Multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method

A technology of countercurrent washing and acid leaching, which is applied to chemical instruments and methods, separation methods, filtration and separation, etc. It can solve problems such as multiple washing effects of equipment, poor process water, and complicated processes, so as to realize the concept of clean production and reduce environmental pollution. Risk, Effect of Simplified Steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

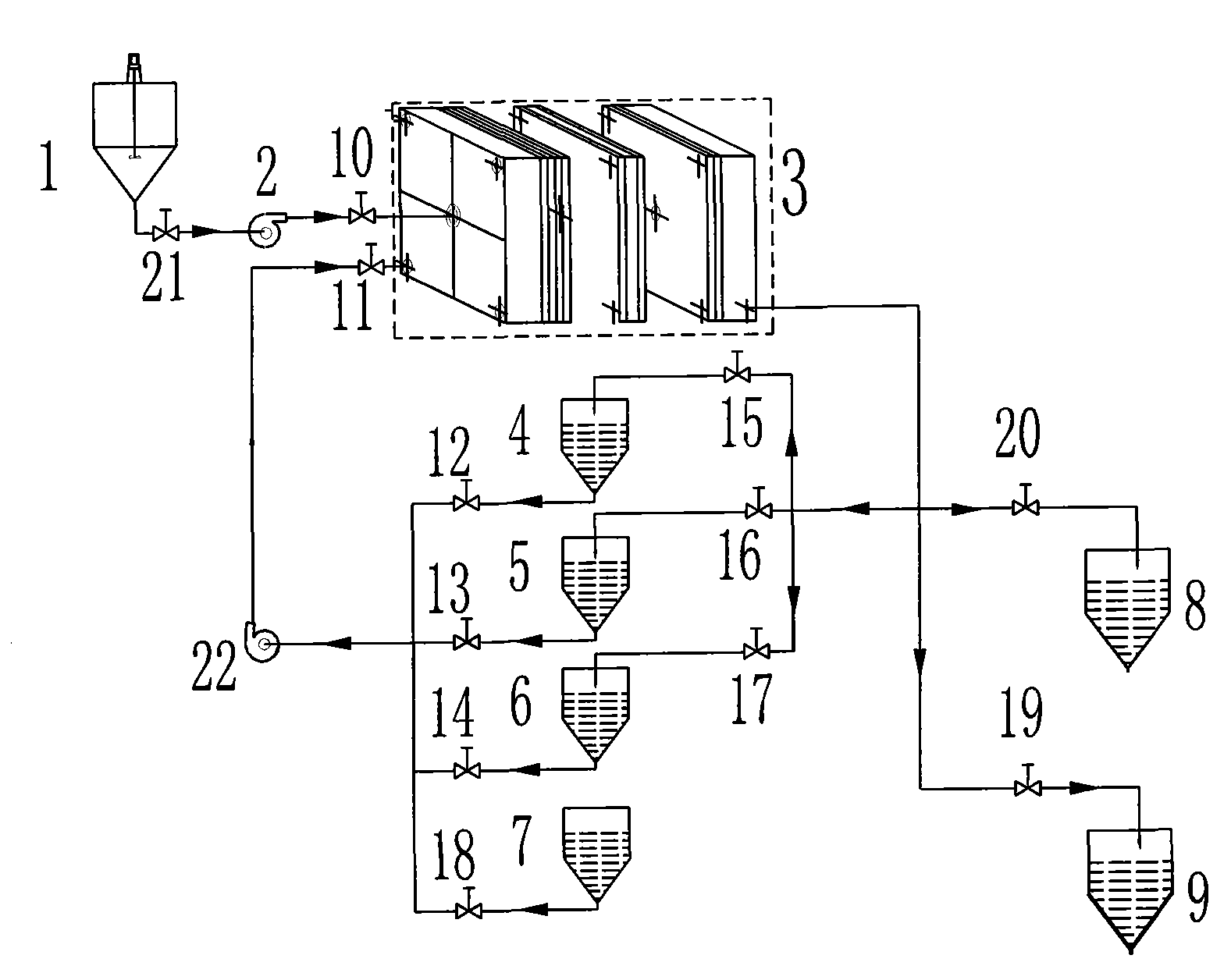

[0051] As a specific embodiment of the present invention, the integrated system of the present invention is used to carry out integrated treatment of multi-stage acid leaching, multi-stage countercurrent washing, and pressure filtration on zinc calcine. The zinc calcine used in this embodiment is dissolved in water The zinc content is 127g / l (as Zn 2+ ), the content of undissolved zinc in the residual zinc slag filter cake after acid leaching is 16%, and the content of water-soluble zinc is 5% (calculated as Zn). Such as figure 1 As shown, the specific implementation steps are as follows:

[0052] 1) Open the control valves 10, 20, 21 and the pump 2, inject the zinc calcine in the feeding tank 1 into the membrane filter press 3 directly, and the filter press fluid flows into the filtrate pool 8, when the filter residue fills the entire membrane filter press When the filter plate chamber of the machine 3 is closed, the pump 2 and the control valves 10, 20, 21 are closed;

[...

Embodiment 2

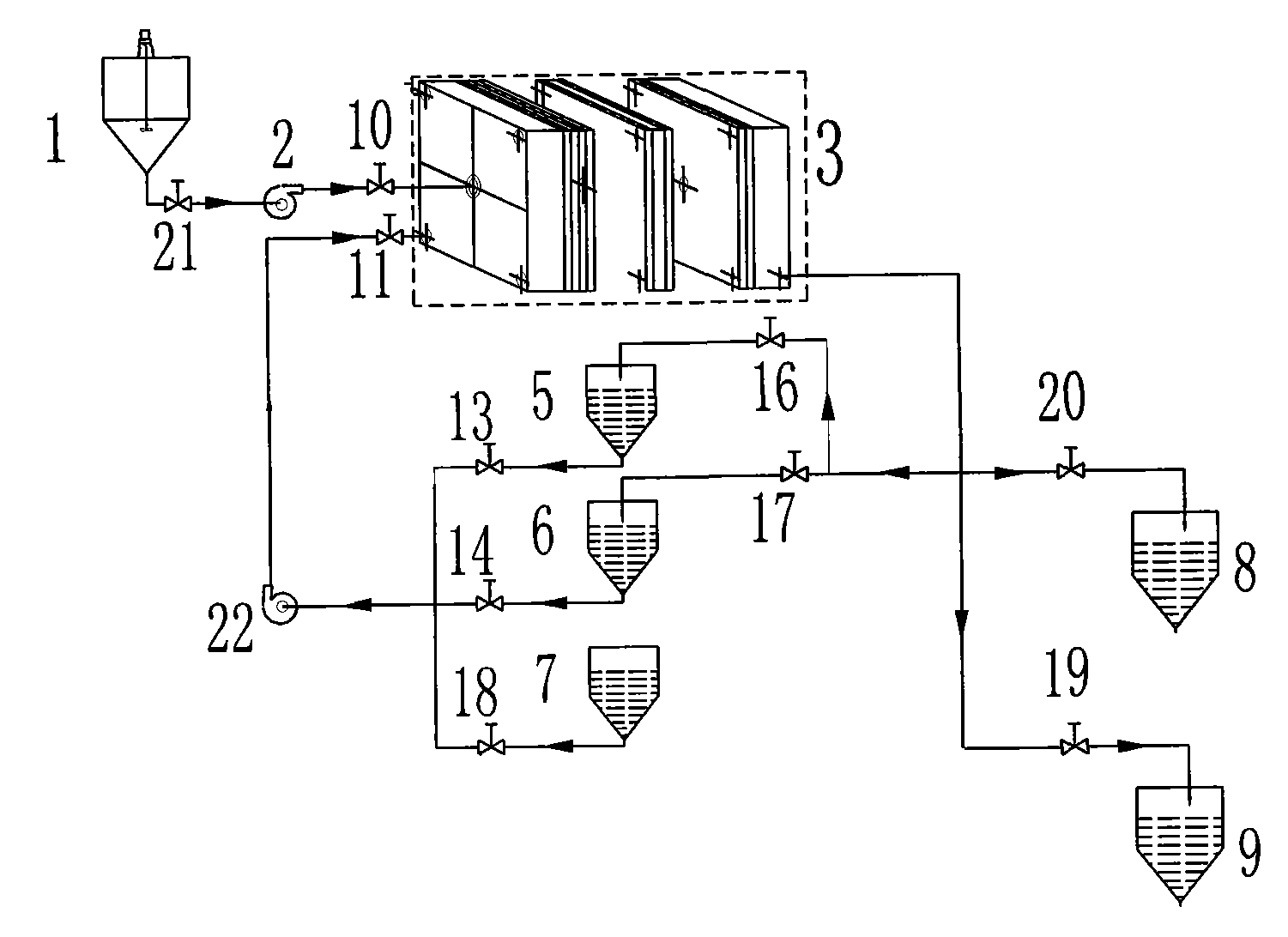

[0062] As another specific embodiment of the present invention, a simplified process of the integrated system of the present invention is used to carry out multi-stage acid leaching, multi-stage countercurrent washing, and pressure filtration integrated treatment on zinc calcine. The zinc calcine used in this embodiment The content of water-soluble zinc in the acidic leaching solution of the first stage of sand is 134g / l (as Zn 2+ ), the content of undissolved zinc in the residual zinc slag filter cake after acid leaching is 17.4%, and the content of water-soluble zinc is 4.3% (in terms of Zn), such as figure 2 As shown, the specific implementation steps are as follows:

[0063] 1) Open the control valves 10, 20, 21 and the pump 2, inject the zinc calcine in the feeding tank 1 into the membrane filter press 3 directly, and the filter press fluid flows into the filtrate pool 8, when the filter residue fills the entire membrane filter press When the filter plate chamber of the...

Embodiment 3

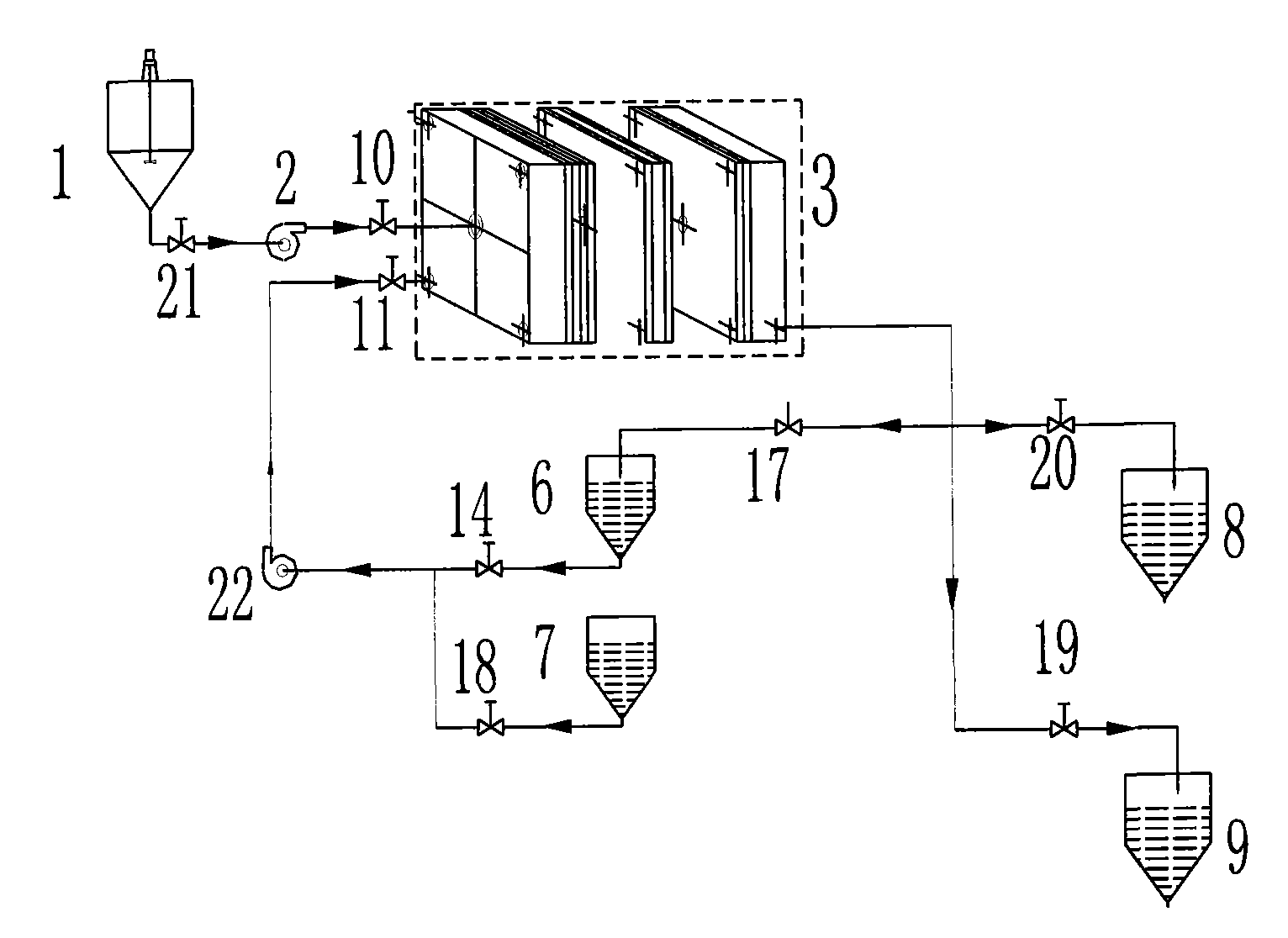

[0072] As another specific embodiment of the present invention, another simplified process of the integrated system of the present invention is used to carry out the integrated treatment of secondary countercurrent washing and pressure filtration on the zinc calcine, and the water-soluble The content of zinc is 131g / l (as Zn 2+ meter), the water-soluble zinc content in the residual zinc slag filter cake after acid leaching is 4.7% (in terms of Zn), such as image 3 As shown, the specific implementation steps are as follows:

[0073] 1) Open the control valves 10, 20, 21 and the pump 2, inject the zinc calcined sand leachate in the feeding tank 1 directly into the diaphragm filter press 3, and the press filter liquid flows into the filtrate pool 8, when the filter residue fills the entire diaphragm filter press 3 When the filter plate chamber is closed, close the pump 2 and close the control valves 10, 20, 21;

[0074]2) Open the control valves 11, 14 and 17, open the pump 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com