile in FDM (Fused Deposition Modeling) printing

A technology for printing products and products, which is applied in the field of 3D printing. It can solve the problems of many times of printing head operation, layer surface strain, and low printing efficiency, and achieve the goal of reducing printing idling travel, avoiding scratches, and avoiding printing process costs. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

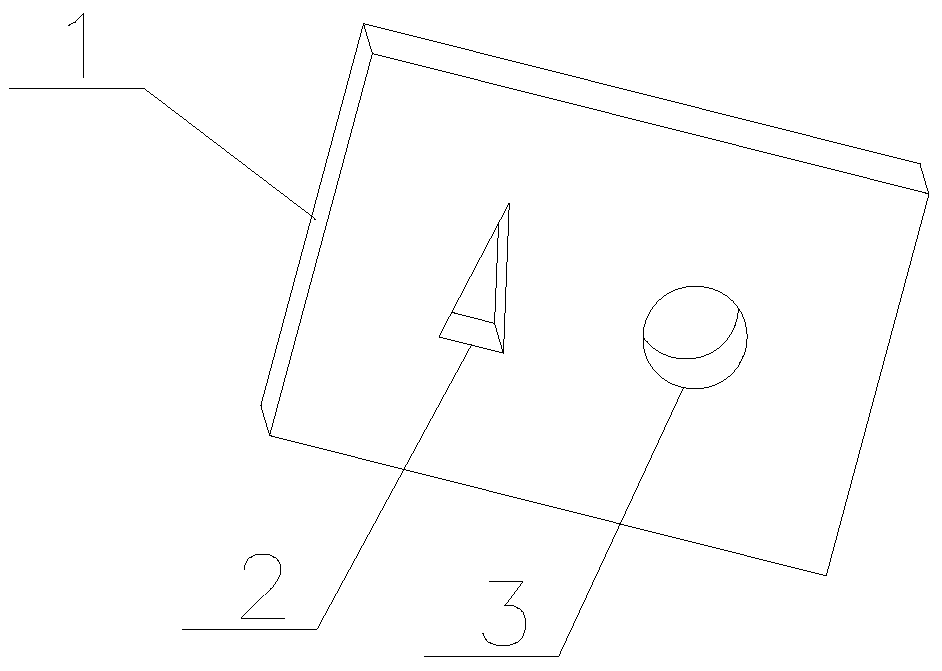

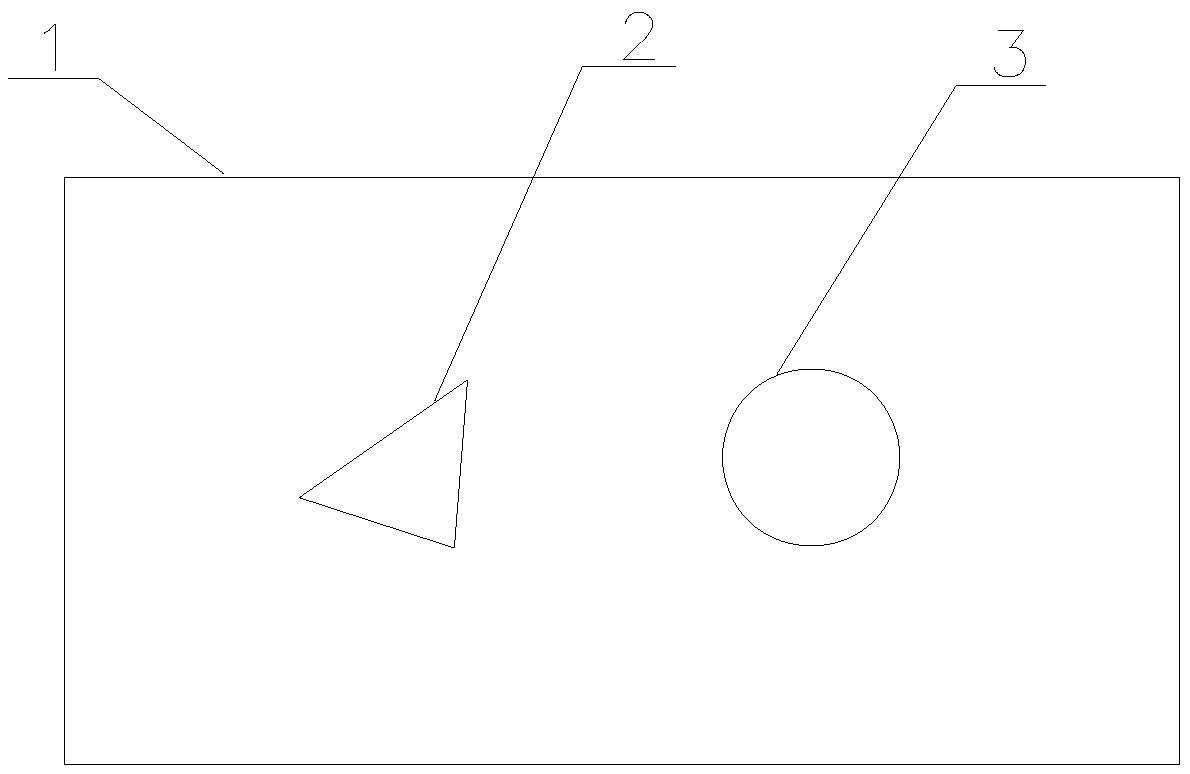

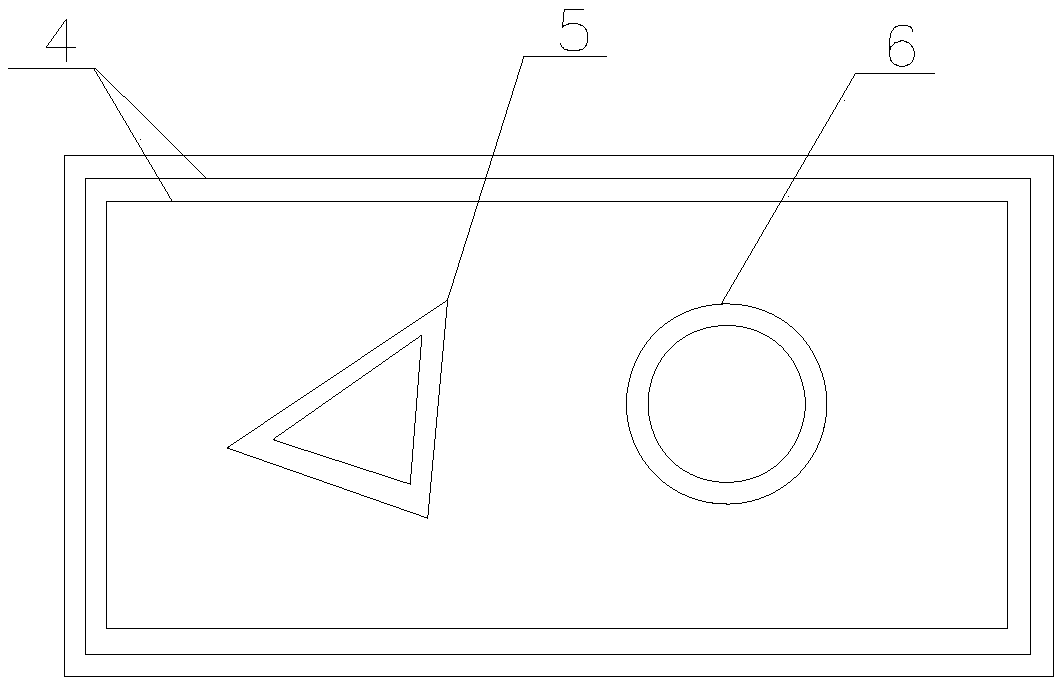

[0025] Below to image 3 The three-dimensional mold shown is taken as an example, and the printing method of the product outline in the FDM printing of the present invention is described in detail. according to figure 1 The printing process shown in the figure prints the three-dimensional model shown in the figure. The outer contour 1 of the three-dimensional model is a cuboid, and the inner contour is a triangular hollow structure and a circular hollow structure respectively. The specific printing method includes the following process:

[0026] In the first step, the three-dimensional slicing software will image 3 The three-dimensional model of the product shown is sliced into 20 layers, read the three-dimensional data information of each sliced surface, and convert the three-dimensional data information into two-dimensional graphic data information;

[0027] In the second step, according to the thickness requirements of the surface layer of the printed product and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com