Production method of natural stone texture imitating ceramic wall ground tile

A technology imitating natural stone and production methods, which is applied in the field of production of ceramic wall and floor tiles imitating natural stone texture, can solve the problems of fineness, layering, color transition, and natural lines that do not conform to the national regulations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

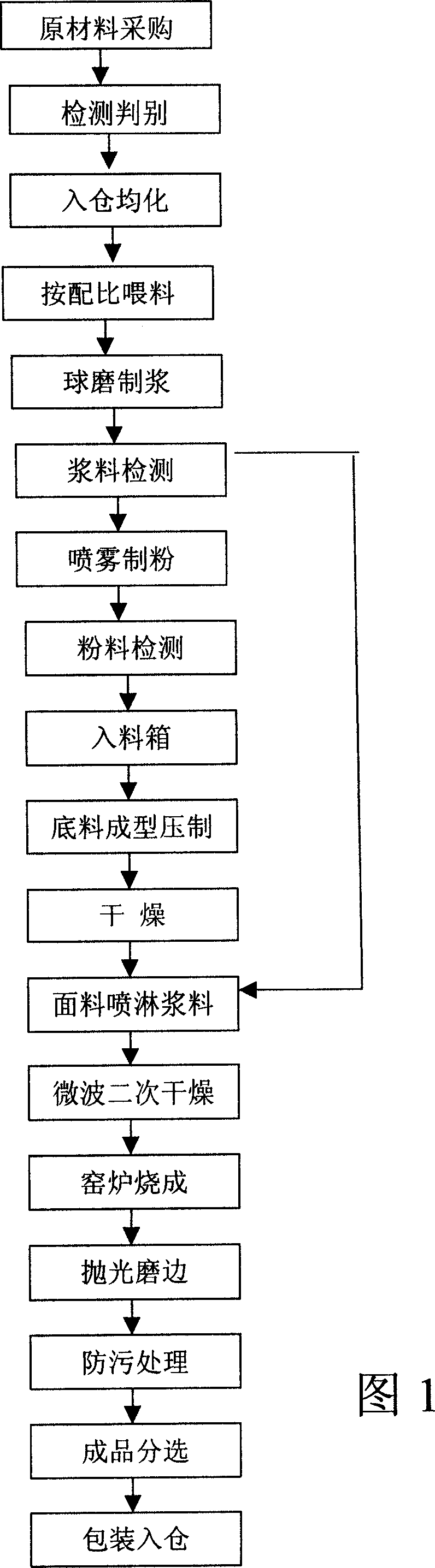

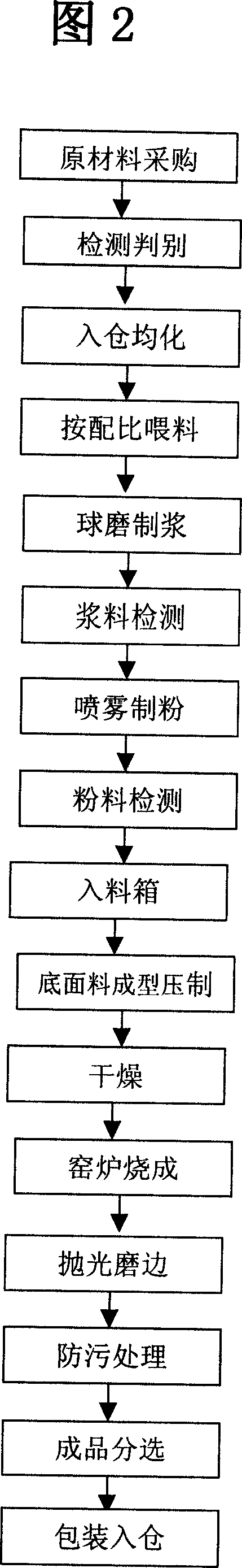

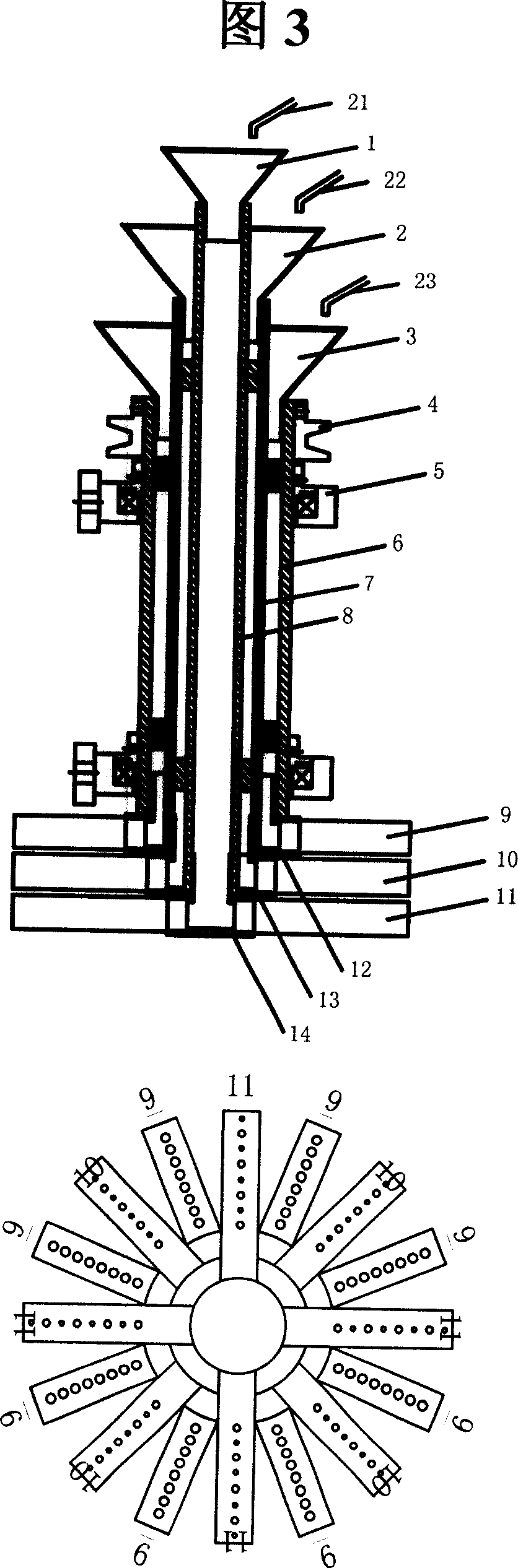

[0094] The production method of polished ceramic wall and floor tiles imitating the texture of natural stone is to use ceramic slurry of various colors, in a mixed or semi-mixed state, to spray or glaze on the surface of the dried bricks, and then microwave-dried and put into the kiln Calcined in a furnace to make ceramic wall and floor tiles with natural texture and effect similar to natural stone,

[0095] It is characterized in that: the method has the following steps:

[0096] (1) 10% by weight of quartz, 10% by weight of kaolin, and 80% by weight of mixed sand are mixed into a ball mill for wet ball milling. The amount of water added during ball milling is calculated as : 25% by weight, after passing through a 120-mesh sieve, slurry-like surface glaze slurry is made;

[0097] (2) Configure multi-colored ceramic slurry: add colorants of various colors bought from the market in the slurry prepared above, and the amount of colorant added is 0.05% to 5% of the total weight o...

Embodiment 2

[0105] The production method of polished ceramic wall and floor tiles imitating the texture of natural stone is to use ceramic slurry of various colors, in a mixed or semi-mixed state, to spray or glaze on the surface of the dried bricks, and then microwave-dried and put into the kiln Calcined in a furnace to make ceramic wall and floor tiles with natural texture and effect similar to natural stone,

[0106] It is characterized in that: the method has the following steps:

[0107] (1) 30% by weight of quartz, 30% by weight of kaolin, and 40% by weight of mixed sand are mixed into the ball mill for wet ball milling. The amount of water added during ball milling is calculated as : 35% by weight, made into paste-like surface glaze slurry after passing through a 180-mesh sieve;

[0108] (2) Configure multi-colored ceramic slurry: add colorants of various colors bought from the market in the slurry prepared above, and the amount of colorant added is 0.05% to 5% of the total weight...

Embodiment 3

[0116] The production method of ceramic wall and floor tiles imitating natural stone texture is to use various colors of ceramic slurry, in a mixed or semi-mixed state, spray or pour glaze on the surface of the dried brick, dry it with microwave ovens, and then put it into the kiln for calcination. Made of ceramic wall and floor tiles with natural texture and effect similar to natural stone,

[0117] It is characterized in that: the method has the following steps:

[0118] (1) 15% by weight of quartz, 15% by weight of kaolin, and 70% by weight of mixed sand are mixed into the ball mill for wet ball milling. The amount of water added during ball milling is calculated as : 25% by weight, made into paste-like surface glaze slurry after passing through a 180-mesh sieve;

[0119] (2) Configure multi-colored ceramic slurry: add colorants of various colors bought from the market in the slurry prepared above, and the amount of colorant added is 0.05% to 5% of the total weight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com