Production method of circular-blow multi-end bright profiled polyester filament yarns more than 3dpf (denier per filament)

A special-shaped polyester filament and production method technology, applied to the melting of filament raw materials, filament/thread forming, single-component polyester artificial filament, etc., can solve the problems of immature ring blowing technology and achieve product quality Good drying uniformity, advantages of production stability, obvious effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

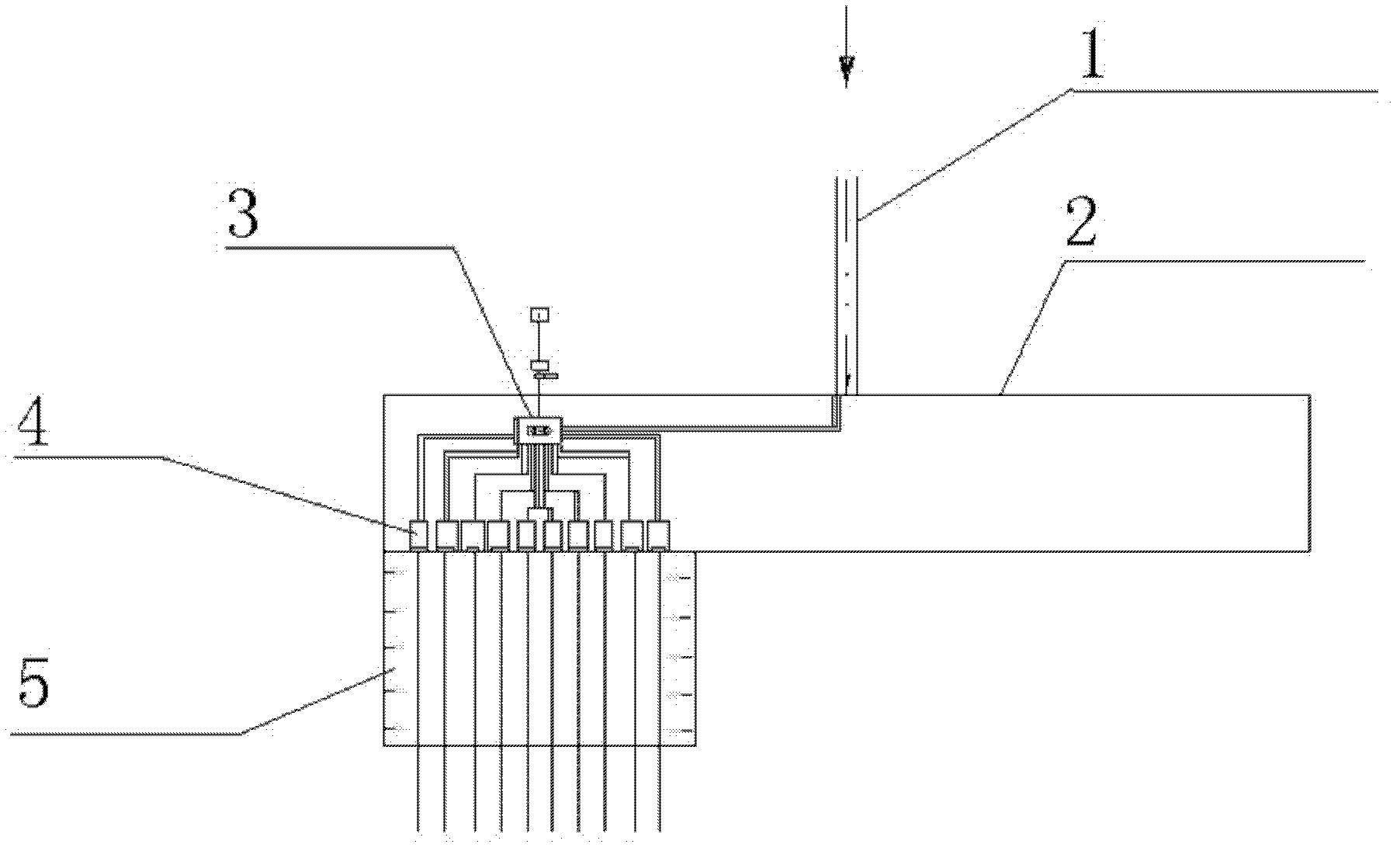

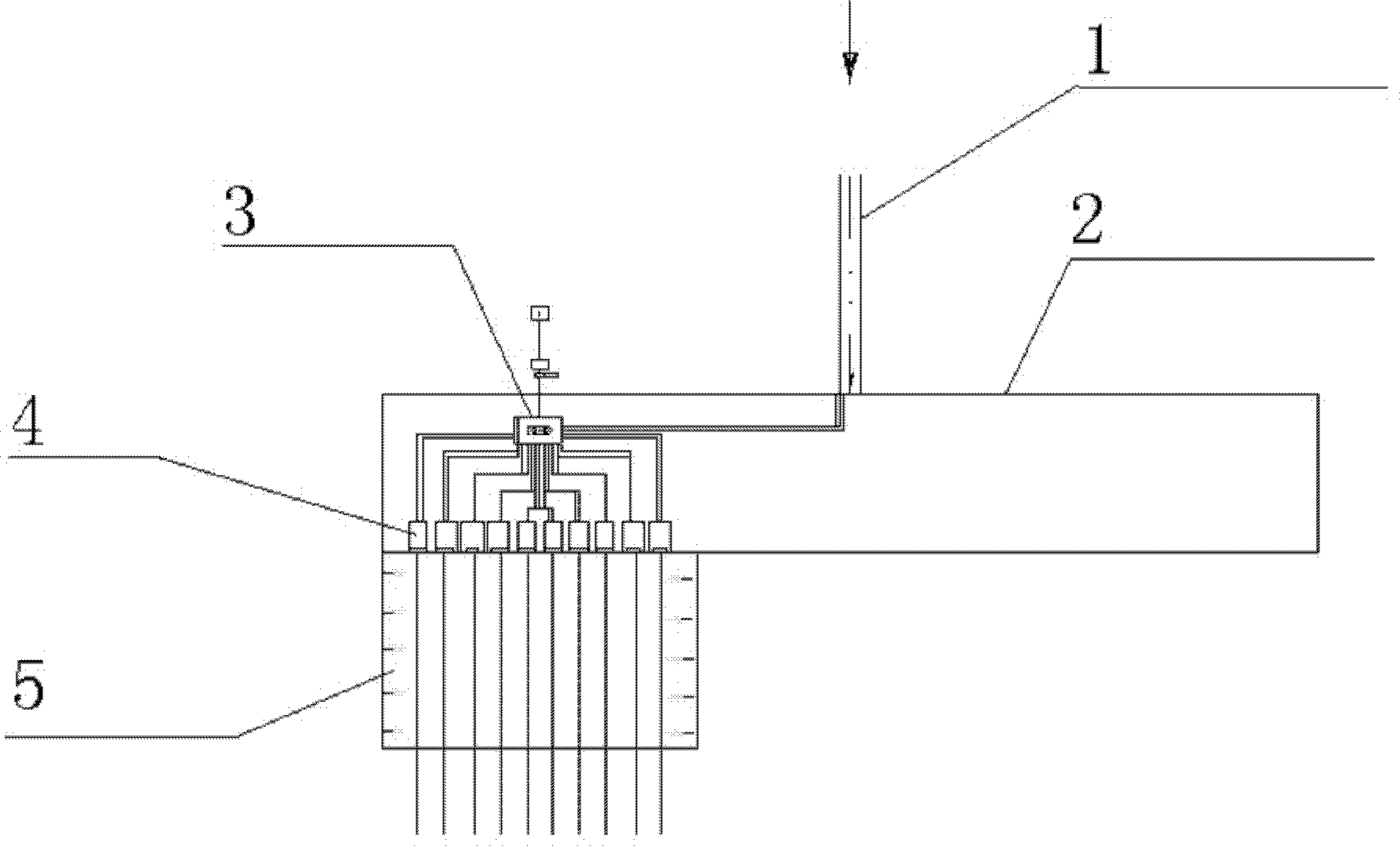

[0015] The production method of ring-blown multi-end bright special-shaped polyester filaments above 3dpf described in this embodiment uses bright polyester melt as raw material, and the bright polyester melt is increased by a booster pump through a melt delivery pipeline 1 After pressing, it enters the melt cooler. After the melt is cooled by the melt cooler, it is sent to the spinning box 2, after being metered by the metering pump 3, and then filtered by the spinning assembly 4 in the spinning box 2 and extruded After being cooled and solidified by the spinning ring blowing device, the nascent fiber is oiled by the oil nozzle and pre-networked by the network device. After the godet roller integrated on the winder controls the tension required by the process, the tow is introduced into the winder. Assembling and forming, in which: the temperature of the melt conveying pipeline 1 is 277℃ for melt conveying;

[0016] The spinning box 2 is spun at 288°C, and the spinning assembly ...

Embodiment 2

[0020] The production method of ring-blown multi-end light profiled polyester filaments above 3dpf described in this embodiment includes:

[0021] 1) After filtering the bright polyester melt processed by the polymerization melt cooler, it is pressurized by the booster pump through the melt conveying pipeline 1, and the viscosity drop is ≤0.012 after being processed by the spinning melt cooler again The uniform and stable high-quality polyester melt enters the spinning box 2, after being accurately metered by the metering pump 3, enters the independent cavities of the spinning assembly 4 in the spinning box 2, and is extruded after filtering. The temperature of the polyester melt treated with the secondary cooler is 278°C, the temperature of the spinning box 2 is 294°C, and the spinning speed is 3150m / min.

[0022] 2) The tow is cooled and solidified into a nascent fiber by a spinning ring blowing device with a ring blowing tube length of 260mm, where the length of the airless zone...

Embodiment 3

[0025] The production method of ring-blown multi-end bright shaped polyester filaments above 3dpf described in this embodiment includes:

[0026] 1) After filtering the bright polyester melt processed by the polymerization melt cooler, it is pressurized by the booster pump through the melt conveying pipeline 1, and the viscosity drop is less than 0.012 after being processed by the spinning melt cooler again. The uniform and stable high-quality polyester melt enters the spinning box 2 after being accurately metered by the metering pump 3, enters the independent cavities of the spinning assembly 4 in the spinning box 2, and is extruded after filtering. The temperature of the polyester melt treated by the secondary cooler is 282°C, the temperature of the spinning box 2 is 289°C, and the spinning speed is 3000m / min.

[0027] 2) The tow is cooled and solidified into a nascent fiber by a spinning ring blowing device with a wind tube length of 230mm, where the length of the windless zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com