High-quality epoxy ester production method with low energy consumption and little wastewater

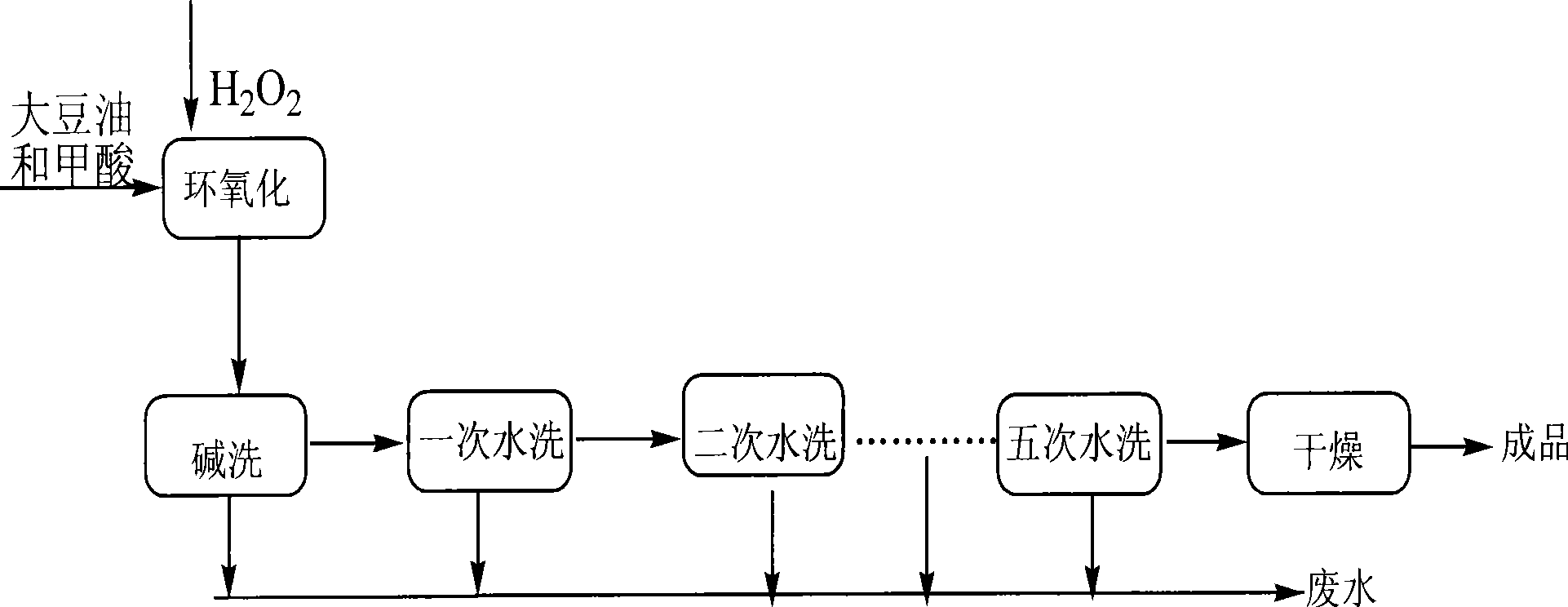

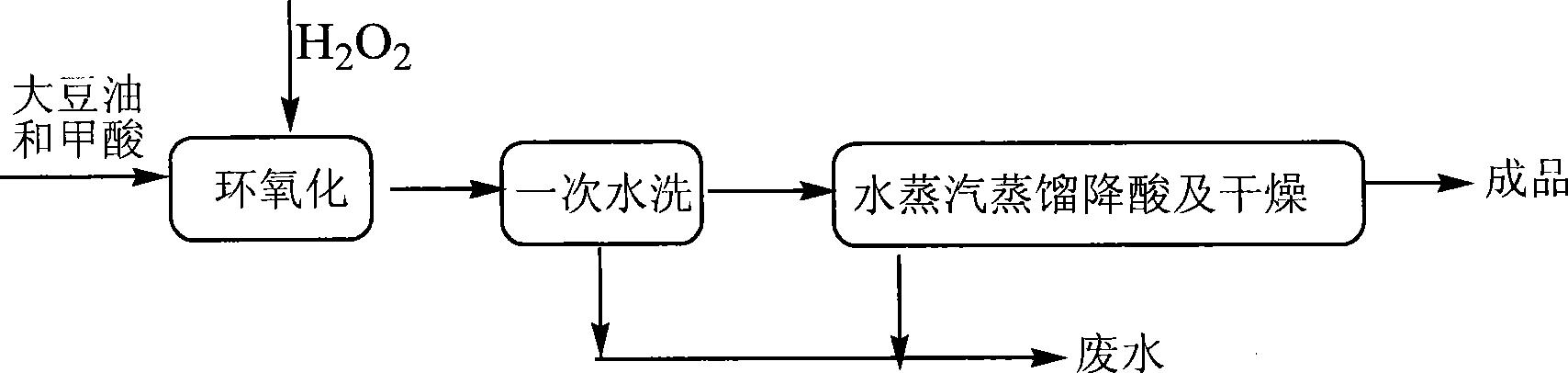

A technology of epoxy oil ester and production method, which is applied in the direction of organic chemistry, can solve problems such as separation difficulties, emulsification, loss of materials and time, and achieve the effects of reducing material consumption, energy consumption, and waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Press soybean oil: hydrogen peroxide: the weight ratio of formic acid=1:1.0:0.15, take by weighing a certain amount of iodine value 130gI2 / 100g soybean oil and 85% formic acid are placed in stirrer, thermometer, the there-necked flask of dropping funnel In the process, the three-neck flask is placed in a water bath system with automatic temperature control, stirred, and 35% hydrogen peroxide is added dropwise, and the drop is completed in 5-10 minutes. After the temperature rises to 60°C, the heat preservation is started. The heat preservation time is 5 hours, and the epoxidation reaction is completed. . Transfer the reaction mixture to a separatory funnel, let it stand for a while to separate the water layer, wash the ester layer with distilled water at about 70°C once, the water consumption is about 40% of the volume of the ester layer, and then distill the product with steam distillation for 3 to 4 hours The depth is acid-reduced and dried, and the product epoxidized...

Embodiment 2

[0020] By fatty acid methyl ester: hydrogen peroxide: the weight ratio of formic acid=1:0.55:0.15, take by weighing a certain amount of fatty acid methyl ester (iodine value 120gI 2 / 100g) and 85% formic acid are placed with agitator, thermometer, in the three-necked flask of dropping funnel, and the three-necked flask is placed in the water bath system with automatic temperature control, stirs, drips the hydrogen peroxide of 35%, 5- After 10 minutes of dripping, the temperature rises to 60° C. and then heat preservation is started. The heat preservation time is 4 hours, and the epoxidation reaction ends. Transfer the reaction mixture to a separatory funnel, let it stand for a while to separate the water layer, wash the ester layer with distilled water at about 70°C once, the water consumption is about 40% of the volume of the ester layer, and then distill the product with steam distillation for 3 to 4 hours Depth deacidification is dried, and product epoxy fatty acid methyl e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com