Food processing method

A production method and food technology, applied in food science, meat clamping device, metal processing, etc., can solve the problems of affecting cutting, cutting irregularly, leaving a lot of bone debris, etc., to save time, beautiful and neat appearance, The effect of saving space and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

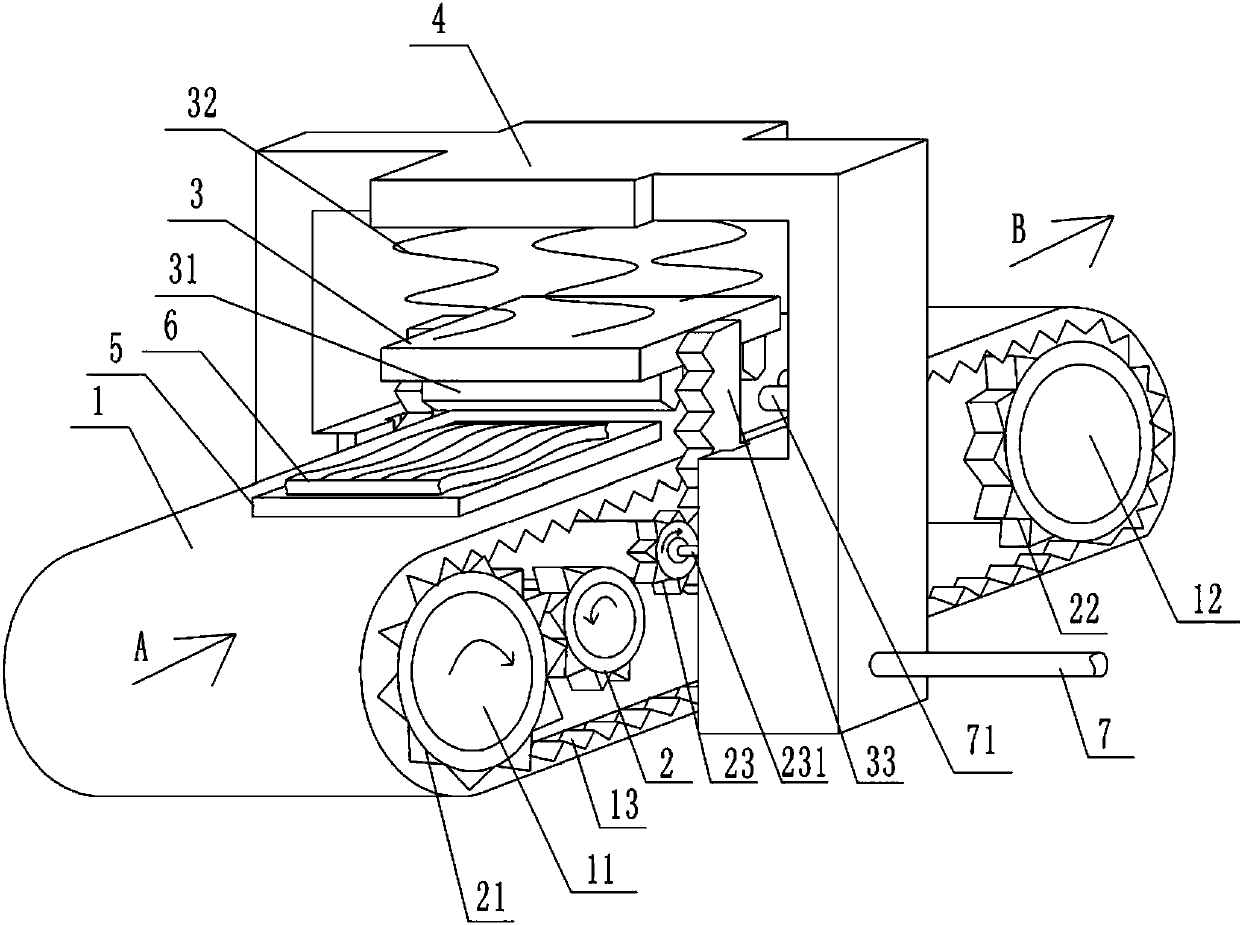

[0023] Instructions attached figure 1 The reference signs in include: transmission surface 1, main transmission shaft 11, auxiliary transmission shaft 12, meshing teeth 13, conveyor belt input end A, conveyor belt output end B, driving gear 2, first transmission gear 21, second transmission Gear 22, power gear 23, rotating shaft 231, upper plate 3, cutter 31, spring 32, rack 33, support mechanism 4, place plate 5, chop 6, water inlet pipe 7, shower nozzle 71.

[0024] Such as figure 1 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0025] A food production method, using a food production device for production: the food production device includes a transmission mechanism, a cutting mechanism, a support mechanism 4, a washing mechanism, and a placement plate 5 for placing ribs 6, and the bottom surface of the placement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com